{P6Mo18O73}-based metal organic framework porous electrode material and preparation method and application thereof

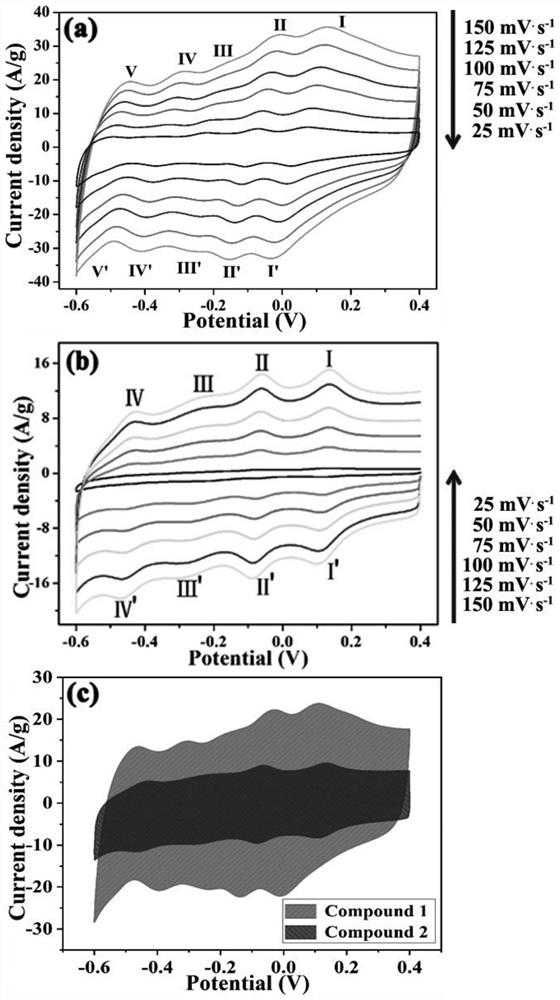

A {p6mo18o73}, porous electrode technology, applied in the field of supercapacitor electrode materials, can solve the problems that it is difficult to combine to form multi-acid-based MOF materials, hinder the functionalization of POMs, and have fewer bonding active sites, so as to improve cycle stability , improve the stability of the solution, and improve the effect of superelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] a{P 6 Mo 18 o 73} The preparation method of base MOF porous electrode material, comprises the following steps:

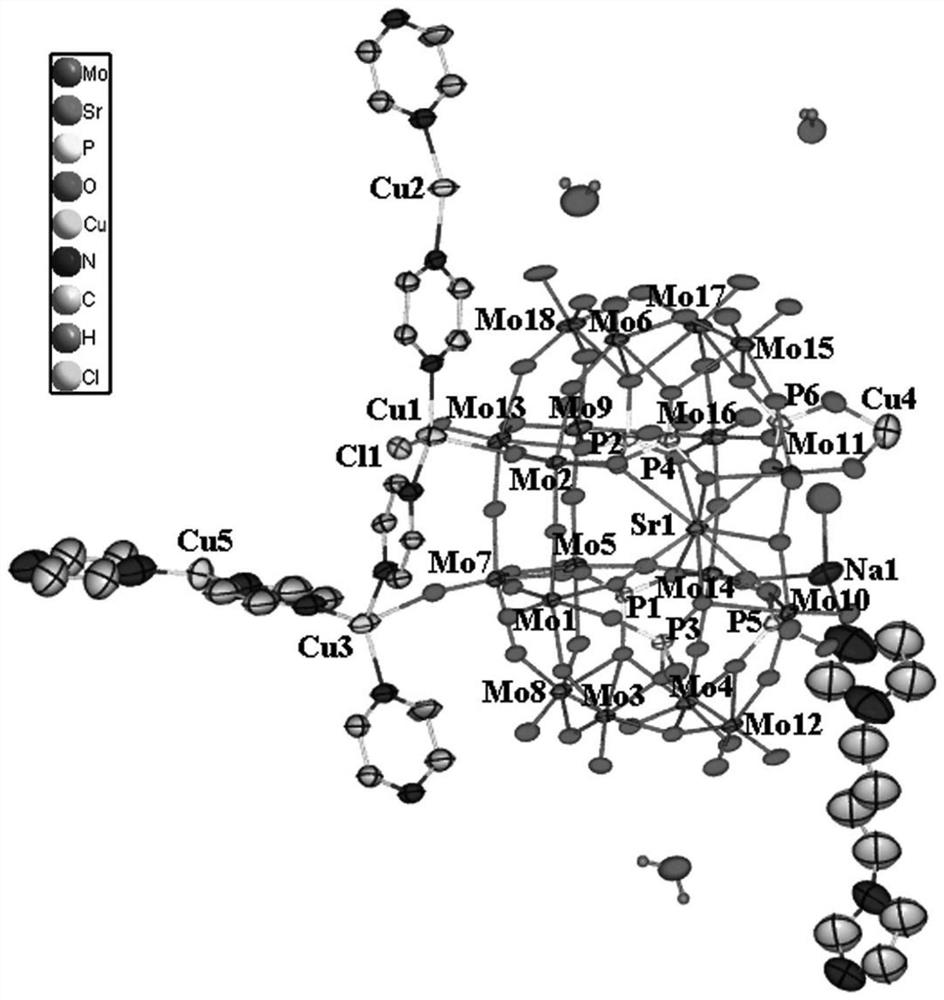

[0040] Will (NH 4 ) 6 Mo 7 o 24 2H 2 O (1.855g, 1.5mmol), CuAc 2 ·H 2 O (0.605g, 3.0mmol), 1,4-bis(1,2,4-triazole) butane (0.286g, 1.5mmol), pyrazine (0.120g, 1.5mmol), H 3 PO 4 (1 mL, 19 mmol), SrCl 2 ·6H 2 O (0.534g, 2.0mmol) and H 2 O (27mL, 1.5mol) mixed and stirred at room temperature for 30min, adjusted the pH to 3.0 with 1mol / L NaOH solution to obtain a reaction solution, sealed the reaction solution in a 50mL Teflon-lined stainless steel reactor, and placed the reactor in Heat up to 160°C in an oven and react for 120h, then cool naturally to room temperature, filter and collect dark blue crystals, wash the crystals thoroughly with distilled water, and dry at room temperature to obtain {P 6 Mo 18 o 73}-based MOF porous electrode material, the product yield is 47%, and its molecular formula is:

[0041] where (pz = pyrazine; btb = 1,4...

Embodiment 2

[0043] a{P 6 Mo 18 o 73} The preparation method of base MOF porous electrode material, comprises the following steps:

[0044] Will (NH 4 ) 6 Mo 7 o 24 2H 2 O (2.1642g, 1.75mmol), CuAc 2 ·H 2 O (0.504g, 2.5mmol), 1,4-bis(1,2,4-triazole) butane (0.286g, 1.5mmol), pyrazine (0.120g, 1.5mmol), H 3 PO 4 (1.2mL, 22.8mmol), SrCl 2 ·6H 2 O (0.6675g, 2.5mmol) and H 2 O (27mL, 1.5mol) mixed and stirred at room temperature for 40min, adjusted the pH to 2.8 with 1mol / L NaOH solution to obtain a reaction solution, sealed the reaction solution in a 50mL Teflon-lined stainless steel reactor, and placed the reactor in Heat up to 162°C in an oven and react for 118h, then cool naturally to room temperature, filter and collect dark blue crystals, wash the crystals thoroughly with distilled water, and dry at room temperature to obtain {P 6 Mo 18 o 73}-based MOF porous electrode material, its molecular formula is: C 28 h 43 ClCu 4 Mo 18 N 16 NaO 78 P 6 Sr.

Embodiment 3

[0046] a{P 6 Mo 18 o 73} The preparation method of base MOF porous electrode material, comprises the following steps:

[0047] Will (NH 4 ) 6 Mo 7 o 24 2H 2 O (2.473g, 2mmol), CuAc 2 ·H 2O (0.807g, 4.0mmol), 1,4-bis(1,2,4-triazole) butane (0.286g, 1.5mmol), pyrazine (0.120g, 1.5mmol), H 3 PO 4 (1.1 mL, 21 mmol), SrCl 2 ·6H 2 O (0.4g, 1.5mmol) and H 2 O (27mL, 1.5mol) mixed and stirred at room temperature for 45min, adjusted the pH to 3.2 with 1mol / L NaOH solution to obtain a reaction solution, sealed the reaction solution in a 50mL Teflon-lined stainless steel reactor, and placed the reactor in Heat up to 158°C in an oven and react for 122h, then cool naturally to room temperature, filter and collect dark blue crystals, wash the crystals thoroughly with distilled water, and dry at room temperature to obtain {P 6 Mo 18 o 73}-based MOF porous electrode material, its molecular formula is: C 28 h 43 ClCu 4 Mo 18 N 16 NaO 78 P 6 Sr.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com