Zinc-aluminum-magnesium coating passivating agent, passivating film and passivating plate

A zinc-aluminum-magnesium and passivating agent technology, applied in coating, hot-dip plating process, metal material coating process, etc., can solve problems such as blackening and inability to meet welding purposes, and achieve poor flexibility and improve welding performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

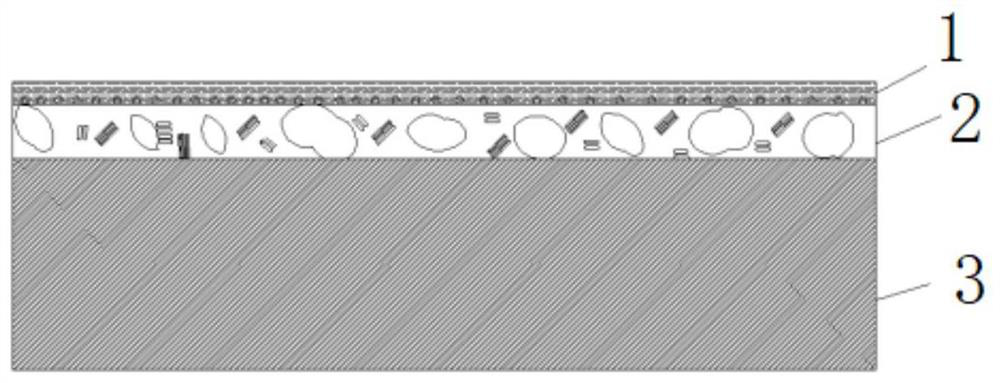

[0039] The zinc-aluminum-magnesium coating passivator of the present embodiment comprises the following components by weight: 10-20% inorganic salt, 2-5% hydrogen peroxide, 5-10% modified nano-zirconia sol, 1-3% phosphoric acid , 0.5-1% hydrofluoric acid and the balance of deionized water. The passivation agent of this solution is mainly an inorganic salt system, which can significantly improve the welding performance of the passivation plate. At the same time, adding modified nano-zirconia sol can improve the poor flexibility of the inorganic passivation film after the passivation agent is formed. When the content of inorganic salt in the passivation solution is small, it cannot play the role of passivation and corrosion resistance. When the content is large, it is difficult to form a film synergistically with other components. Therefore, the addition of inorganic salt is controlled at 10-20% in this plan. Hydrogen peroxide is a film-forming accelerator, which is beneficial t...

Embodiment 5

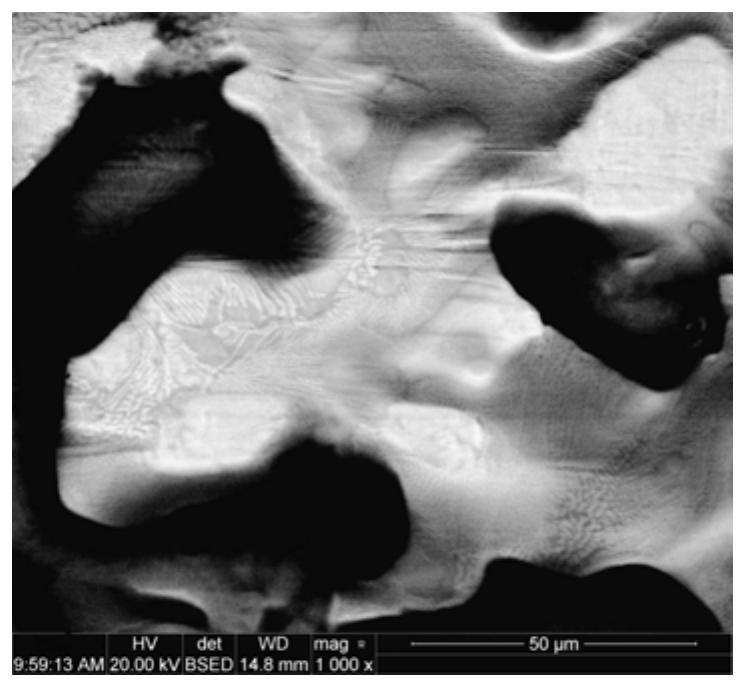

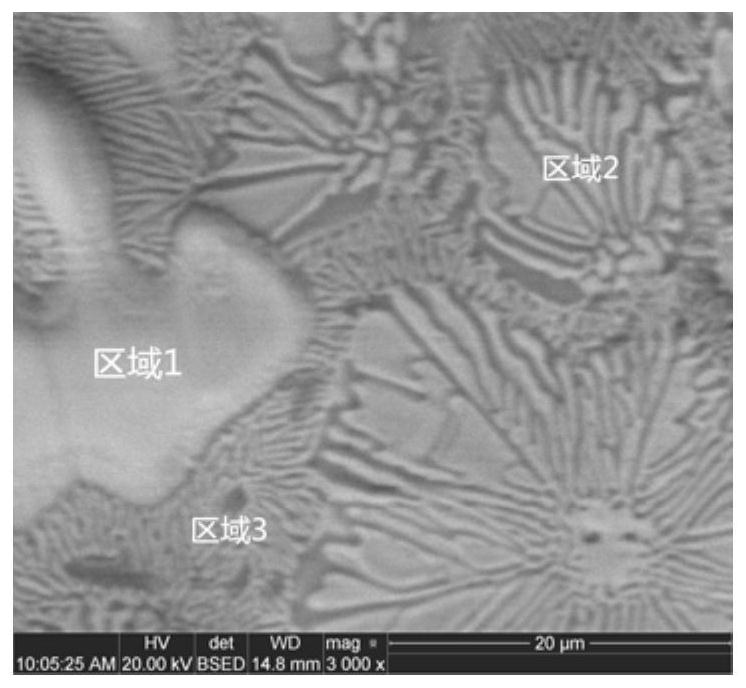

[0057] The surface microstructure of embodiment 5 is as figure 2 , 3 As shown, the passivating agent is enriched at the trough of the smooth surface (black area), the white phase of the coating structure area 1 is the Zn-rich phase, and the area 2 is Zn-MgZn 2 Binary eutectic phase (white phase) + aluminum-rich phase (black phase), zone 3 is Zn-Al-MgZn 2 In the ternary eutectic phase, the lamellar spacing of the ternary eutectic phase is smaller than that of the binary eutectic phase, both of which are less than 1 μm.

[0058] The comparative tests of the embodiments of the present invention and comparative examples are corrosion resistance test, blackening resistance test and welding test. The specific test and evaluation methods are as follows:

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| film density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com