Method for preparing disproportionated rosin with high dehydroabietic acid content

A technology of disproportionated rosin and dehydroabietic acid, which is applied in the field of rosin processing, can solve the problems of high energy consumption, light color of disproportionated rosin, and the need for distillation, etc., and achieve the effects of high content of dehydroabietic acid, increased added value, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

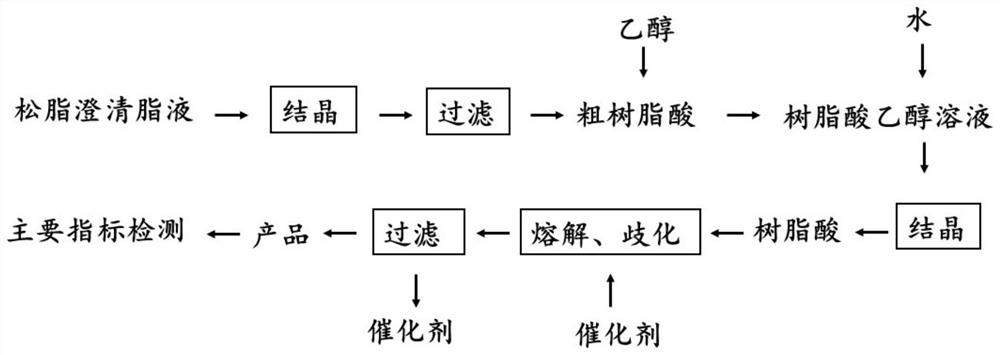

Image

Examples

Embodiment 1

[0027] Put the turpentine into the turpentine tank after crushing, add tap water until the water surface is 10cm above the turpentine surface for maintenance, send the turpentine in the resin storage tank to the dissolving kettle when dissolving, add turpentine to make the oily quality of the clarified fat liquid reach 32%, add the quality of turpentine 8% water with a temperature of 80°C, adding 0.18% oxalic acid in the mass of turpentine, passing through water vapor, heating at 94°C, mixing and dissolving, filtering and clarifying to obtain a clear fat liquid;

[0028] The clarified fat liquid is naturally aged for 30 days, after the natural crystallization of crude resin acid crystals, the crude resin acid crystals are obtained by filtration, and the crude resin acid crystals are dissolved with absolute ethanol with a solid-to-liquid ratio of 1:1 (g / mL), and then Water is added, the volume ratio of water to ethanol is 3:10, the temperature is controlled at 0°C, and the time ...

Embodiment 2

[0031] Put the turpentine into the turpentine tank after crushing, add tap water until the water surface exceeds the rosin surface by 20cm for maintenance, send the turpentine in the tank to the dissolving kettle when dissolving, add turpentine to make the oily quality of the clarified fat liquid reach 36%, add the quality of turpentine 15% of water at a temperature of 90°C, adding 0.2% oxalic acid in the mass of turpentine, passing through water vapor, heating at 95°C, mixing and dissolving, filtering and clarifying to obtain a clear fat liquid;

[0032] The clarified fat liquid is naturally aged for 60 days, after natural crystallization and thick resin acid crystals, filter out the thick resin acid crystals, dissolve the thick resin acid crystals with absolute ethanol with a solid-to-liquid ratio of 1:1.2 (g / mL), and then go to Add water, the volume ratio of water to ethanol is 1:2, the temperature is controlled at 0°C, and the time is 24h for recrystallization to obtain res...

Embodiment 3

[0035] Put the turpentine into the turpentine pool after crushing, add tap water until the water surface exceeds the rosin surface by 15cm for maintenance, send the turpentine in the rosin pool to the dissolving kettle when dissolving, add turpentine to make the oily quality of the clarified fat liquid reach 34%, add the turpentine quality 10% water with a temperature of 85°C, adding 0.15% oxalic acid in the mass of turpentine, passing through water vapor, heating at 94°C, mixing and dissolving, filtering and clarifying to obtain a clear fat liquid;

[0036] Put the clarified fat liquid naturally for 40 days, after natural crystallization and precipitation of crude resin acid crystals, filter to obtain crude resin acid crystals, and dehydrated alcohol dissolves the crude resin acid crystals with a solid-to-liquid ratio of 1:1.2 (g / mL), and then pour them into Add water, the volume ratio of water to ethanol is 2:5, the temperature is controlled at 10°C, and the time is 12h for r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com