Electrode slurry composition, pole piece and secondary battery thereof

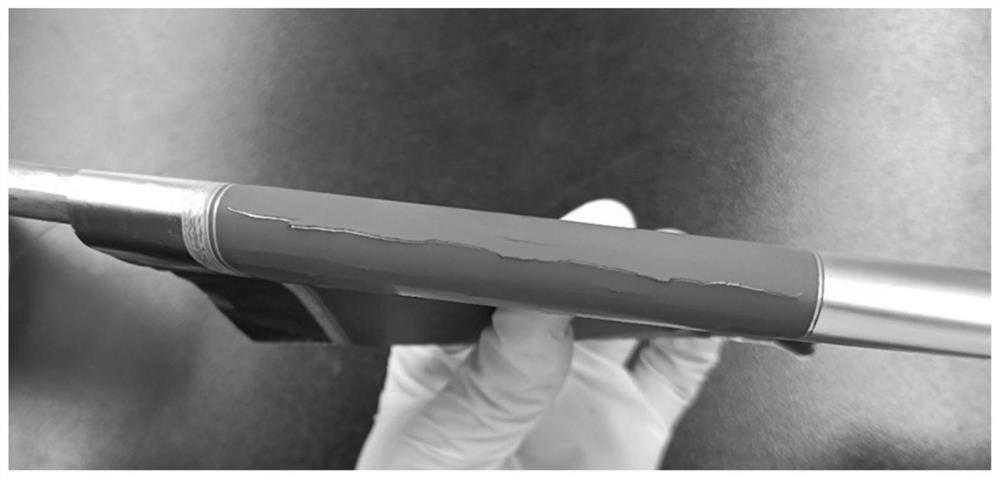

A technology of electrode slurry and electrode sheet, which is applied in the direction of secondary batteries, battery electrodes, circuits, etc., can solve the problems of insufficient flexibility, cracking and cracking of thick electrode sheets with high surface density, and achieve good slurry stability and Effects of dispersibility, improvement of flexibility, and increase of coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

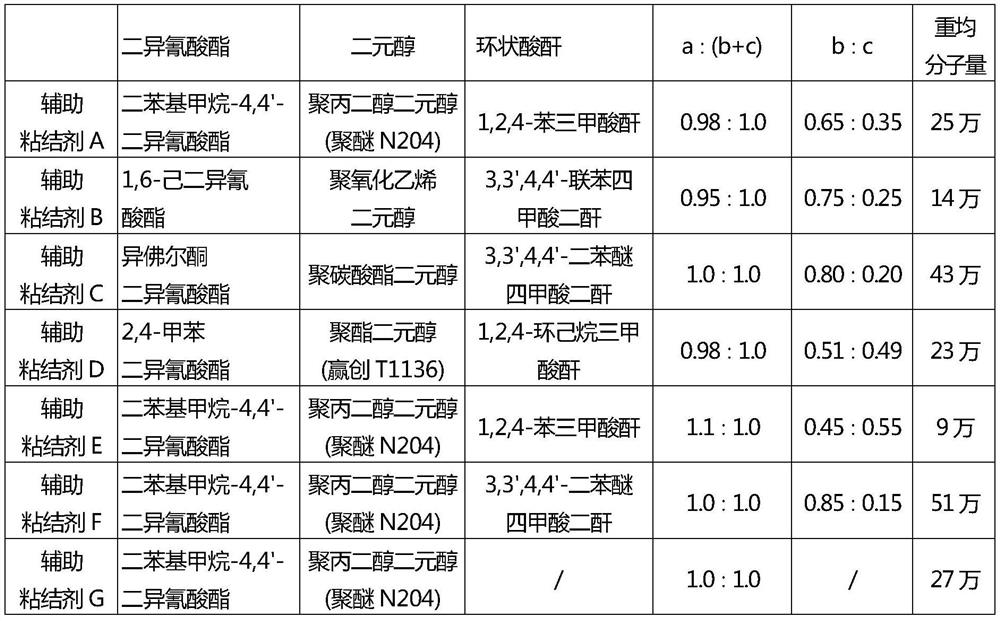

[0065] Add 0.65mol of polypropylene glycol diol (polyether N204) into a 500mL flask equipped with a thermometer and a mechanical stirrer, stir and dehydrate at 105°C for 1h under vacuum, after cooling down to 80°C, add 0.98mol of diphenyl Methane-4,4'-diisocyanate was incubated at 80°C for 1h. Next, when the temperature of the system drops below 50°C, add 0.35 mol of 1,2,4-benzenetricarboxylic anhydride, stir rapidly for 10 minutes, control the reaction temperature not to exceed 90°C, then pour the reaction liquid into the mold, at 120°C After curing for 6 hours, the auxiliary binder A of the present invention is obtained. The weight average molecular weight of the auxiliary binder A is 250,000 through gel permeation chromatography test. See Table 1 for specific components and reaction molar ratios.

[0066]

[0067]The preparation steps are basically the same as the preparation example of auxiliary binder A, the difference lies in the reaction components and their reactio...

Embodiment 1

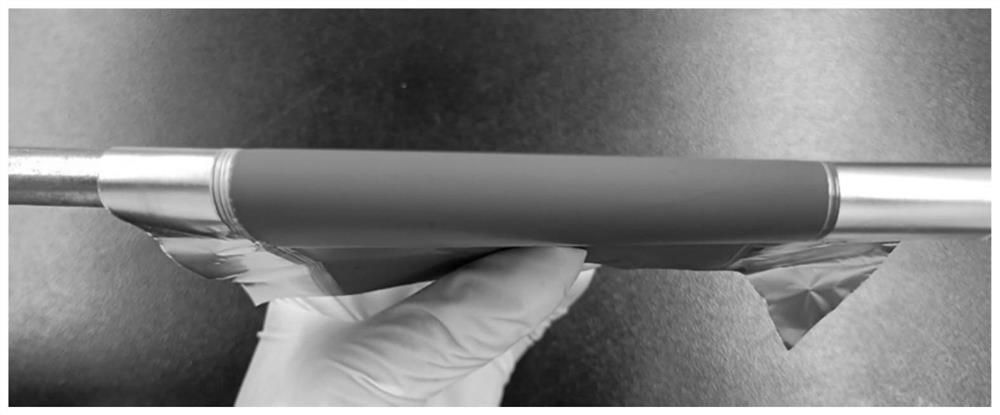

[0081] In parts by mass, 93.0 parts of lithium iron phosphate (Betterui, P198-S13), 2.0 parts of carbon nanotubes (Cabot, GCNTs5), 4.0 parts of polyvinylidene fluoride (Solvay, PVDF5130) and 110.0 parts Add N-methylpyrrolidone to the homogenizer, mix at 600r / min for 1min at 25°C, and then add 0.5 parts of auxiliary binder A, 0.5 parts of dispersing aid (fluorocarbon surfactant FS-300) and 1.0 parts of N-methylpyrrolidone mixed glue, mixed at 1000r / min for 10min to form electrode slurry, and then coated with a scraper at a coating speed of 30m / min, the electrode The slurry is evenly coated on the front and back surfaces of aluminum foil with a thickness of 16 μm, baked and dried at 105° C. for 1 hour, and after removing the solvent, the aluminum foil in Example 1 of the present invention has an areal density of 260 g / m on the front and back surfaces of the aluminum foil. m 2 The electrode sheet of the electrode film layer.

Embodiment 2~15

[0083] The basic preparation steps of the electrode slurry composition are the same as in Example 1, except for the components and contents of the electrode slurry composition, as shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com