Salt-spray-corrosion-resistant parallel seam welding alloy cover plate and preparation method thereof

A technology of parallel seam welding and salt spray resistance, which is applied in metal material coating process, semiconductor/solid-state device manufacturing, superimposed layer plating, etc., which can solve problems such as circuit reliability hidden dangers and exposed substrates, and achieve good Anti-salt spray corrosion performance, ensure integrity, enhance the effect of salt spray corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

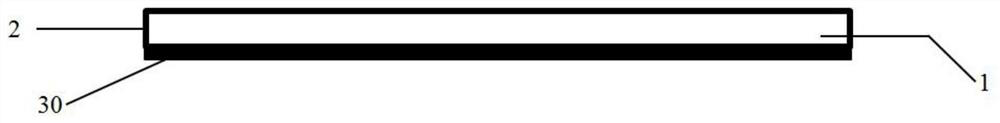

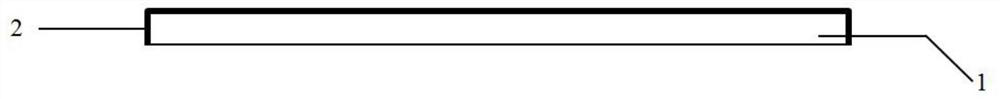

[0030] Such as Figure 4 As shown, a salt spray corrosion-resistant parallel seam welding alloy cover plate includes an alloy cover plate body 1, a diamond layer 2 is provided on the side and upper surface of the alloy cover plate body 1, and a diamond layer 2 is provided on the lower surface of the alloy cover plate body 1. The outer wrap is covered with a first protective layer 3 .

[0031] The thickness of the diamond layer is 0.1 μm to 15 μm.

[0032] The first protective layer 3 is a nickel layer, and the thickness of the nickel layer is 2 μm˜8.89 μm. The nickel in the nickel layer is a nickel-phosphorus alloy with a melting point of 880°C. The weight ratio of phosphorus in nickel-phosphorus alloy is 8%~12%.

[0033] Generally speaking, the parallel seam welding process will inevitably damage the cover plate body and coating, and the damage can only be controlled through process improvement, but cannot solve the problem of damage to the cover plate body and coating fro...

Embodiment 2

[0035] A salt spray corrosion-resistant parallel seam welding alloy cover plate, comprising an alloy cover plate body 1, a diamond layer 2 is provided on the side and upper surface of the alloy cover plate body 1, and the lower surface of the alloy cover plate body 1 and the diamond layer 2 are wrapped with The first protective layer 3 also includes a second protective layer wrapped on the first protective layer, the second protective layer is a gold-plated layer, and the first protective layer is a nickel layer.

[0036] The thickness of the gold-plated layer is 0.01-6 μm. The nickel in the nickel layer is high-purity nickel with a melting point of 1455°C, and the gold in the gold-plated layer is pure gold with a melting point of 1064°C.

Embodiment 3

[0038] Such as Figure 1 to Figure 4 Shown, a kind of preparation method of salt spray corrosion resistant parallel seam welding alloy cover plate comprises the following steps:

[0039] S10: The alloy cover body 1 is obtained by machining;

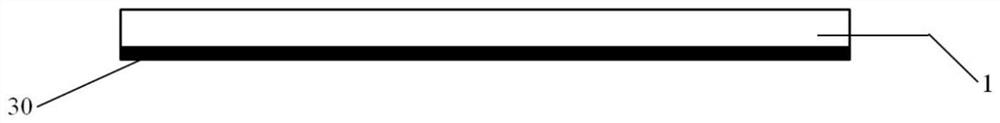

[0040] S20: After the alloy cover body 1 is cleaned, coat the isolation layer 30 on the lower surface, and dry the isolation layer 30;

[0041] S30: coating the upper surface and side surfaces of the alloy cover plate body 1 with diamond to form a diamond layer;

[0042] S40: removing the isolation layer 30, washing and drying;

[0043] S50: performing nickel plating on the alloy cover body 1 to obtain a first protective layer 3;

[0044] S60: After cleaning and drying, the production of the parallel seam welding alloy cover plate is completed.

[0045] The above method obtains a salt spray corrosion resistant parallel seam welded alloy cover plate of the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com