Preparation method of large-diameter hydrogen embrittlement prevention titanium alloy spring

A titanium alloy spring and large-diameter technology, which is applied in the direction of manufacturing springs from wires, manufacturing tools, and heat treatment equipment, can solve problems such as unsatisfactory corrosion resistance of titanium alloys, avoid hydrogen embrittlement, improve surface quality, Effect of improving lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

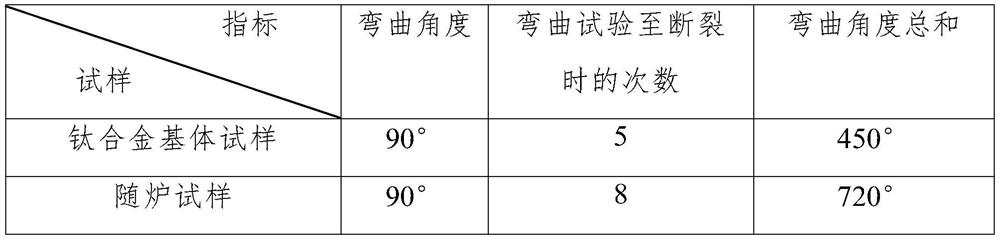

Examples

Embodiment 1

[0031] This embodiment includes the following steps:

[0032] Step 1. Forging TB9 titanium alloy by free forging process, and the temperature used for forging is 1100°C, the holding time is 3h, and then rolling at 800°C for 120min to obtain a hot-rolled titanium alloy billet; the TB9 titanium alloy is made of The composition of the following mass content: Al 3.0%, V 8.5%, Cr 5.5%, Zr 4.5%, Mo 3.5%, Pd 0.1%, the total mass content of impurities including Fe, C, N, H, O is 1.05%, The balance is Ti;

[0033] Step 2, performing solution treatment on the hot-rolled titanium alloy billet obtained in step 1 at 890° C. for 30 minutes, and then peeling and polishing to obtain a titanium alloy wire with a diameter of 5 mm;

[0034] Step 3, coiling the titanium alloy wire obtained in step 2, then performing an aging treatment at 480° C. for 12 hours, and then performing a shot blasting treatment to obtain a titanium alloy spring wire;

[0035] Step 4. Put the titanium alloy spring wire o...

Embodiment 2

[0042] This embodiment includes the following steps:

[0043] Step 1. Forging TB9 titanium alloy by free forging process, and the temperature used for forging is 1150°C, the holding time is 1.5h, and then rolling at 880°C for 90 minutes to obtain a hot-rolled titanium alloy billet; the TB9 titanium alloy It is composed of the following components by mass content: Al 4.0%, V 7.5%, Cr 6.5%, Zr 3.5%, Mo 4.5%, Pd 0.08%, and the total mass content of impurities including Fe, C, N, H, O is 1.05% , the balance is Ti;

[0044] Step 2, performing solution treatment on the hot-rolled titanium alloy billet obtained in step 1 at 900° C. for 30 minutes, and then peeling and polishing to obtain a titanium alloy wire with a diameter of 25 mm;

[0045] Step 3, coiling the titanium alloy wire obtained in step 2, then performing an aging treatment at 520° C. for 8 hours, and then performing a shot blasting treatment to obtain a titanium alloy spring wire;

[0046] Step 4. Put the titanium all...

Embodiment 3

[0053] This embodiment includes the following steps:

[0054] Step 1. Forging TB9 titanium alloy by free forging process, and the temperature used for forging is 1130° C., the holding time is 2 hours, and then rolling at 930° C. for 120 minutes to obtain a hot-rolled titanium alloy billet; the TB9 titanium alloy is made of The composition of the following mass content: Al 3.0%, V 8.5%, Cr 6.5%, Zr 3.5%, Mo 4.5%, Pd 0.1%, the total mass content of impurities including Fe, C, N, H, O is 1%, The balance is Ti;

[0055] Step 2. The hot-rolled titanium alloy billet obtained in step 1 is subjected to solution treatment at 970°C for 30 minutes, and then peeled and polished to obtain a titanium alloy wire with a diameter of 13.1 mm;

[0056] Step 3, coiling the titanium alloy wire obtained in step 2, then performing an aging treatment at 560° C. for 4 hours, and then performing a shot blasting treatment to obtain a titanium alloy spring wire;

[0057] Step 4. Put the titanium alloy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com