Polyvinyl chloride paste resin and preparation method thereof

A technology of polyvinyl chloride paste resin and polyvinyl chloride paste, which is applied in the field of polyvinyl chloride paste resin and its preparation, can solve the problems of poor degassing performance of paste resin, many pinholes in produced products, and increased processing costs, and achieve degassing Good foam performance, high mechanical strength, fast plasticizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

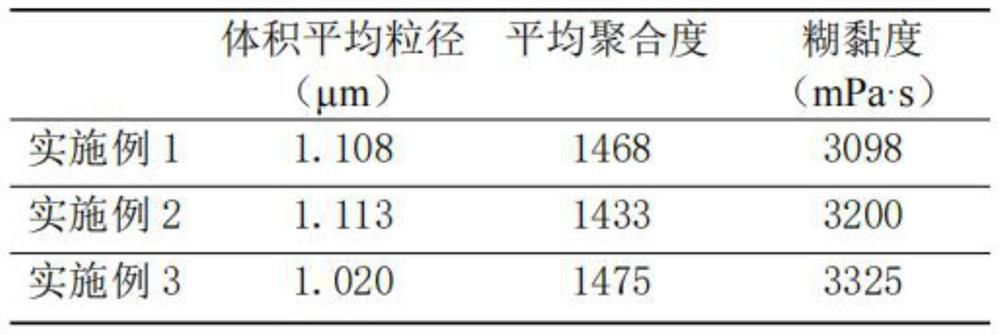

Examples

Embodiment 1

[0028] PVC paste resin and one kind of preparation, a polyvinyl chloride paste resin composition is as follows: PVC 99.0-99.022%, 0.7-0.734% sodium lauryl sulfate, sodium metabisulfite 0.093-0.0938%, water 0.1 to 0.15 %, potassium persulfate, cupric chloride, ammonium bicarbonate, and a mixture of mercaptoethanol 0.000002-0.107%.

Embodiment 2

[0030] Polyvinyl chloride paste resin prepared as follows:

[0031] S1: Preparation of seed: added in the polymerization vessel desalinated water, desalted water to 100 mass: 0.0084 potassium persulfate, sodium metabisulfite and 0.092 PH regulator NH 3 -NH 4 HCO 3 Buffer solution was adjusted PH, PH value is adjusted to 7.8-8.4, stir;

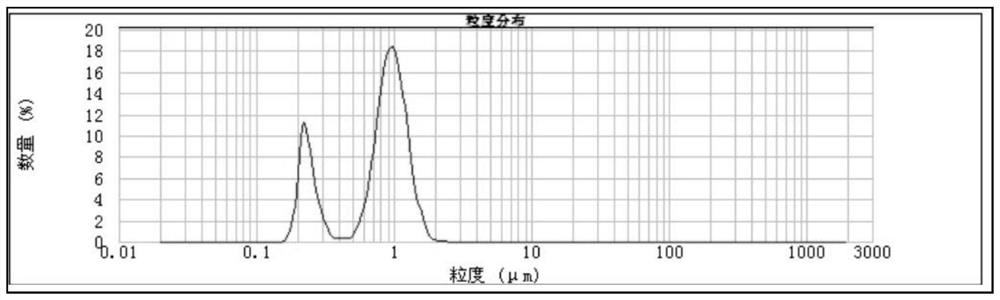

[0032] The polymerization kettle was added under vacuum initiator 0.092-0.109 sodium metabisulphite solution, the autoclave to control the speed of stirring, the vinyl chloride monomer and the emulsifier sodium lauryl sulfate solution is added continuously uniform, the reaction is stopped after a certain time of vinyl chloride monomer at 45 ℃ after stirring for 1h stop body and the emulsifier sodium lauryl sulfate solution reaction, the whole reaction was continued for 7-10h, desalinated water ratio of vinyl chloride 1.1-1.3: 1; mass ratio of vinyl chloride with 148-150 emulsifier: 1, the product produced in the size range 0.2-0.65 microns vinyl po...

Embodiment 3

[0038] The first step: Preparation of seed

[0039] In a volume of 1 square polymerization vessel was added 525 kg of desalinated water, copper chloride, sodium lauryl sulfate solid trace, and 0.042kg of potassium persulfate PH adjusting agents, PH adjusted to 7.8, mix well;

[0040] The polymerization kettle was added under vacuum the initiator 0.46kg sodium metabisulfite solution, controlling the stirring speed in the autoclave, and the emulsifier-containing vinyl chloride monomer 390.5kg 2.75kg sodium lauryl sulfate solution was added to 24L uniform continuous reaction at 45 ℃ 5h stop sodium lauryl sulfate solution, then the reaction was stirred for 1h vinyl chloride monomer was stopped after 1h was added to stop the reaction, the whole reaction was continued for 7h.

[0041] Second step: Polymerization

[0042] In a volume of 1 square polymerization vessel was added 525 kg demineralized water, a solution of copper chloride, potassium persulfate 0.046kg, sodium lauryl sulfate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com