Process for continuously preparing calcium sulfate hemihydrate and calcium sulfate dihydrate whiskers from salty mud

A technology of calcium sulfate dihydrate and whiskers, which is applied in the directions of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of complicated steps and time-consuming pretreatment, and achieves the requirements of reducing equipment, simplifying the process, and reducing the reaction time. mild effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

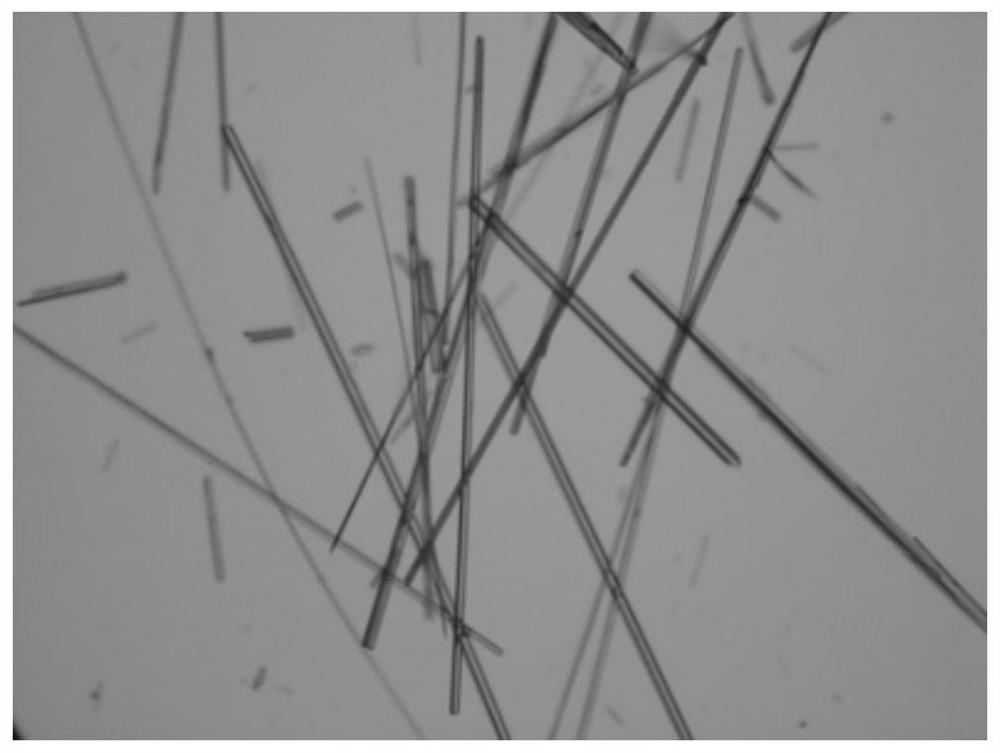

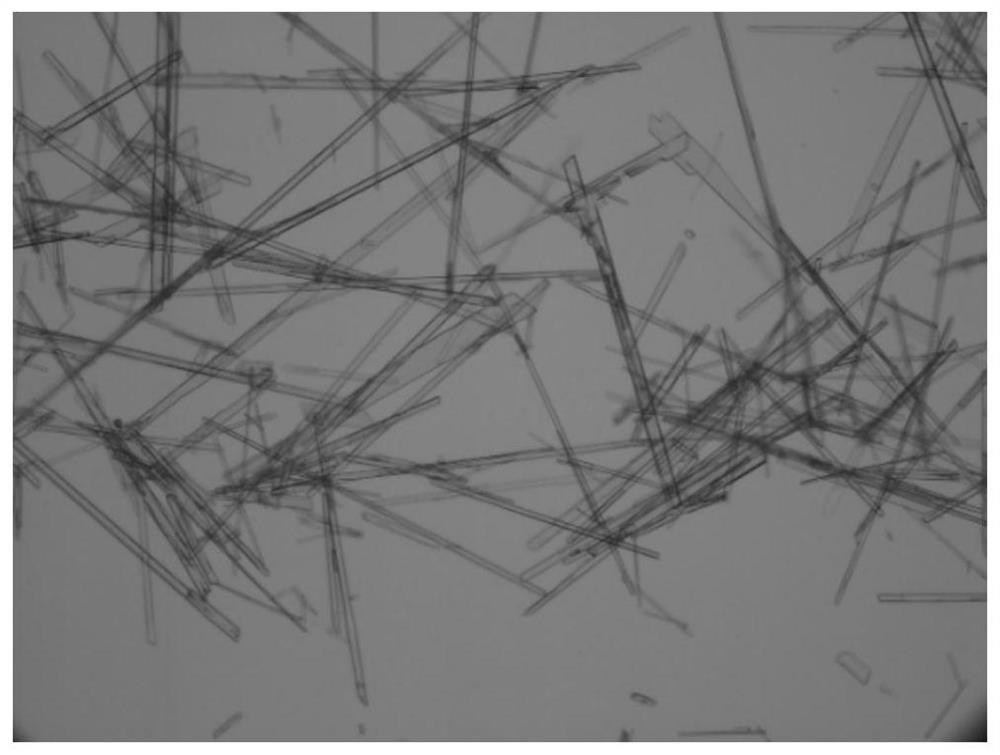

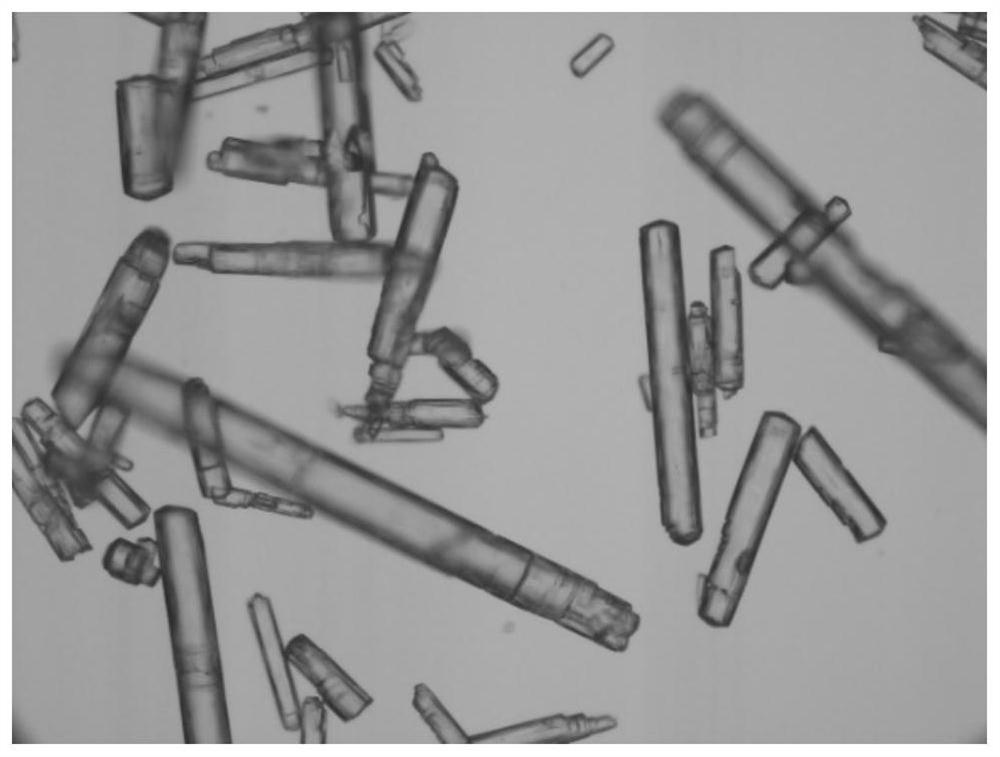

Image

Examples

Embodiment 1

[0039] The composition of the salt mud used in the present embodiment is calculated in parts by weight: CaCO 3 : 64.8%, H 2 O: 23.5%, CaSO 4 : 9.2%, Mg(OH) 2 : 1.4%, NaCl: 0.5%, and the rest is SS.

[0040] (1), drip hydrochloric acid (mass fraction is 21%) to above-mentioned 100g salt mud until reaction system does not have bubble to occur;

[0041] (2) Filter the reaction system obtained in step (1), and measure the concentration of metal ions therein.

[0042] (3), the filtrate obtained in the step (2) is diluted to a calcium ion concentration of 0.5mol / L, and a magnesium ion concentration of 0.015mol / L, then adding concentrated hydrochloric acid to adjust the pH to 0.2.

[0043](4) Add the solution obtained in step (3) together with an equimolar and equal volume of sodium sulfate solution into a thick-walled pressure-resistant bottle, heat to 130° C., and the reaction time is 3 hours.

[0044] (5), after the reaction in step (4), filter while hot and collect filtrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com