One-step preparation method for Cu-SSZ-13 molecular sieve

A technology of cu-ssz-13 and molecular sieve, which is applied in the field of catalysis, can solve the problems of high cost, lower market competitiveness, complex molecular sieve process, etc., and achieve the effect of easy implementation, excellent catalytic performance, and simple and reliable synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

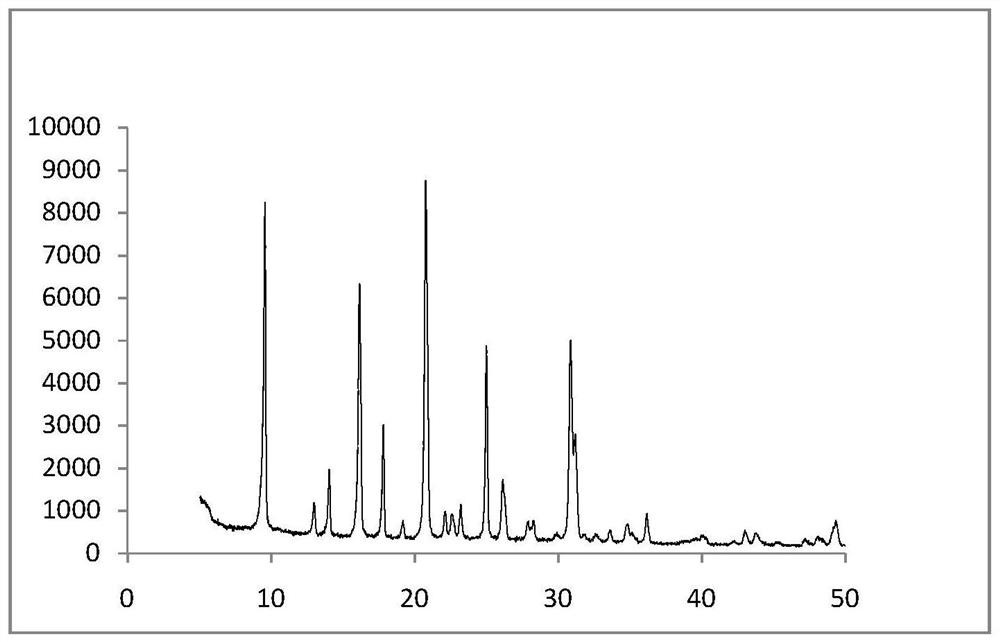

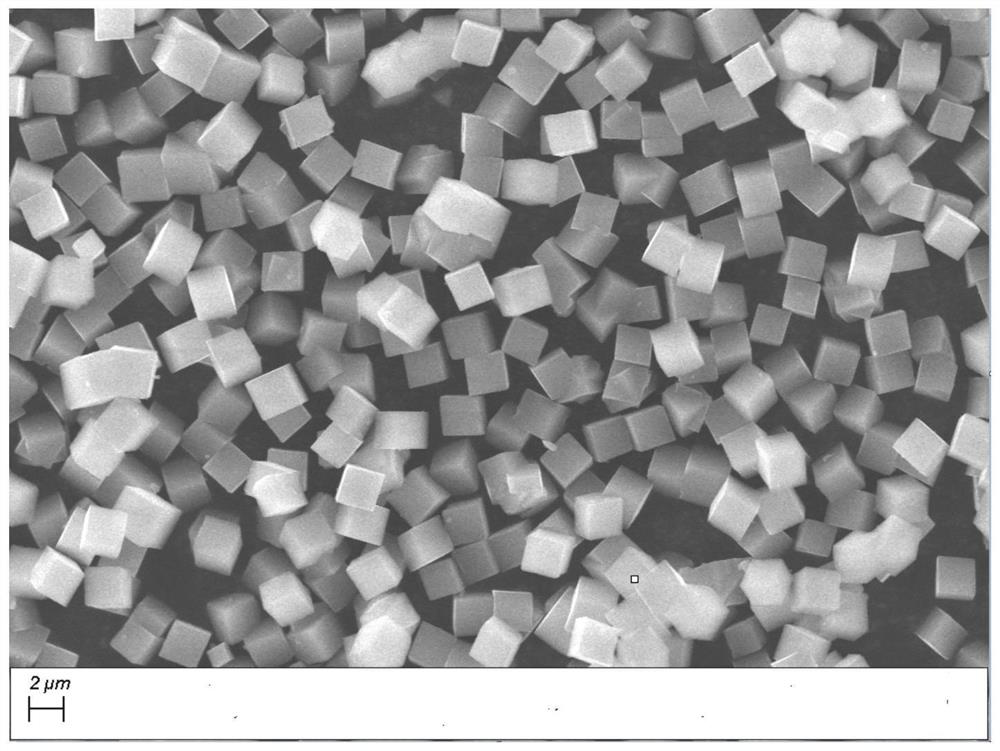

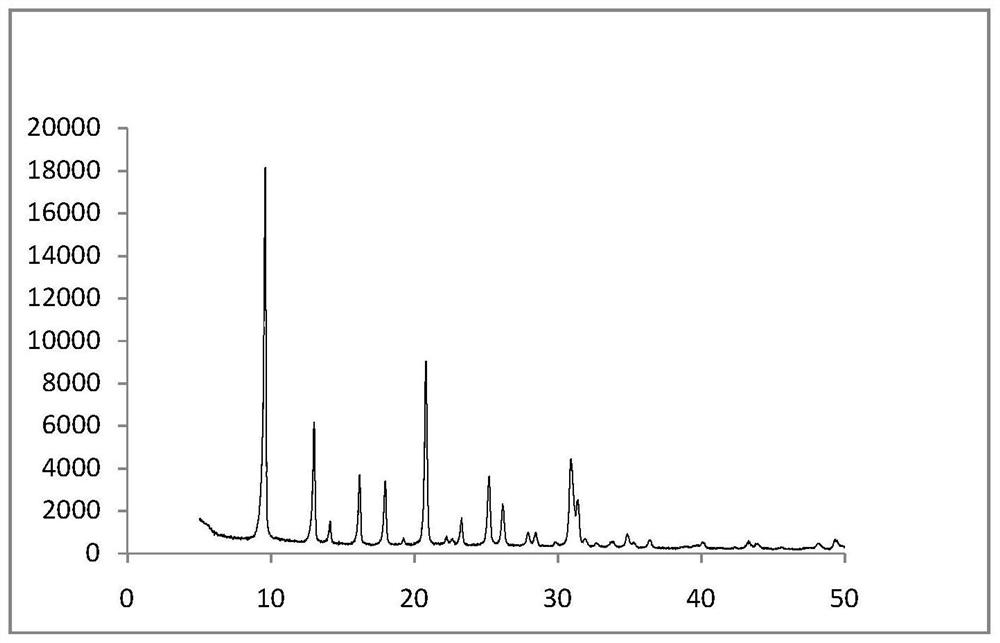

Image

Examples

preparation example Construction

[0022] The preparation method of the molecular sieve provided by the embodiment of the present invention comprises:

[0023] The invention provides a method for preparing Cu-SSZ-13 molecular sieve in one step, comprising:

[0024] Step S110: mixing the template agent, modified copper silica gel, and aluminum source together in an alkaline aqueous solution, and performing a gelation reaction to obtain a gel;

[0025] Step S120: Under the action of the seed crystal, the gel undergoes a crystallization reaction to obtain a crystallized product;

[0026] Step S130: Calcining the crystallized product to obtain Cu-SSZ-13 molecular sieve.

[0027] Compared with the prior art, in the preparation method of Cu-SSZ-13 molecular sieve provided by the present invention, template agent, modified copper-silicon source, aluminum source are used as raw materials, which are mixed together in an organic alkaline aqueous solution to carry out Gelation reaction, and then under the action of the ...

Embodiment 1

[0038] This embodiment provides a method for preparing Cu-SSZ-13 molecular sieves in one step, comprising the following steps:

[0039] Embodiment one:

[0040] Step S110: Add tetrapropylammonium hydroxide, modified copper silica gel, aluminum sulfate, and an aqueous solution containing N,N,N-trimethyl-1-adamantyl ammonium hydroxide (mass Concentration is 25.0%) and deionized water, stirred at room temperature for 1h to form a gel; wherein, the molar ratio of N,N,N-trimethyl-1-adamantyl ammonium hydroxide to silicon in the modified copper silica gel is 0.08 :1, the molar ratio of silica and aluminum sulfate of modified copper silica gel is 25:1, the copper atomic mass ratio content of modified copper silica gel is 0.04, the silica of tetrapropyl ammonium hydroxide and modified copper silica gel The molar ratio is 0.4:1.

[0041]Step S120: Move the gel into the hydrothermal reaction kettle, add seed crystals, seal it well, place the hydrothermal reaction kettle in a blast ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com