A kind of preparation method of molybdenum disulfide co-doped with fluorine and nitrogen

A technology of molybdenum disulfide and co-doping, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of difficult wide application and complicated operation, and achieve cost reduction and simple operation process , to avoid the effects of post-processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 0.35 grams of sodium molybdate, 2 grams of thiourea, 0.7 grams of ammonium fluoride, and 45 ml of water into a stainless steel reactor with a volume of 75 ml, stir for 30 minutes, seal it, and fill it with 60%; In a crucible boiler, heat at 350° C. for 6 hours, then allow the reaction kettle to cool down to room temperature naturally, and take out the mixture. The above mixture was washed 6 times successively with absolute ethanol, 0.5 mol / liter of dilute hydrochloric acid and distilled water, filtered, and then placed in a vacuum drying oven with a vacuum degree of -1Mpa and vacuum-dried at 70°C for 12 hours to obtain Fluorine and nitrogen co-doped molybdenum disulfide with excellent catalytic activity for hydrogen production from water electrolysis.

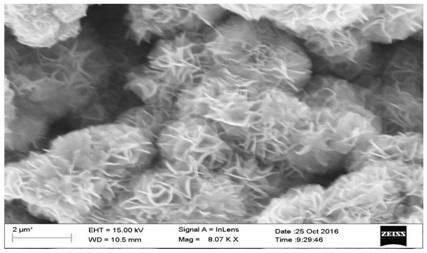

[0024] Such as figure 1 As shown, it can be clearly seen that fluorine and nitrogen co-doped molybdenum disulfide are in the shape of petal balls, and the petal balls are stacked by flakes.

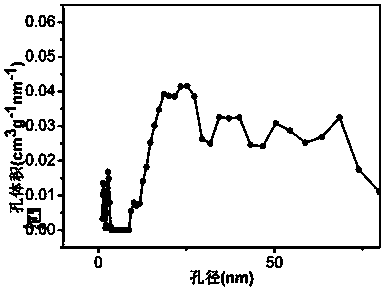

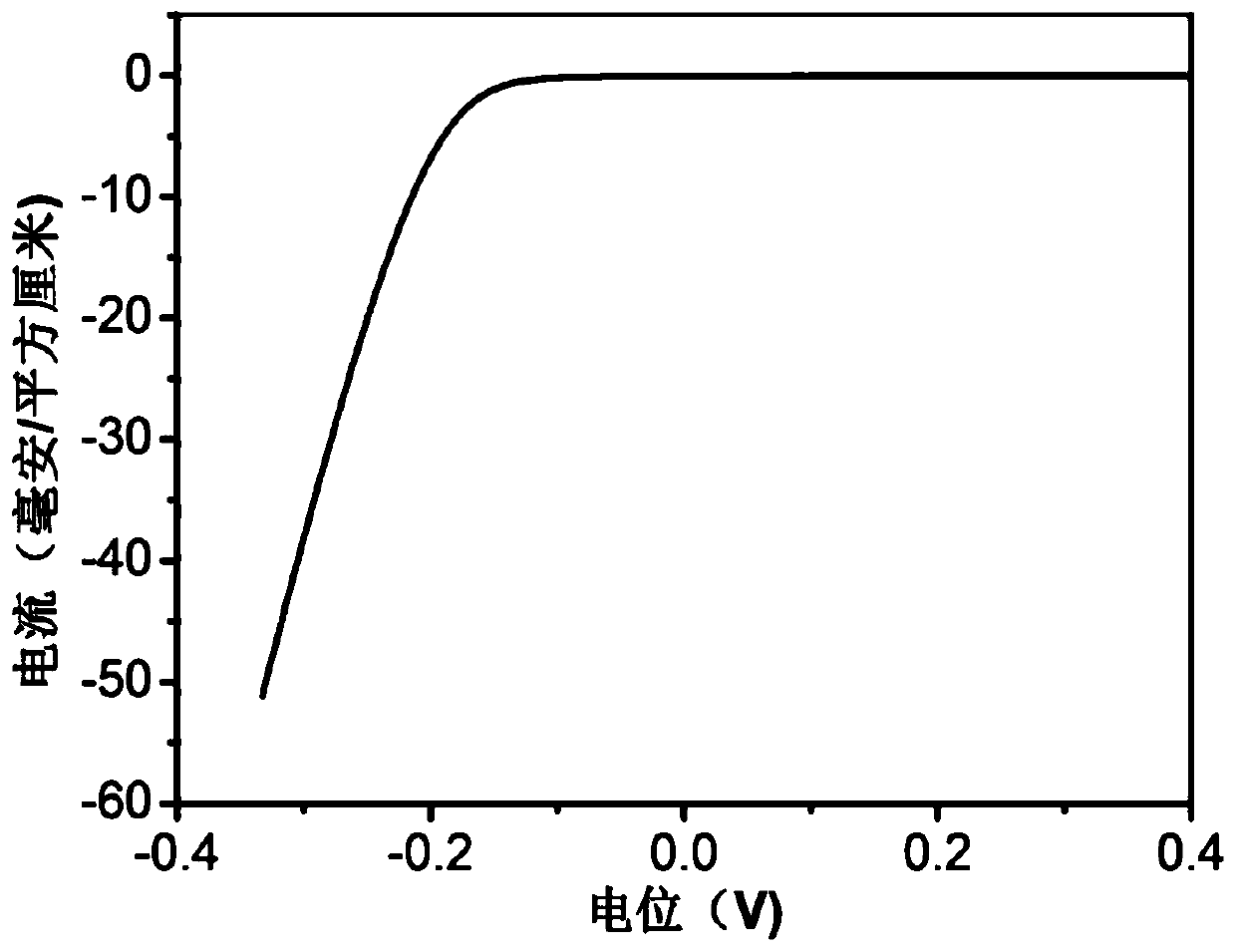

[0025] Such as figur...

Embodiment 2

[0028] Add 0.35 grams of sodium molybdate, 2 grams of thioacetamide, 0.7 grams of ammonium fluoride, and 45 ml of water into a stainless steel reaction kettle with a volume of 75 ml in sequence, stir for 30 minutes, seal, and the filling capacity is 60%; The kettle was placed in a crucible boiler, heated at 450°C for 12 hours, and then the reaction kettle was naturally cooled to room temperature, and the mixture was taken out. The above mixture was washed 3 times successively with absolute ethanol, 0.5 mol / liter of dilute hydrochloric acid and distilled water, filtered, and then placed in a vacuum drying oven with a vacuum degree of -1Mpa at 60 ° C for 24 hours to obtain Fluorine and nitrogen co-doped molybdenum disulfide with excellent catalytic activity for hydrogen production from water electrolysis.

[0029] Such as Figure 4 As shown, it can be seen that fluorine and nitrogen co-doped molybdenum disulfide have discontinuous lattices and disconnected lattices, which provi...

Embodiment 3

[0031] Add 0.35 gram of ammonium molybdate, 0.7 gram of thiourea, 0.7 gram of ammonium fluoroborate, and 45 ml of water into a stainless steel reactor with a volume of 75 ml, stir for 10 minutes, seal, and the filling capacity is 60%; then put the reactor into In a crucible boiler, heat at 350° C. for 12 hours, then allow the reaction kettle to cool down to room temperature naturally, and take out the mixture. The above mixture was washed 5 times successively with absolute ethanol, 0.5 mol / liter of dilute hydrochloric acid and distilled water, filtered, and then placed in a vacuum oven with a vacuum degree of -1Mpa and vacuum-dried at 70°C for 24 hours to obtain Fluorine and nitrogen co-doped molybdenum disulfide with excellent catalytic activity for hydrogen evolution in electrolysis of water.

[0032] Such as Figure 5 As shown, it can be seen that the molybdenum disulfide co-doped with fluorine and nitrogen has a microscopic mesoporous structure, which provides a fast ion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com