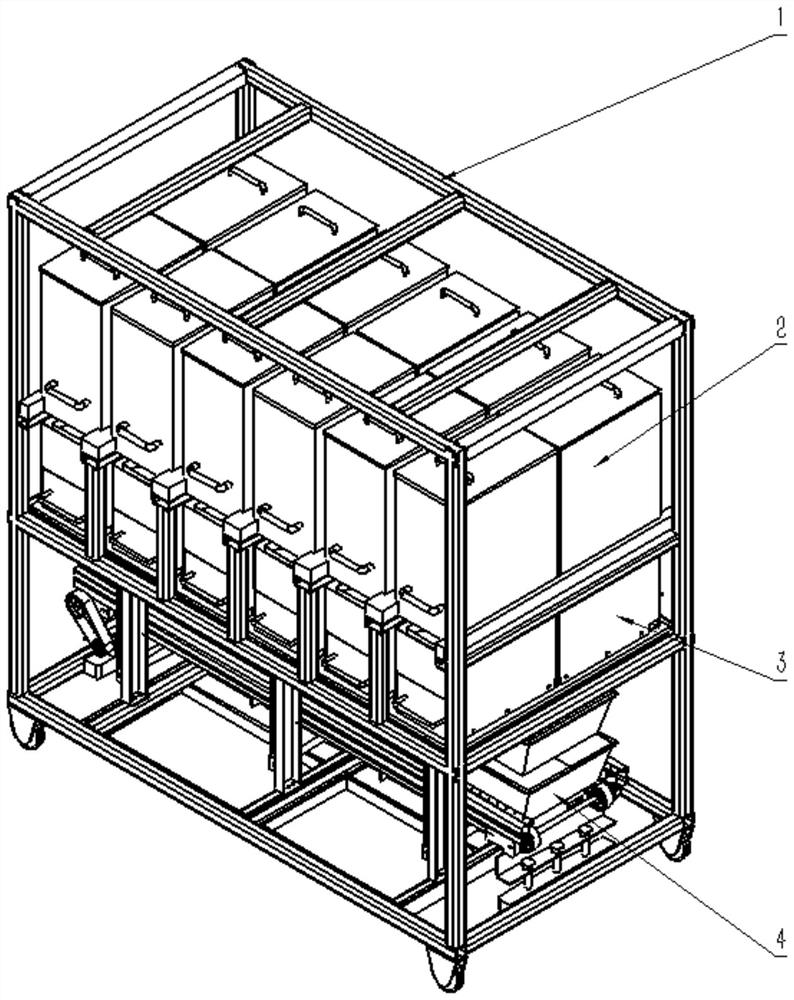

Intelligent dispensing system and method for raw material mixing

An intelligent, raw material technology, applied in mixers, chemical instruments and methods, solid materials, etc., can solve the problems of low mixing efficiency of raw materials and high labor costs, and achieve the effects of reducing labor costs, improving efficiency, and avoiding cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

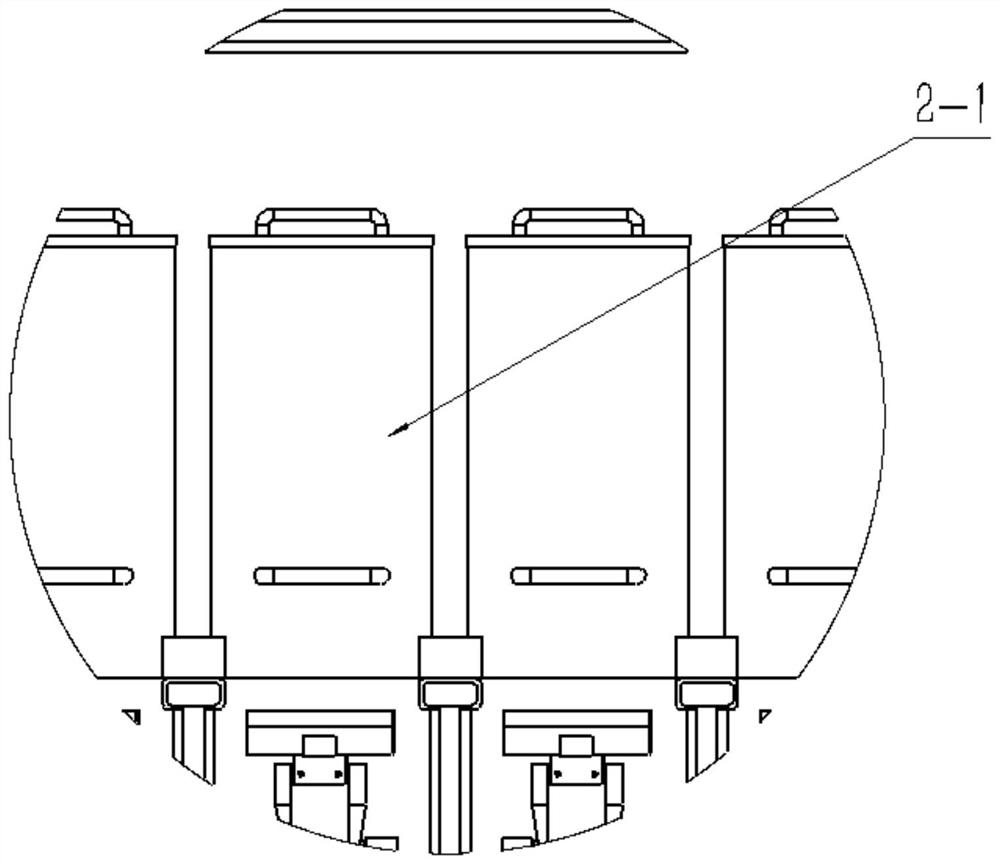

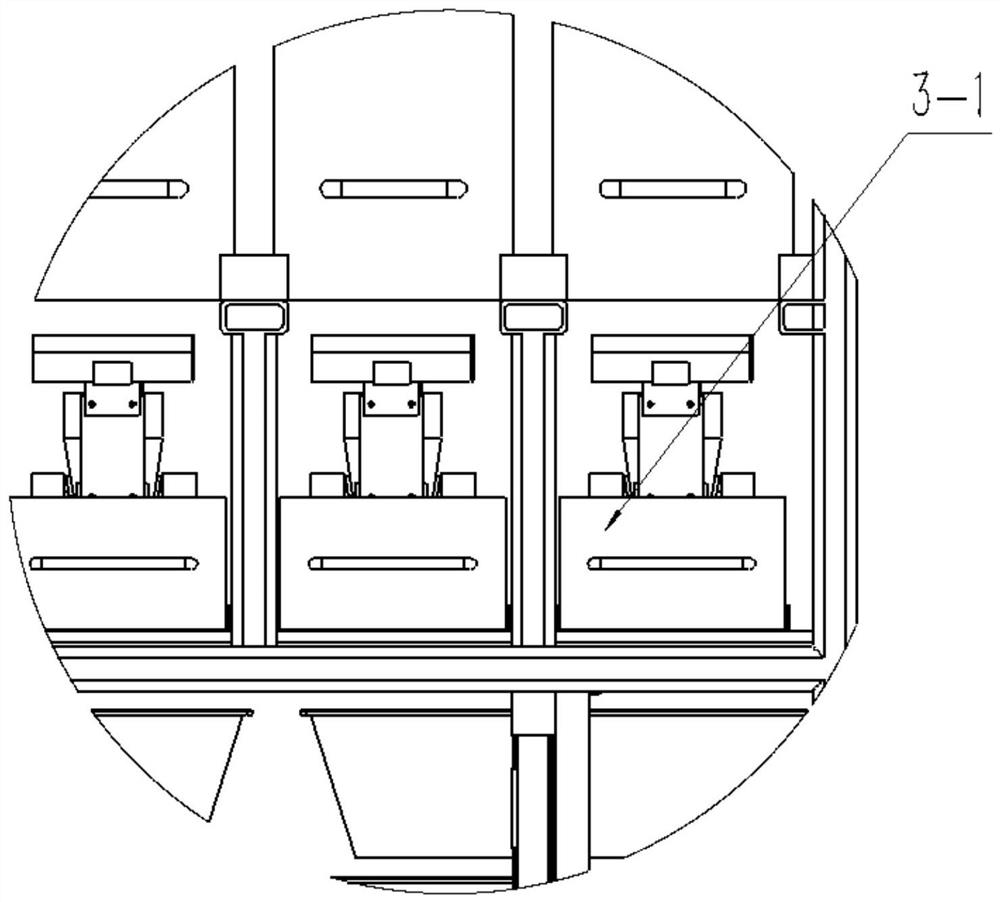

[0112] The function that the present invention can realize is set forth below by the collocation of chafing dish bottom material:

[0113] There are 12 kinds of spices such as star anise, kaempferum, cinnamon, cumin, grass fruit, comfrey, bay leaf, vanilla, clove, rock sugar, dried chili, and wolfberry. Each unit cabinet has 3 material receiving stations, and there are 4 storage boxes directly above each material receiving station, that is, one material receiving station is responsible for receiving 4 kinds of spices. Put the fennel into the material receiving station 1; put the grass fruit, comfrey, fragrant leaves, and vanilla into the material receiving station 2; put the cloves, rock sugar, dried chili, and wolfberry into the material receiving station 3. In order to explain the specific implementation plan more clearly, the hot pot base recipe described below is not complete and only includes one unit cabinet, and the specific weight information is not authentic. It is on...

Embodiment 2

[0127] The function that the present invention can realize is set forth below by the mixing of Chinese medicine prescription:

[0128] For the convenience of explanation, the following only describes the specific flow of the action of a single batching unit, and the action flow of the entire dispensing system is the integration of multiple unit actions.

[0129] There are 12 kinds of traditional Chinese medicines such as red bean, cassia seed, rapeseed, barley, yam, dodder, almond, licorice, Phellodendron, psoralen, Dipsacus, and forsythia. Each unit cabinet has 3 material-receiving stations, and there are 4 storage boxes directly above each material-receiving station, that is, one material-receiving station is responsible for receiving 4 kinds of traditional Chinese medicines. Put 4 kinds of traditional Chinese medicines of job's tears into the receiving station 1; put 4 kinds of traditional Chinese medicines of yam, dodder, almond, and licorice into the receiving station 2; ...

Embodiment 3

[0141] The function that the present invention can realize is set forth below by the collocation of seasoning:

[0142] For the convenience of explanation, the following only describes the specific flow of the action of a single batching unit, and the action flow of the entire dispensing system is the integration of multiple unit actions.

[0143] There are 12 kinds of powdered seasonings such as pepper, fennel, ginger, aniseed, white cardamom, clove, cinnamon, nutmeg, woody, tangerine peel, fragrant leaves and pepper. Each unit cabinet has 3 material receiving stations, and there are 4 material storage boxes directly above each material receiving station, that is, one material receiving station is responsible for receiving 4 kinds of seasonings. Now pepper, fennel, and ginger 1. Put the aniseed material into the material receiving station 1; put the white cardamom, clove, cinnamon, and nutmeg into the material receiving station 2; In order to explain the specific implementat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com