High-solid-content self-extinction waterborne polyurethane dispersion and preparation method thereof

A water-based polyurethane, high solid content technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor adhesion, easy to break and fall off, and the coating is brittle, so as to achieve low production, storage and transportation costs, The effect of fast drying and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

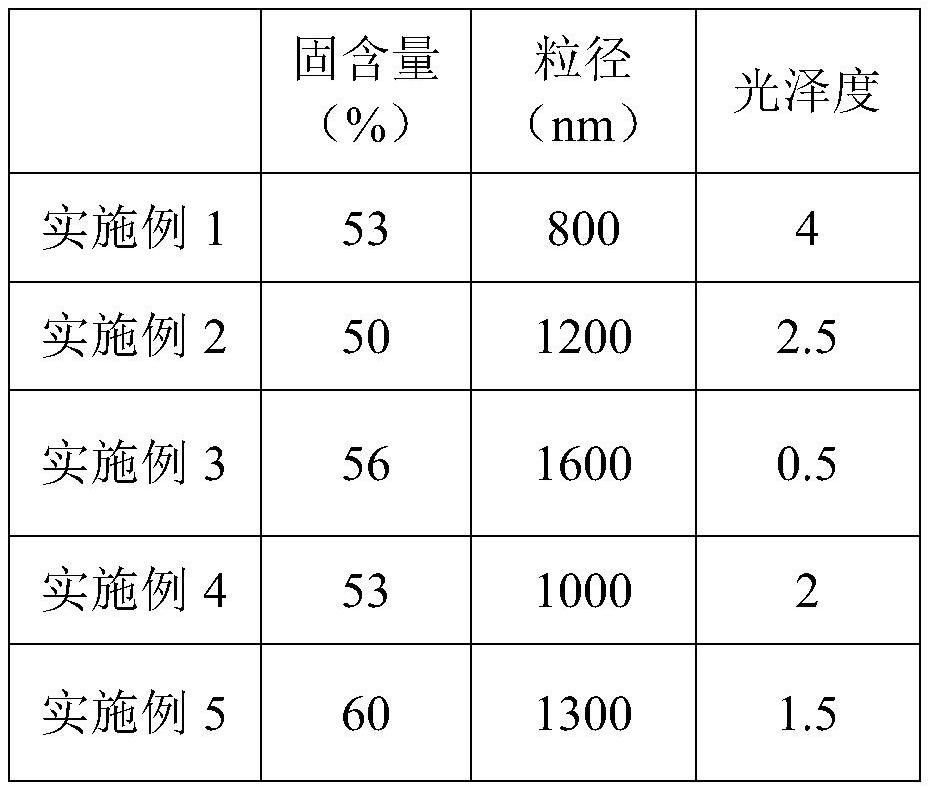

Examples

preparation example Construction

[0053] The second aspect of the present invention provides a kind of preparation method of high solid content self-delustering aqueous polyurethane dispersion, and specific preparation steps comprise:

[0054] S1. Add polymer polyol and isocyanate in the reactor, and react to generate the first prepolymer;

[0055] S2. Add a first chain extender, an organic solvent, and a catalyst to the first prepolymer, and react to obtain a second prepolymer;

[0056] S3. Transfer the second prepolymer to a high-speed emulsifier, add water, and stir to obtain the finished product;

[0057] The second chain extender is added in at least one step of S1, S2, and S3.

[0058] In some preferred embodiments, the reaction temperature of the S1 step is 60-95° C., and the reaction time is 1-3 h.

[0059] Further preferably, the reaction temperature of the S1 step is 90° C., and the reaction time is 2 hours.

[0060] In some preferred embodiments, the reaction temperature of the step S2 is 30-80°C...

Embodiment 1

[0069] This embodiment provides a high solid content self-dulling aqueous polyurethane dispersion. According to weight percentage, its raw materials include: polymer polyol 26%, isocyanate 16%, first chain extender 1%, second chain extender 1%, catalyst 0.1%, organic solvent 17%, water to make up the balance;

[0070] The first chain extender is 1,2-dihydroxy-propanesulfonic acid triethylamine salt, which comes from Xiamen Weiliang Optical Coating Technology Co., Ltd.

[0071] The polymer polyol is polybutylene adipate diol with an average molecular weight of 1000, purchased from Dongguan Suguang Plastic Raw Materials Co., Ltd.

[0072] The isocyanate is isophorone diisocyanate.

[0073] The second chain extender is a polyhydric alcohol, specifically trimethylolpropane.

[0074] The catalyst is an organic tin catalyst, specifically dibutyltin dilaurate.

[0075] The organic solvent is acetone with a boiling point of 56.3°C.

[0076] The preparation method of described high...

Embodiment 2

[0081] This embodiment provides a high solid content self-dulling aqueous polyurethane dispersion. According to weight percentage, its raw materials include: polymer polyol 21%, isocyanate 16%, first chain extender 1%, second chain extender 3.4%, catalyst 0.1%, organic solvent 18%, water to make up the balance;

[0082] The first chain extender is 1,2-dihydroxy-propanesulfonic acid triethylamine salt, which comes from Xiamen Weiliang Optical Coating Technology Co., Ltd.

[0083] The polymer polyol is polyoxypropylene triol with an average molecular weight of 3000, purchased from Chengdu Bright Chemical Technology Co., Ltd.

[0084] The isocyanate is isophorone diisocyanate.

[0085] The second chain extender is a polyol and a polyamine; the polyol is specifically dimethylol butyric acid and diethylene glycol, and the polyamine is specifically ethylenediamine; the dimethylol butyrate The weight ratio of acid, diethylene glycol and ethylenediamine is 1:2:0.4.

[0086] The cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com