Method for in-situ catalytic chemical plating of plasma modified polyimide film

A technology of polyimide film and in-situ catalysis, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., to achieve good wettability, conducive to circuit forming, and good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

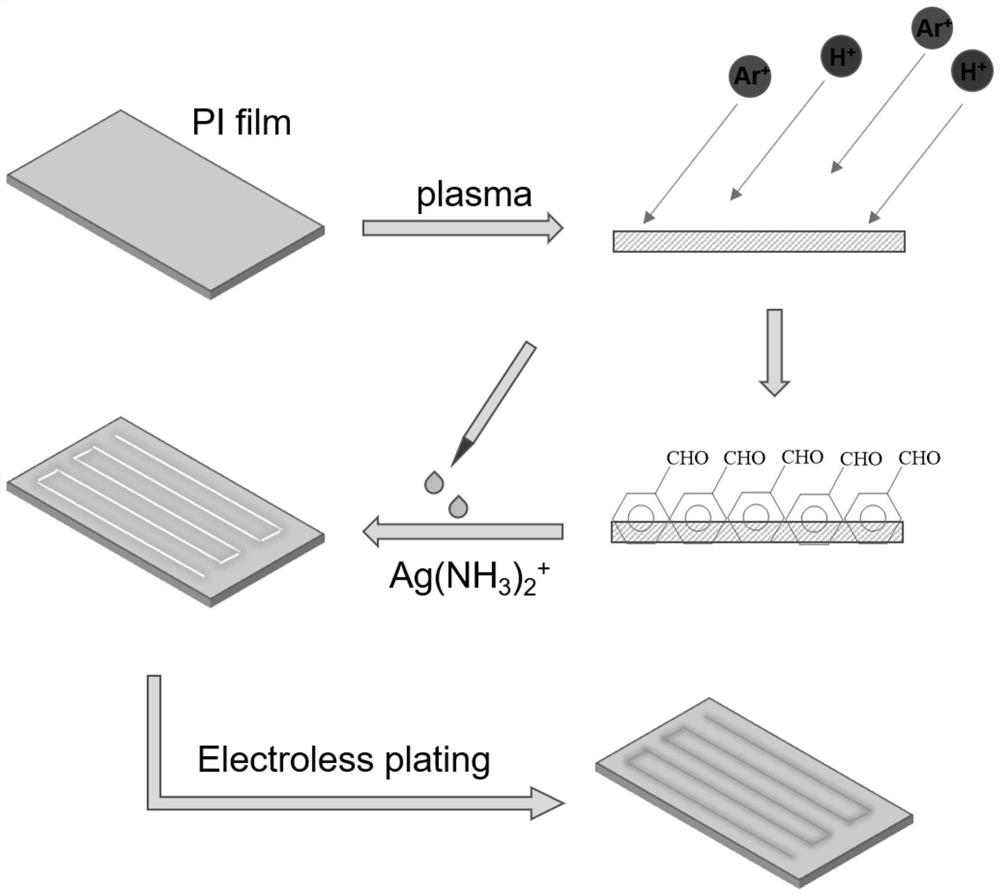

Method used

Image

Examples

preparation example Construction

[0035] (2) Preparation of silver ammonia solution: take appropriate amount of ammonia water for experiment, add deionized water to dilute, and prepare 0.05-0.15mol / L silver nitrate solution, take it out into a test tube, and add diluted ammonia drop by drop to the test tube Aqueous solution, while dripping while oscillating, brown flocculent precipitates are formed when just dropping, continue to drop and oscillate until the precipitate disappears completely, and obtain a colorless transparent solution; the silver ammonia solution in step (2) has a mass concentration of 3%-5 Ammonia or sodium hydroxide solution in the range of % is added dropwise to the silver nitrate solution, from clear to turbid and then back to a colorless transparent solution state, the concentration of silver nitrate is 0.05-0.15mol / L.

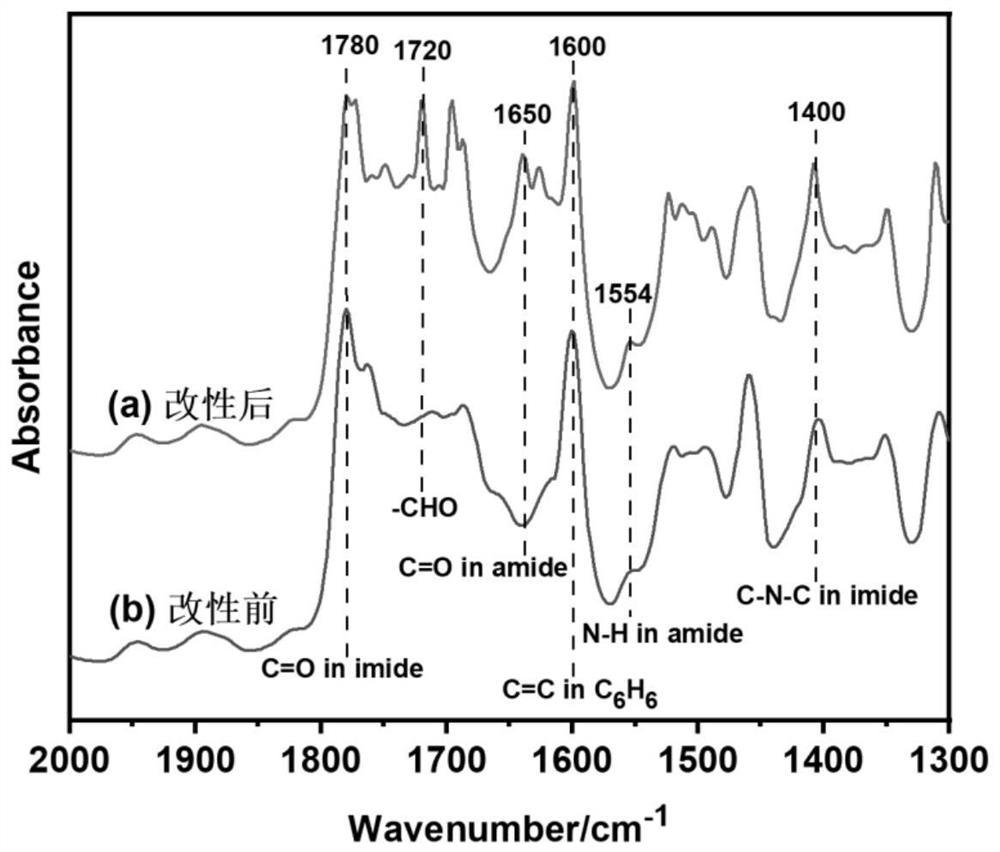

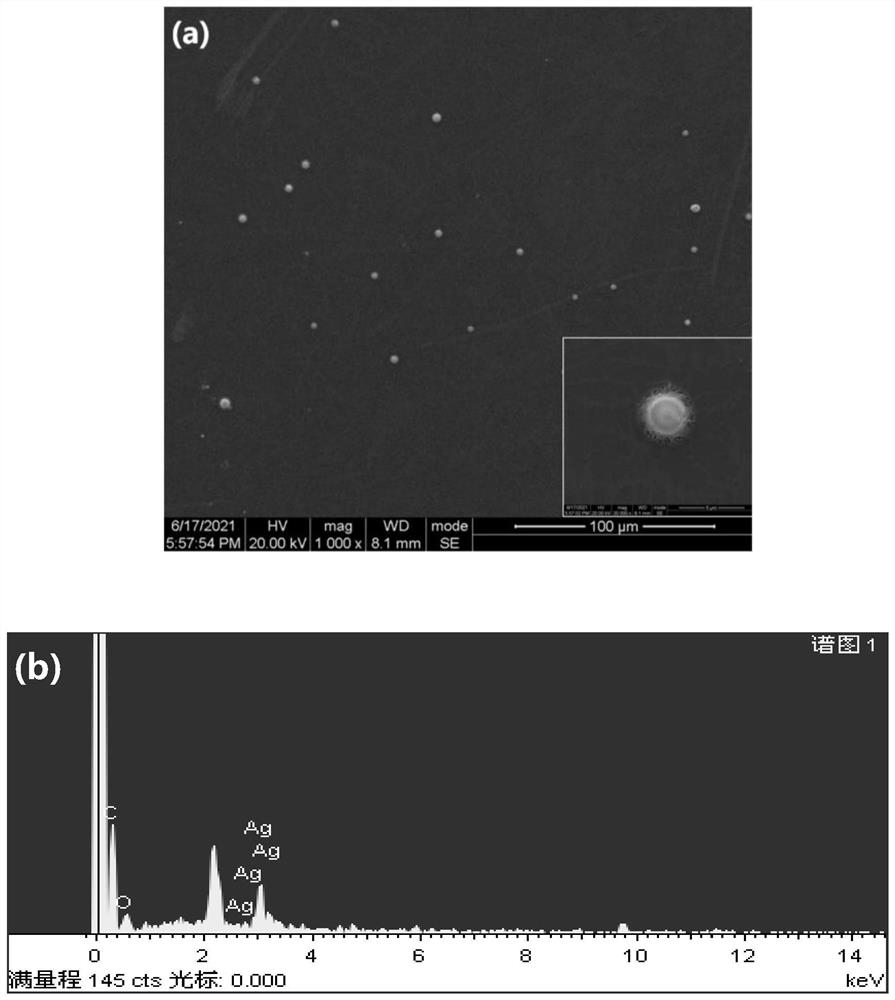

[0036] (3) Plasma modification of polyimide: put the clean polyimide film obtained in (1) into the chamber of the plasma equipment, set the relevant parameters of the pla...

Embodiment 1

[0041] (1) Cleaning of polyimide: Take the kapton polyimide film developed by DuPont Company, with a length and width of 7×3cm and a thickness of 0.125mm, and place it in absolute ethanol for ultrasonic cleaning for 5min, with an ultrasonic power of 110W , the frequency is 40KHz, and then washed with a large amount of deionized water, and then dried to obtain a clean PI film. The kapton process polyimide film developed by DuPont is an aromatic polyimide film material with imide ring as the characteristic functional group on the main chain.

[0042] (2) Preparation of silver-ammonia solution: measure 1ml mass concentration of 25% ammonia solution, add 4ml deionized water to dilute to obtain 5% ammonia solution (A), weigh 0.17g silver nitrate and add 10ml deionized water Ionized water to obtain a silver nitrate solution (B) with a molar concentration of 0.1mol / L, take 1ml of the silver nitrate (B) solution in a clean test tube, and add the diluted ammonia solution (A) drop by dr...

Embodiment 2

[0047] (1) Cleaning of polyimide: take the kapton polyimide film developed by DuPont Company, with a length and width of 7 cm x 7 cm and a thickness of 0.125 mm, and place it in absolute ethanol for ultrasonic cleaning for 10 min, with an ultrasonic power of 110 W , the frequency is 40KHz, and then washed with a large amount of deionized water, and then dried to obtain a clean PI film.

[0048] (2) The preparation of silver ammonia solution: measure 1ml mass concentration and be 25% sodium hydroxide solution (A), add 8ml deionized water to dilute and obtain mass concentration and be 3%, take by weighing 0.17g silver nitrate and add 10ml deionized Water to obtain a silver nitrate solution (B) with a molar concentration of 0.1mol / L, take 1ml of the silver nitrate (B) solution in a clean test tube, add the diluted sodium hydroxide solution (A) drop by drop to the test tube, and drop While oscillating, a brown flocculent precipitate was formed at the beginning of the dropwise addi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com