Alkali cobalt carbonate@nickel cobalt MOF core-shell array composite material, preparation and application thereof

A composite material, cobalt carbonate technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of poor cycle stability and low energy density of capacitors, and achieve short time consumption and abundant redox reaction sites , good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

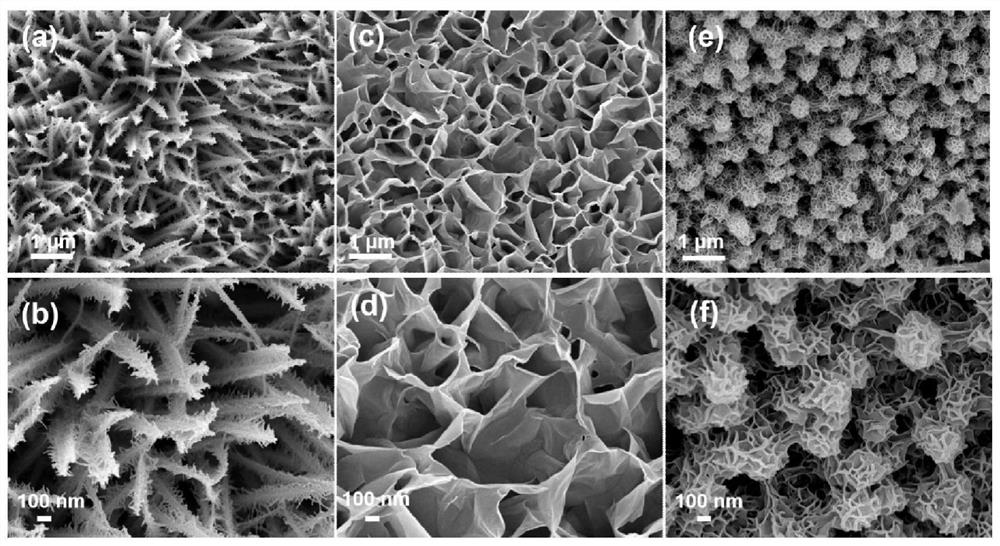

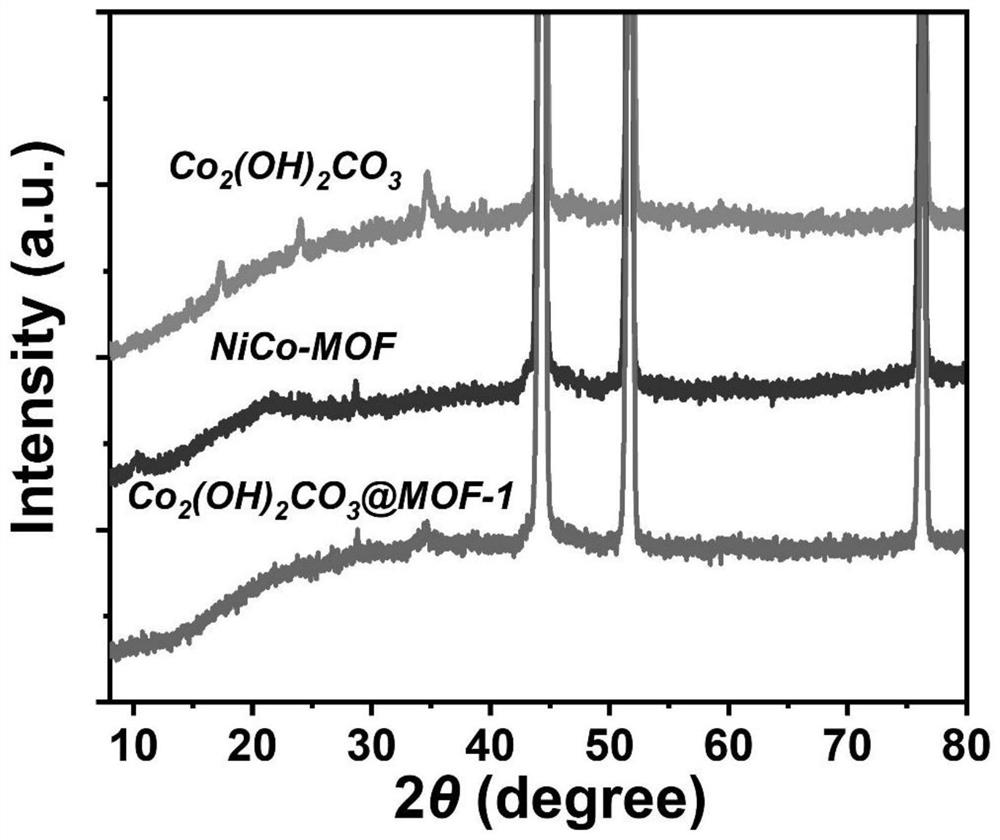

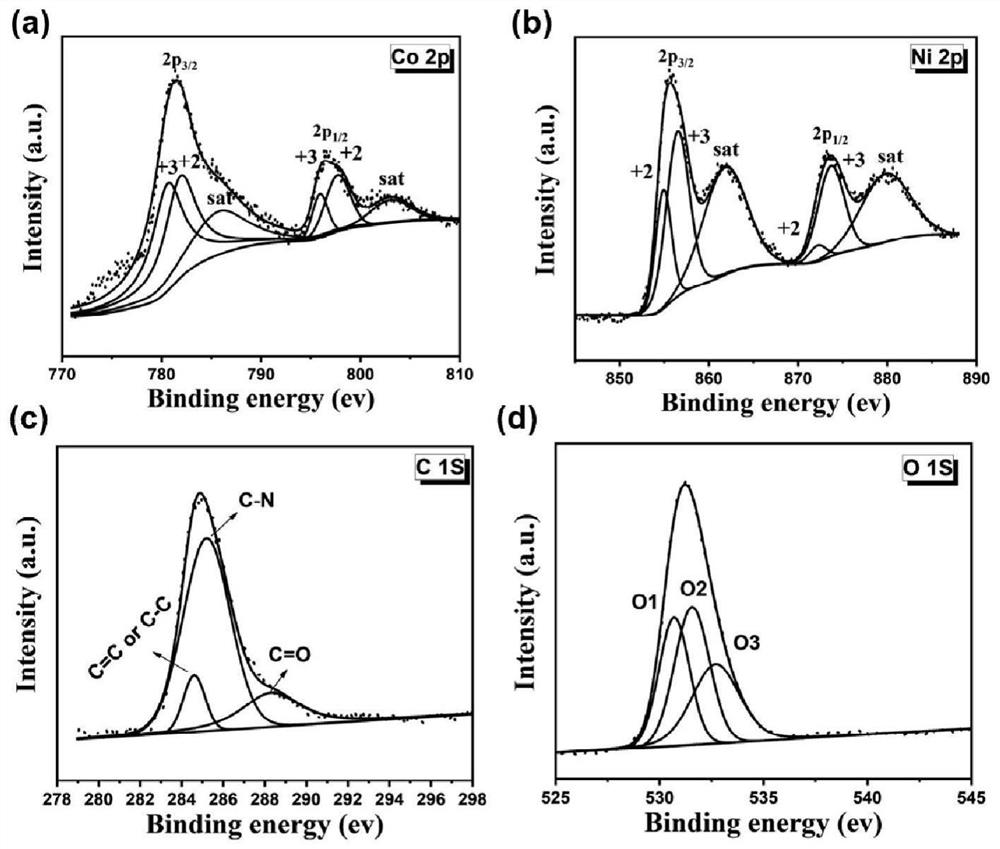

[0040] Example 1: Co 2 (CO 3 ) (OH) 2 @ MOF-1 was prepared and applied to electrode materials for supercapacitors

[0041] The preparation steps of:

[0042] First Weigh Co (NO 3 ) 2 · 6H 2 O (0.5821g, 2mmol), urea (0.6006g, 10mmol), was dissolved in 40mL of deionized water under magnetic stirring action until a deep pink homogeneous solution. The solution was poured into 50mL configured polytetrafluoroethylene autoclave high pressure water, have taken a good pre-drying of the size of 1cm × 4cm foamed nickel autoclave into water, water is sealed in the autoclave under the action of 120 ℃ heated 4h. After the autoclave was water to be cooled to room temperature, remove the nickel foam was rinsed with ethanol and dried in vacuo to obtain Co 2 (CO 3 ) (OH) 2 Precursor.

[0043] Under magnetic stirring Co (NO 3 ) 2 · 6H 2 O (0.0218g, 0.075mmol), and Ni (NO 3 ) 2 · 6H 2 O (0.0218g, 0.075mmol) was dissolved in 30mL of methanol. 10mL of methanol was then added dropwise a solution contain...

Embodiment 2

[0052] Example 2: CO 2 (Co 3 (OH) 2 Preparation of @ MOF-2 and Its Application to Super Capacitor Electrode Materials

[0053] The preparation steps are:

[0054] First weigh CO (NO 3 ) 2 · 6h 2 O (0.5821 g, 2 mmol), urea (0.6006 g, 10 mmol), dissolved in 40 mL of deionized water under the action of magnetic stirring until a uniform solution of deep pink is obtained. Pour the configuration solution into a 50 ml of polytetrafluoroethylene high-pressure hydrophane, take a pre-pretreated dry 1 cm × 4 cm size foam nickel placed in a hydrothermal kettle, and the hydrothermal kettle is sealed Heating at 120 ° C for 4 h. After the water is reduced to room temperature, remove the foam nickel and rinse with ethanol and dry it, it gives CO 2 (Co 3 (OH) 2 Precursor.

[0055] Co (NO) with magnetic stirring 3 ) 2 · 6h 2 O (0.0291G, 0.1mmol) and Ni (NO 3 ) 2 · 6h 2 O (0.0291 g, 0.1 mmol) was dissolved in 30 ml of methanol. A 10 ml of methanol (0.0498 g, 0.3 mmol) was then added dropwise thereto...

Embodiment 3

[0060] Example 3: CO 2 (Co 3 (OH) 2 Preparation of @ MOF-3 and Its Application to Super Capacitor Electrode Materials

[0061] The preparation steps are:

[0062] First weigh CO (NO 3 ) 2 · 6h 2 O (0.5821 g, 2 mmol), urea (0.6006 g, 10 mmol), dissolved in 40 mL of deionized water under the action of magnetic stirring until a uniform solution of deep pink is obtained. Pour the configuration solution into a 50 ml of polytetrafluoroethylene high-pressure hydrophane, take a pre-pretreated dry 1 cm × 4 cm size foam nickel placed in a hydrothermal kettle, and the hydrothermal kettle is sealed Heating at 120 ° C for 4 h. After the water is reduced to room temperature, remove the foam nickel and rinse with ethanol and dry it, it gives CO 2 (Co 3(OH) 2 Precursor.

[0063] Co (NO) with magnetic stirring 3 ) 2 · 6h 2 O (0.0146g, 0.05mmol) and Ni (NO 3 ) 2 · 6h 2 O (0.0145 g, 0.05 mmol) was dissolved in 30 ml of methanol. Then 10 ml of dimethylimidazole (0.00246 g, 0.3 mmol) of methanol solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com