Resin composition, prepreg, laminate, multilayer printed wiring board, and semiconductor package

A resin composition and compound technology, which is applied in the fields of multilayer printed wiring boards and semiconductor packages, laminates, prepregs, and resin compositions, can solve the problem of poor dielectric properties, increased dielectric properties of printed wiring boards, Insufficient dielectric properties of printed wiring boards, etc., to achieve the effect of sufficient flame retardancy and excellent dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0402] Hereinafter, the present invention will be described concretely with reference to examples. However, the present invention is not limited to the following examples.

[0403] In addition, in each example, weight average molecular weight (Mw) was measured by the following method.

[0404] Conversion was performed by gel permeation chromatography (GPC) based on a calibration curve using standard polystyrene. The standard curve uses standard polystyrene: TSK standard POLYSTYRENE (Type; A-2500, A-5000, F-1, F-2, F-4, F-10, F-20, F-40) [Tosoh Corporation Company system, product name], approximated by a cubic formula. The measurement conditions of GPC are shown below.

[0405] device:

[0406] Pump: Model L-6200 [manufactured by Hitachi High-Tech Co., Ltd.]

[0407] Detector: L-3300 type RI [manufactured by Hitachi High-Tech Co., Ltd.]

[0408] Column oven: L-655A-52 [manufactured by Hitachi High-Tech Co., Ltd.]

[0409] Column: guard column; TSK Guardcolumn HHR-L+ colu...

manufacture example 1

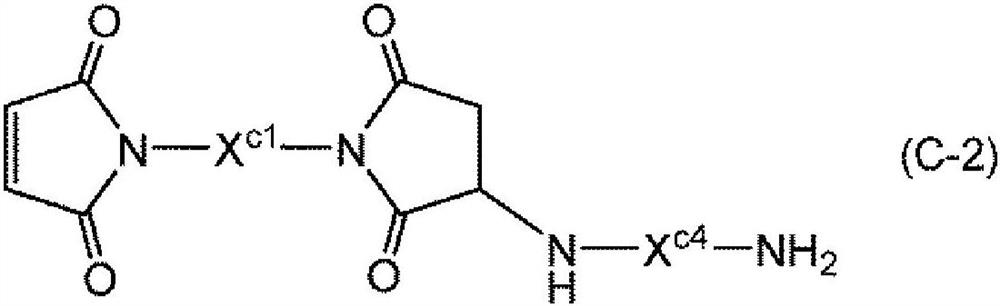

[0416] [Production Example 1: Production of Modified Maleimide Compound (X-1)]

[0417] Put 2,2-bis[4-(4-maleimidephenoxy) in a reaction vessel with a volume of 5 liters capable of heating and cooling attached to a moisture meter with a thermometer, a stirring device, and a reflux condenser. ) 100 parts by mass of phenyl] propane, 5.6 parts by mass of siloxane compound (functional group equivalent weight 750 g / mol) having amino groups at both ends, 3,3'-diethyl-4,4'-diaminodiphenylmethane 7.9 parts by mass and 171 parts by mass of propylene glycol monomethyl ether were reacted for 2 hours while refluxing. This was concentrated at reflux temperature over 3 hours to produce a modified maleimide compound (X-1) solution having a solid content concentration of 65% by mass. The weight average molecular weight (Mw) of the obtained modified maleimide compound (X-1) was about 2700.

Embodiment 1 and 2、 comparative example 1~6

[0419] Each component described in Table 1 was stirred and mixed at room temperature with 58 parts by mass of toluene and 10 parts by mass of methyl isobutyl ketone according to the compounding composition described in Table 1 to prepare a resin having a solid content concentration of 55 to 65 mass % combination.

[0420] The resin composition obtained in each example was coated on glass fiber cloth (E glass, manufactured by Nitto Boshen Co., Ltd.) with a thickness of 0.08 mm, and then heated and dried at 150° C. for 5 minutes to prepare a solid material derived from the resin composition. A prepreg having a component content of about 47% by mass. On the upper and lower sides of the prepreg, a low-smoothness copper foil (BF-ANP18, Rz of the M surface: 1.5 μm, manufactured by CIRCUIT FOIL Co., Ltd.) with a thickness of 18 μm is arranged so that the M surface is in contact with the prepreg, and the temperature is 230 ° C. , pressure 3.0MPa, time 90 minutes under the conditions ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com