Polydopamine film and application thereof, and method for preparing nonvolatile memristor and volatile memristor

A technology of polydopamine film and polydopamine, applied in the direction of nanotechnology, nanotechnology, electrical components, etc. for materials and surface science, can solve the problems of poor flatness, poor continuity of PDA, low thickness controllability, etc., and achieve uniformity Good performance and continuity, realize repeated storage, and facilitate the effect of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] (1) Preparation of Tris-HCl buffer solution: Tris was added into deionized water, and its pH value was adjusted with dilute hydrochloric acid to obtain Tris-HCl buffer solution;

[0044] (2) Preparation of dopamine solution: dissolving dopamine hydrochloride in the Tris-HCl buffer solution to obtain dopamine solution;

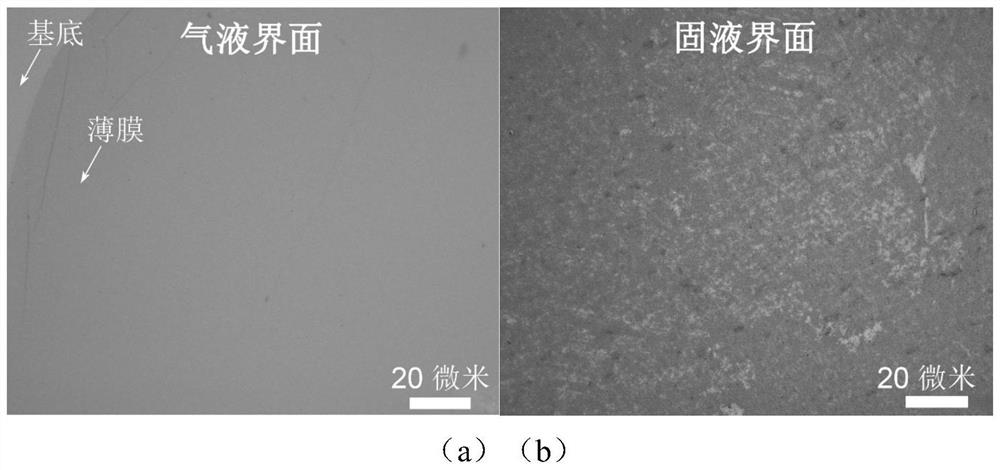

[0045] (3) Preparation of polydopamine film: the dopamine solution is left standing at room temperature, and the dopamine solution is in a sealed state, self-assembled on the gas-liquid interface on the surface of the dopamine solution to form a continuous and uniform large area visible to the naked eye The film is a polydopamine film; the generated polydopamine film is transferred to the substrate by LB film technology for standby;

[0046] (4) Repeated preparation of the polydopamine film: then continue to place the dopamine solution in an airtight container, and self-assemble again on the surface of the dopamine solution to form a new polydopamine fil...

preparation example 1

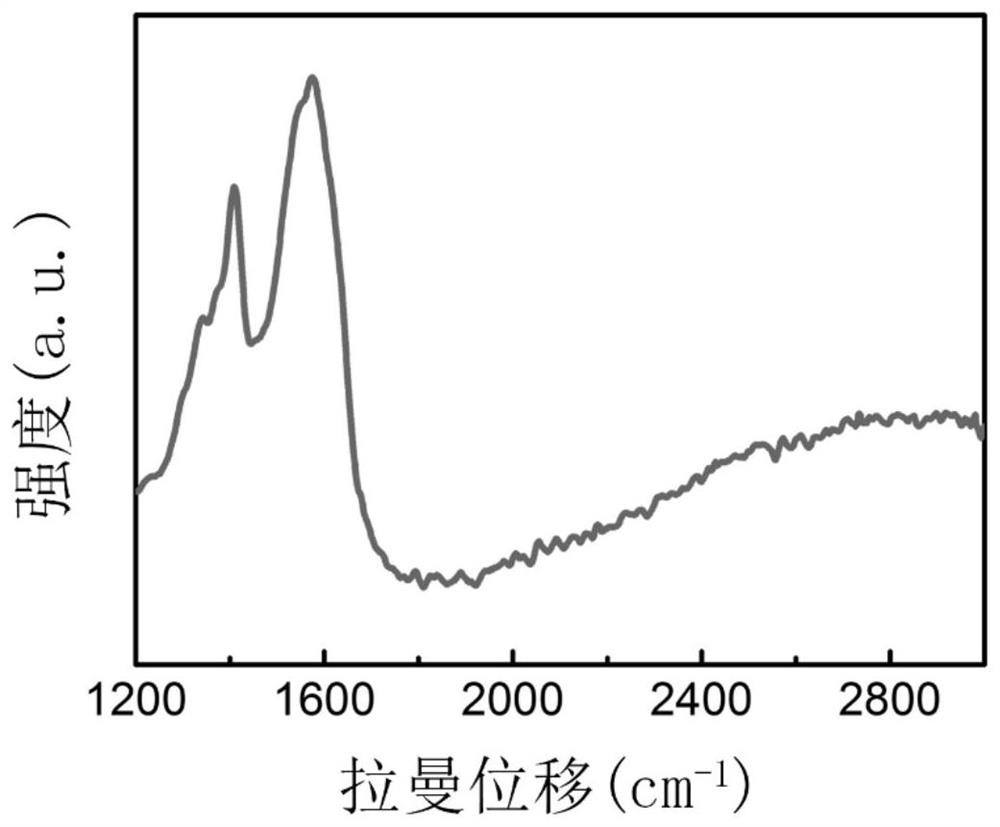

[0065] Preparation of polydopamine films:

[0066] (1) Preparation of Tris-HCl buffer solution: Tris was added to deionized water, and its pH value was adjusted to 8.77 with dilute hydrochloric acid to obtain a Tris-HCl buffer solution with a Tris concentration of 5 mM;

[0067] (2) Preparation of dopamine solution: dissolving dopamine hydrochloride in the Tris-HCl buffer solution to obtain a dopamine solution with a dopamine hydrochloride concentration of 0.4 mg / mL;

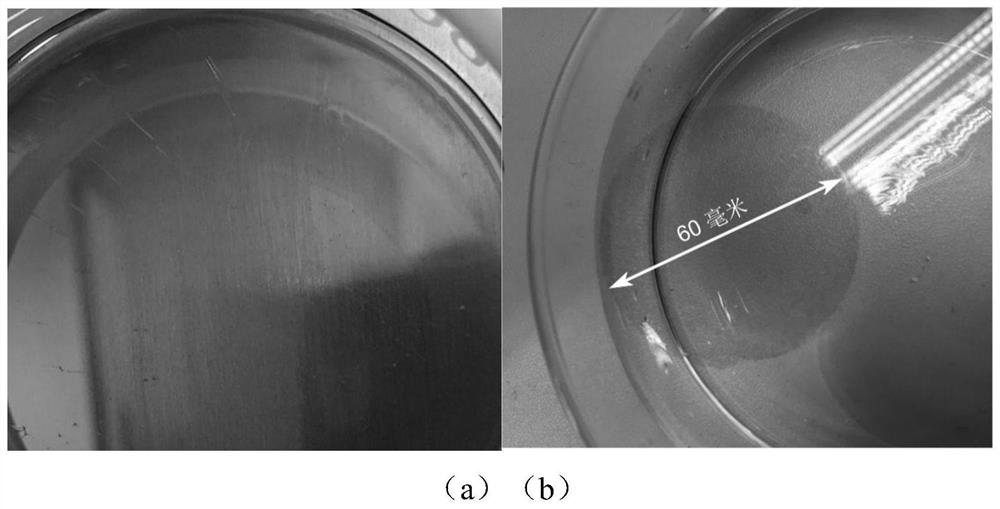

[0068] (3) Preparation of polydopamine film: under airtight conditions, the dopamine solution was left to stand at room temperature for 1.2 hours, and self-assembled on the gas-liquid interface on the surface of the dopamine solution to form a large-area uniform film visible to the naked eye, which is the polydopamine film. Dopamine film, adopting LB (langmuir-blogett) transfer method to transfer the polydopamine film that generates to the substrate for subsequent use;

[0069] (4) Repeated preparation of the p...

preparation example 2-5

[0093] The polydopamine film of this preparation example was prepared according to the method of preparation example 1, except that the corresponding parameters in the following table 1 were used instead of the parameters of preparation example 1, and the test results are shown in table 1.

[0094] Table 1

[0095]

[0096] As can be seen from Table 1, the present invention can regulate the thickness of the film by changing the standing time, because the method of the present invention makes the polymerization rate slow, even after self-assembly 6h the thickness of the polydopamine film is also less than 10nm. It can be known from Example 1 and Comparative Examples 1-2 that the polydopamine film prepared by the method of the present invention has a more controllable and smaller thickness and is smoother.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com