Microorganism soil layer dispersion mixed inoculation method

A soil layer and microbial technology, applied in the field of soil remediation, can solve the problems of long duration of microbial remediation and low remediation efficiency, and achieve the effect of easy in-situ repair, convenient operation and improved removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0089] According to a preferred embodiment of the present invention, the fungus is an AM fungus (arbuscular mycorrhizal fungus), preferably selected from one or more of Glomus mosei, Glomus intraradices, and Glomus tertiformis .

[0090] Among them, AM fungi are a class of ubiquitous soil fungi that can form symbionts with some terrestrial plants.

[0091] In a further preferred embodiment, the fungus is Glomus moesei and / or Glomus intraradices, preferably Glomus moesei and Glomus intraradices;

[0092] Preferably, the weight ratio of Glomus mosei and Glomus intrarhizoi is (1-3):1, preferably (1.5-2.5):1.

[0093] The inventors of the present invention have found that inoculating the above-mentioned types and ratios of fungal agents in the soil is beneficial to work together with plants to efficiently restore heavy metal-contaminated soil.

[0094] Wherein, the AM fungus can be obtained commercially, or can be obtained by self-cultivation by conventional cultivation methods....

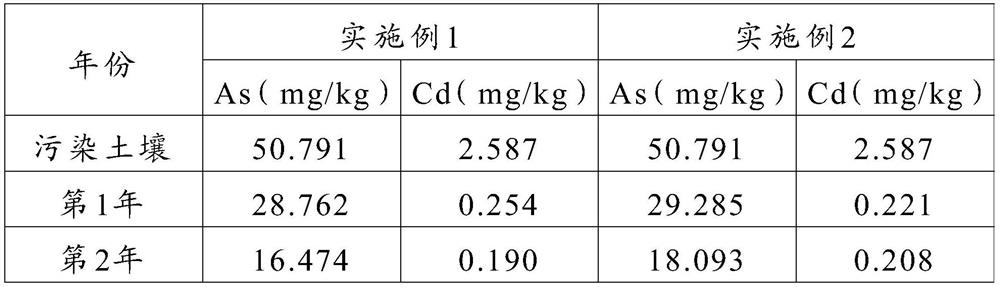

Embodiment 1

[0114] Follow the steps below to remediate cadmium and arsenic contaminated soil:

[0115] (1) Plow the soil to be repaired, maintain it for 30 days under natural conditions, and then apply a soil improver according to the weight ratio of the soil improver to the soil at 7:100. The soil improver is based on iron-rich biochar, kaolin and humic acid The weight ratio of phytic acid is obtained by mixing 20:30:35;

[0116] Wherein, iron-rich biochar is prepared according to the following steps:

[0117] Cultivate cattails in red soil areas, add vermicompost according to the volume ratio of vermicompost and cultivation soil as 55:100 during the cultivation process; pull out the whole cattail plant when harvesting, wash with deionized water, soak in 0.01M dilute hydrochloric acid for 1 hours, dried and pulverized at 70.0°C; in a tubular muffle furnace, heated up to 685°C at a heating rate of 4°C / min for pyrolysis, kept for 75min, and then cooled to room temperature to obtain iron-r...

Embodiment 2

[0125] Follow the steps below to remediate cadmium and arsenic contaminated soil:

[0126] (1) Plow the soil to be repaired, maintain it for 30 days under natural conditions, and then apply a soil improver according to the weight ratio of the soil improver and soil at 4:100. The soil improver is based on iron-rich biochar, kaolin and humic acid The weight ratio of phytic acid is obtained by mixing 20:35:40;

[0127] Wherein, iron-rich biochar is prepared according to the following steps:

[0128] Cultivate cattail in red soil area, add vermicompost according to the volume ratio of vermicompost and cultivation soil in the cultivation process as 60:100; pull out the whole cattail plant when harvesting, wash with deionized water, soak in 0.01M dilute hydrochloric acid for 1 hours, dried and pulverized at 70.0°C; in a tubular muffle furnace, heated up to 715°C at a heating rate of 3°C / min for pyrolysis, kept for 65 minutes, and then cooled to room temperature to obtain iron-rich ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com