Polyimide nano cobweb fiber filtering membrane and preparation method thereof

A technology of polyimide fiber and fiber filter membrane, which is applied in the field of polyimide nano-spider fiber filter membrane and its preparation, and can solve the problems of low filtration efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

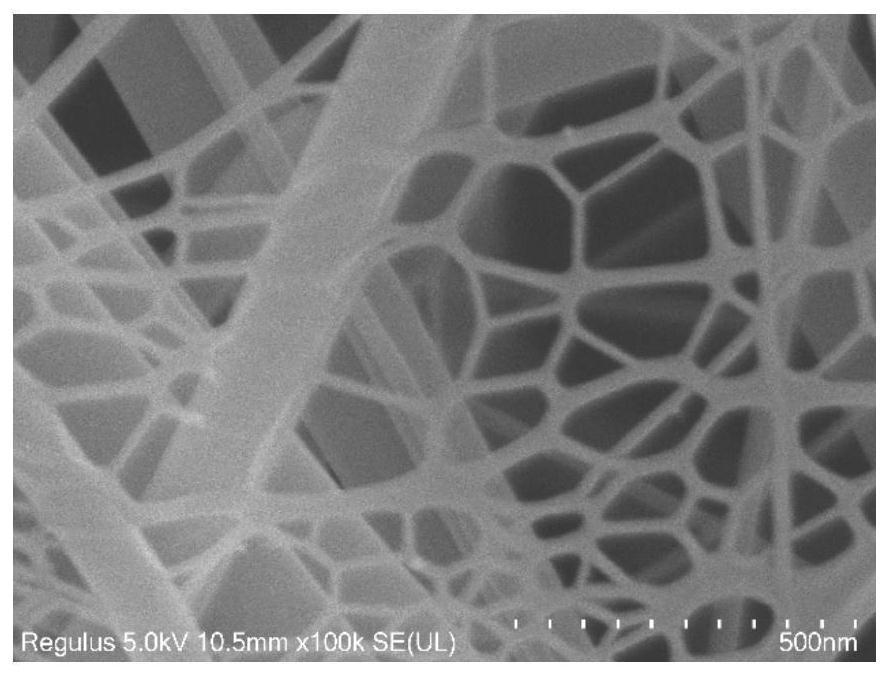

Image

Examples

preparation example Construction

[0022] The invention provides a preparation method of a polyimide nano-cobweb fiber filter membrane with excellent high-temperature and high-efficiency filtration performance, and the specific steps are as follows:

[0023] (1) Dissolve 10~30g 4,4'-diaminodiphenyl ether (ODA) in 100~300mL N,N-dimethylformamide (DMF), slowly add 10.5~31.5g pyromellitic anhydride ( PMDA), stirring at 0-4 ℃ for 12-24 h, the polyamic acid (PAA) precursor solution was obtained by low-temperature polycondensation reaction;

[0024] (2) Add 0.003-0.01 g of lithium chloride to 10 mL of polyamic acid precursor solution, and mix uniformly to form a spinning solution;

[0025] (3) Take 3-10 mL of the spinning solution to be spun into a syringe, the voltage is 25-30 kV, the speed of the propeller is 0.2-0.5 mL / h, and spin to form a film to obtain a polyimide fiber film with a spider web structure ;

[0026] (4) drying the polyimide fiber membrane with spider web structure prepared in (3) in an oven at 6...

Embodiment 1

[0031] (1) Dissolve 10 g of 4,4'-diaminodiphenyl ether (ODA) in 100 mL of N-N dimethylformamide (DMF), slowly add 10.5 g of pyromellitic anhydride (PMDA), and stir at 4°C 12h, the polyamic acid (PAA) precursor solution was prepared;

[0032] (2) adding 0.003 g of lithium chloride to 10 mL of polyamic acid precursor solution, and mixing uniformly to form a spinning solution;

[0033] (3) take 4mL of spinning solution to be placed in a syringe, the voltage is 28kV, the speed of the propeller is 0.3mL / h, and the spinning is filmed to obtain a polyimide fiber film with a spider web structure;

[0034] (4)) drying the polyimide fiber membrane with spider web structure prepared in (3) in an oven at 60° C. for 24 hours to remove excess solvent;

[0035] (5) The polyimide fiber membrane with spider web structure obtained in (4) was imidized at 25° C. for 3 hours in a tube furnace, and a polyimide nano spider web fiber filter membrane with high temperature and high efficiency filtrati...

Embodiment 2

[0038] (1) Dissolve 30 g of 4,4'-diaminodiphenyl ether (ODA) in 300 mL of N-N dimethylformamide (DMF), slowly add 20 g of pyromellitic anhydride (PMDA), and stir at 0°C for 24 h , to prepare polyamic acid (PAA) precursor solution;

[0039] (2) adding 0.01 g of lithium chloride to 10 mL of polyamic acid precursor solution, and mixing to form a spinning solution;

[0040] (3) get 3mL of spinning solution to be placed in a syringe, the voltage is 30kV, the speed of the propeller is 0.2mL / h, and the spinning is filmed to obtain a polyimide fiber film with a spider web structure;

[0041] (4)) drying the polyimide fiber membrane with spider web structure prepared in (3) in an oven at 60° C. for 12 hours to remove excess solvent;

[0042] (5) The polyimide fiber membrane with spider web structure obtained in (4) was imidized at 300° C. for 4 h in a tube furnace, and a polyimide nano spider web fiber filter membrane with high temperature and high efficiency filtration was successful...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com