Method for preparing a microcircuit by printing liquid metal ink through commercial ink-jet printer and application thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for preparing a stable liquid metal ink and a microcircuit, the specific steps of the method are as follows:

[0048] (1) Preparation of liquid metal ink

[0049] Weigh 200mg of SDS into the reagent bottle, add 20g of deionized water, put it into the magnetic force to stir the plate for 30 minutes, take out the rotor, add 1g of gallium indium liquid metal (EGaIn), place it under the probe ultrasonic machine, set the ultrasonic program to ultrasonic 5s, pause for 5s, control temperature not to exceed 20°C, ultrasonic power 300W, ultrasonic for 15min and then stand for 12h, take the supernatant as liquid metal ink. Obtained liquid metal ink by standing for 1h and 1 day, observe its stability as attached figure 1 As shown, the particle size distribution of the prepared liquid metal ink is as attached figure 2 shown;

[0050] (2) Inkjet printing

[0051] Suck out the remaining ink in the commercial inkjet printer, pour it into the prepared liquid metal ink, de...

Embodiment 2

[0058] The preparation method of the PVP-coated liquid metal ink and microcircuit, the specific steps of the method are as follows:

[0059] (1) Preparation of liquid metal ink

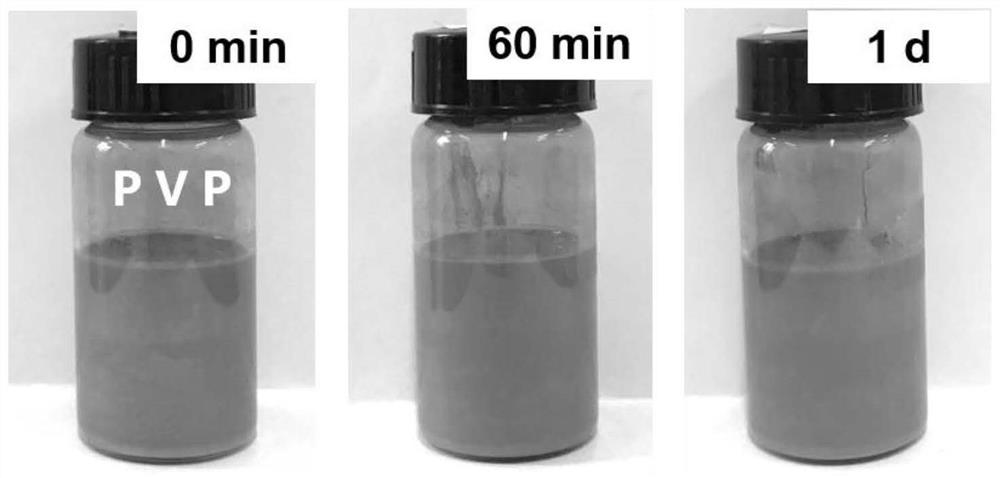

[0060] Weigh 200mg of PVP into the reagent bottle, add 20g of ethanol, put it into the magnetic force to stir the plate for 30 minutes, take out the rotor, add 1g of gallium indium liquid metal (EGaIn), place it under the probe ultrasonic machine, set the ultrasonic program for 5s, Pause for 5s, control the temperature not to exceed 20°C, and ultrasonic power to 450W. After ultrasonication for 30min, let stand for 12h, and take the supernatant as liquid metal ink. The TEM image of the liquid metal microsphere is attached Figure 4 shown;

[0061] (2) Inkjet printing

[0062] Suck out the remaining ink in the commercial inkjet printer, pour it into the prepared liquid metal ink, design the required pattern with a computer, cut the nylon filter membrane into A4 paper size, put it into the inkjet prin...

Embodiment 3

[0065] A method for preparing a high-concentration liquid metal ink and a microcircuit, the specific steps of the method are as follows:

[0066] (1) Preparation of liquid metal ink

[0067] Weigh 600mg of PVP into the reagent bottle, add 20g of ethylene glycol, put it into the magnetic force to stir the plate for 30 minutes, take out the rotor, add 3g of gallium indium liquid metal (EGaIn), place it under the probe ultrasonic machine, set the ultrasonic program to ultrasonic 5s, pause for 5s, control the temperature not to exceed 20°C, ultrasonic power is 600W, after 60min of ultrasonic, let stand for 12h, take the supernatant liquid as liquid metal ink;

[0068] (2) Inkjet printing

[0069] Suck out the remaining ink in the commercial inkjet printer, pour it into the prepared liquid metal ink, design the required pattern with a computer, cut the nylon filter membrane into A4 paper size, put it into the inkjet printer for inkjet printing, and print it Take it out, align and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com