Green production method of carboxylated graphene

A carboxylated graphene, green production technology, applied in the direction of graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of insufficient environmental protection of the production method, high cost of raw materials, poor modification effect, etc., and achieve mechanical property modification Good effect, simple preparation method, good modification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1, the embodiment 25kg graphene oxide by high shear emulsifying machine and a ultrasonic dispersing device running simultaneously dispersed in 600kg water to obtain a graphene oxide dispersion.

[0034] Step 2, the graphene oxide dispersion obtained in the above step after homogenization conveyed to the reaction kettle was heated to 60 ℃, 9kg of citric acid was added, 25g of concentrated sulfuric acid and polyphosphoric acid 2kg, 10H reaction, to obtain a reaction product.

[0035] Step 3, after the reaction the reaction product was added to water, subjected to suction filtration, washed, filtered to obtain the product.

[0036] Step 4, by sonication, shear, emulsification product was filtered composite dispersion manner dispersed in deionized water to give a slurry graphene carboxy, and finally freeze-dried to obtain the carboxylated graphene powder.

Embodiment 2

[0038] Step 1, the graphene oxide 25kg by sonication, shear, emulsifying compound dispersed in a distributed manner 500kg of water to obtain a graphene oxide dispersion.

[0039] Step 2, the graphene oxide dispersion obtained in the above step after homogenization conveyed to the reaction kettle was heated to 80 ℃, citric acid was added 10kg, 20g 2.5kg of concentrated sulfuric acid and polyphosphoric acid, the reaction 4h, to obtain a reaction product.

[0040] Step 3, after the reaction the reaction product was added to water, subjected to suction filtration, washed, filtered to obtain the product.

[0041] Step 4, by sonication, shear, emulsification product was filtered composite dispersion manner dispersed in deionized water to give a slurry graphene carboxy, and finally freeze-dried to obtain the carboxylated graphene powder.

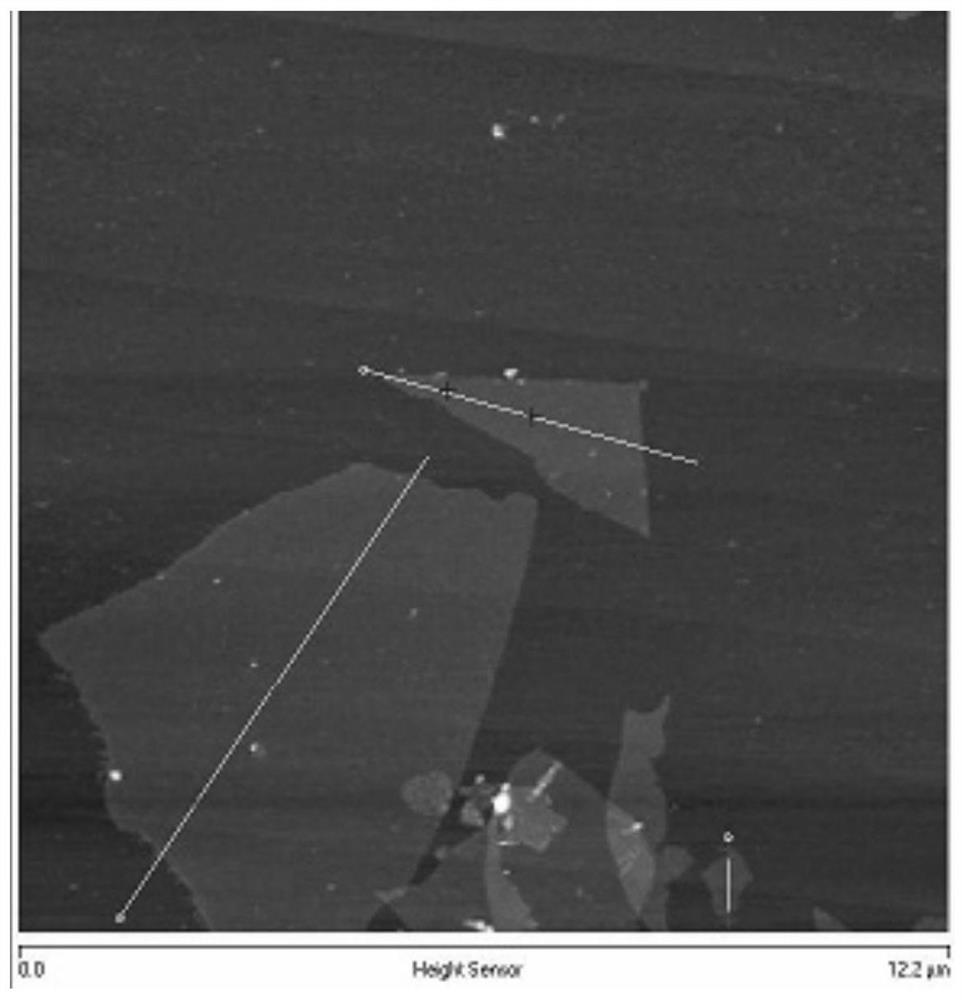

[0042] like figure 1 Shows an atomic force microscope photograph carboxyl graphene prepared in Example 2, can be seen from the photograph, particle di...

Embodiment 3

[0044] Step 1, the graphene oxide 25kg by sonication, shear, emulsifying compound dispersed in a distributed manner 600kg of ethylene glycol, to obtain graphene oxide dispersion.

[0045] Step 2, the graphene oxide dispersion obtained in the above step after homogenization conveyed to the reaction kettle was heated to 80 ℃, 9.6kg of citric acid was added, 25g of concentrated sulfuric acid and polyphosphoric acid 1kg, reaction 5h, to obtain a reaction product.

[0046] Step 3, after the reaction was added to the reaction product of ethylene glycol, subjected to suction filtration, washed, filtered to obtain the product.

[0047] Step 4, by sonication, shear, emulsification product was filtered composite dispersion manner dispersed in ethylene glycol, to obtain graphene carboxy slurry, and finally freeze-dried to obtain the carboxylated graphene powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com