P/N/Si multi-element synergistic integrated nano flame retardant as well as preparation method and application thereof

A nano-flame retardant and multi-component technology, applied in the field of flame retardant, can solve the problems that it is difficult to meet the development requirements of green chemistry, the toxicity and oxidation of raw materials are strong, and the flame retardant efficiency is barely improved, so as to suppress the release of toxic fumes, The effect of reducing the possibility and improving the flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

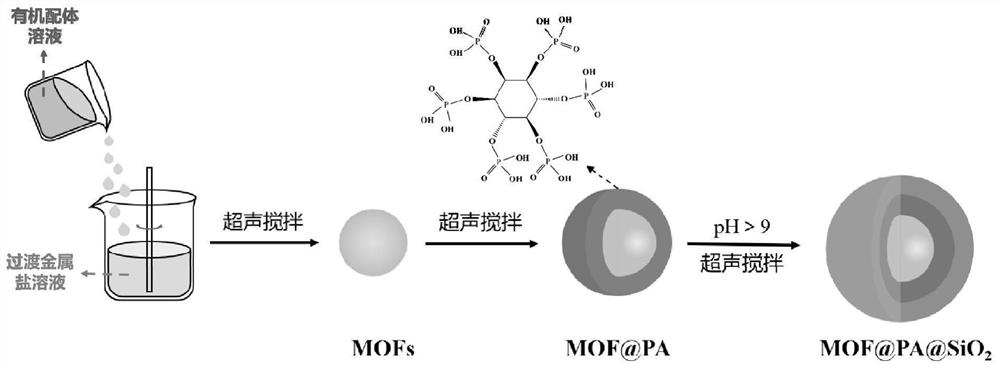

[0032] Such as figure 1 Shown, a kind of P / N / Si multiple synergistic integrated nano-flame retardant and preparation method thereof, comprises the following steps:

[0033] (1) Dissolve an appropriate amount of transition metal salt compound in an appropriate amount of methanol, and stir evenly;

[0034] (2) Dissolve an appropriate amount of 2-methylimidazole in an appropriate amount of methanol, dropwise add it to the solution in step (1), and after ultrasonic stirring, centrifuge to obtain the product, wash it with a solvent for 2 to 5 times, and then wash it at 50 to 80 Dry in an oven at ℃ for 3-10 hours to obtain MOF;

[0035] (3) Take an appropriate amount of MOF powder and disperse it in methanol. After forming a uniform suspension, add a certain amount of phytic acid dropwise, and stir the reaction at room temperature. After the reaction, the product is obtained by centrifugation, washed 2 to 5 times with solvent, and Dry in an oven at 50-80°C for 3-10 hours to obtain...

Embodiment 1

[0040] (1) Take 5.6g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 25mL of methanol, and stirred evenly;

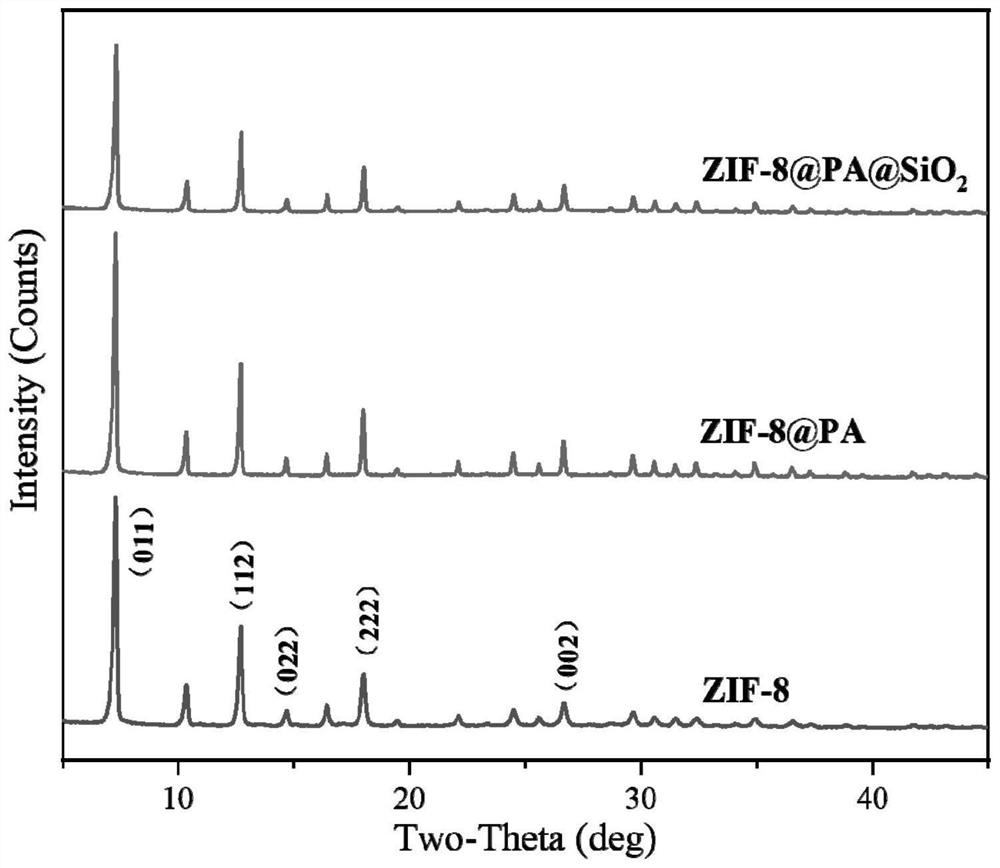

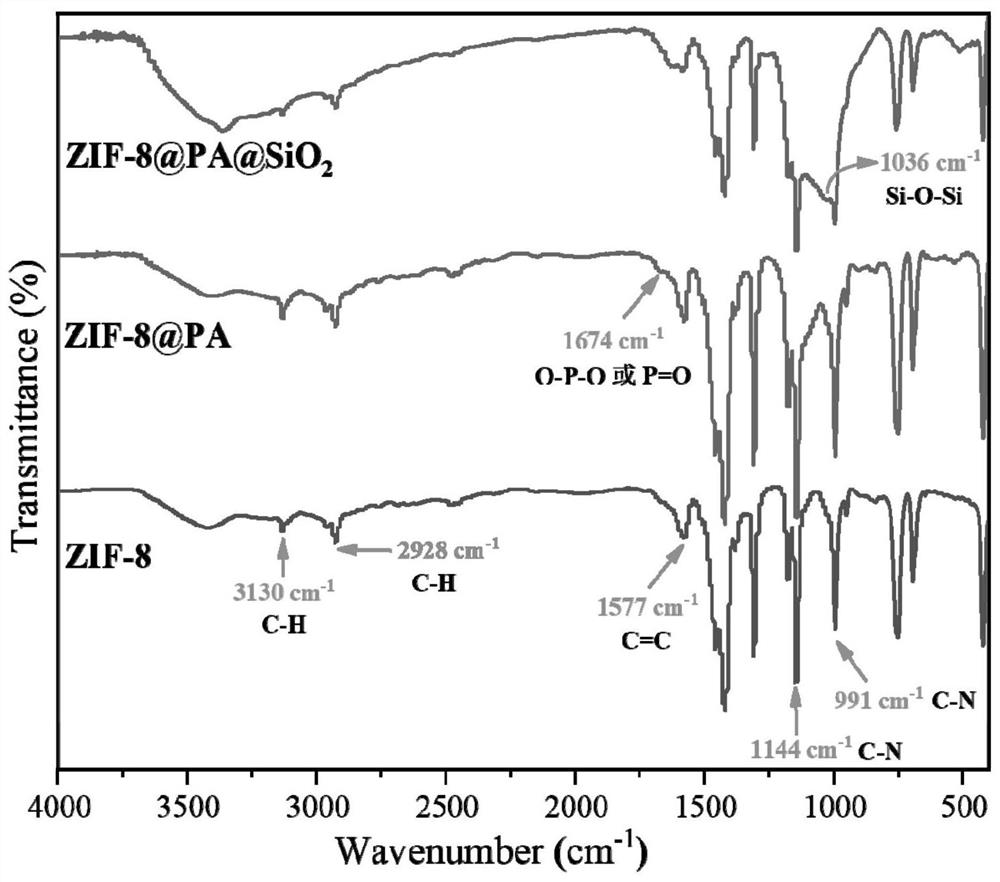

[0041] (2) Dissolve 12.0g of 2-methylimidazole in 25mL of methanol, add dropwise to the solution in step (1), and after ultrasonic stirring for 12 hours, centrifuge to obtain the product, wash it with solvent for 3 times, and then place it in an oven at 80°C Dry for 10h to obtain ZIF-8;

[0042] (3) Get 0.5g ZIF-8 powder and disperse it in 25mL methanol, after forming a uniform suspension, add 5mL of 0.5wt% phytic acid dropwise, and stir and react at room temperature for 12h. Wash with solvent for 3 times, and then dry in an oven at 80°C for 10 hours to obtain ZIF-8@PA;

[0043](4) Take 0.625g CTAB and disperse it in 30mL ethanol, and stir it ultrasonically for 30min;

[0044] (5) Add 0.5g ZIF-8@PA to the solution in step (4), and ultrasonically form a uniform suspension;

[0045] (6) Take 0.25g TEOS and dilute it in 25mL ethanol, then add it dropwise to the mixed solution i...

Embodiment 2

[0047] (1) Take 6.4g Co(NO 3 ) 2 ·6H 2 O was dissolved in 25mL of methanol, and stirred evenly;

[0048] (2) Dissolve 8.9g of 2-methylimidazole in 25mL of methanol, add it dropwise to the solution in step (1), and after ultrasonic stirring for 12 hours, centrifuge to obtain the product, wash it with a solvent for 3 times, and then place it in an oven at 80°C Dry for 10h to obtain ZIF-67;

[0049] (3) Get 1.0g ZIF-67 powder and disperse it in 25mL methanol, after forming a uniform suspension, add 20mL of 0.5wt% phytic acid dropwise, and stir and react at room temperature for 12h. Wash with solvent for 3 times, and then dry in an oven at 80°C for 10 hours to obtain ZIF-67@PA;

[0050] (4) Take 0.5g CTAB and disperse it in 30mL ethanol, and stir it ultrasonically for 30min;

[0051] (5) Add 0.6g ZIF-67@PA to the solution in step (4), and ultrasonically form a uniform suspension;

[0052] (6) Dilute 0.1 g of TEOS in 25 mL of ethanol, then dropwise add it to the mixed solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com