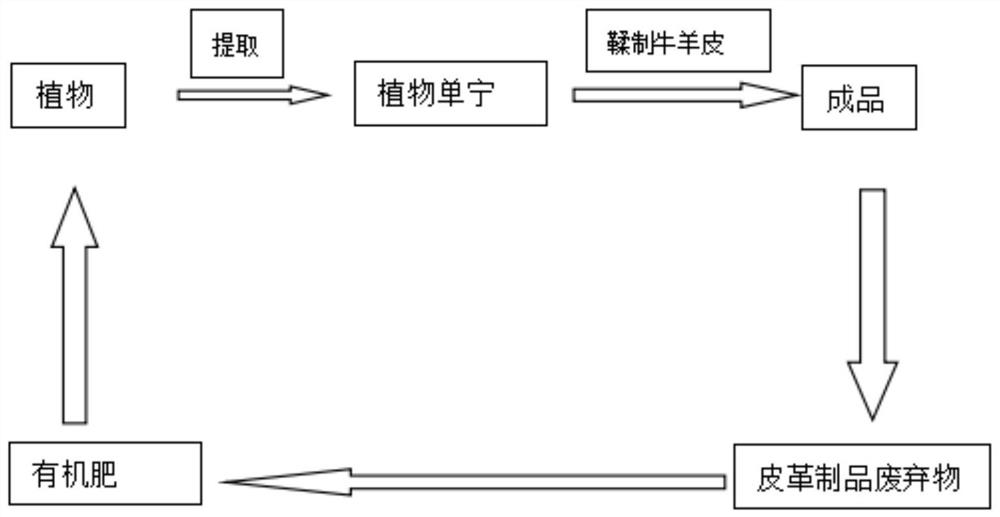

Novel Ecotan leather tanning process

A leather product and tanning technology applied in the new Ecotan leather tanning process to achieve low cost and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a new Ecotan leather tanning process, the process comprising the steps of:

[0041] (1) Extract tanning from plants to obtain plant tannins as tanning preparations;

[0042] (2) The process of immersing, brutal, dispel, and soaked;

[0043] (3) Add the pick-up 10-15 wt% of the acid skin obtained by adding step (2) to pre-tanning; then pressing the water, returning water, neutralization Further, 20-40 wt% of the tannin and 5-15% fatal fats were taken, and the filling of the skin and leather products were performed.

[0044] (4) The leather products obtained by step (3) are used as organic fertilizer raw materials for agriculture.

Embodiment 2

[0046] This embodiment provides a new Ecotan leather tanning process, the process comprising the steps of:

[0047] (1) Grinding the chestnut, forming wood chips, adding hot water to extract, using 80-100 mesh sieve filtration, obtaining the filtrate, purified, and again using 80-100 mesh screen filtration, filtrate, spray drying, to obtain the tanning preparation;

[0048] (2) 1x weight of cold water was added to the skin for 24 hours, then the pneumatic grafting agent was added to the gray skin, then the gray skin, then the gray skin, added to the gray skin weight. 2% of the pendant for 30 minutes; the pH of the solution was adjusted with an acid adjusted for 8 hours, and it became acids;

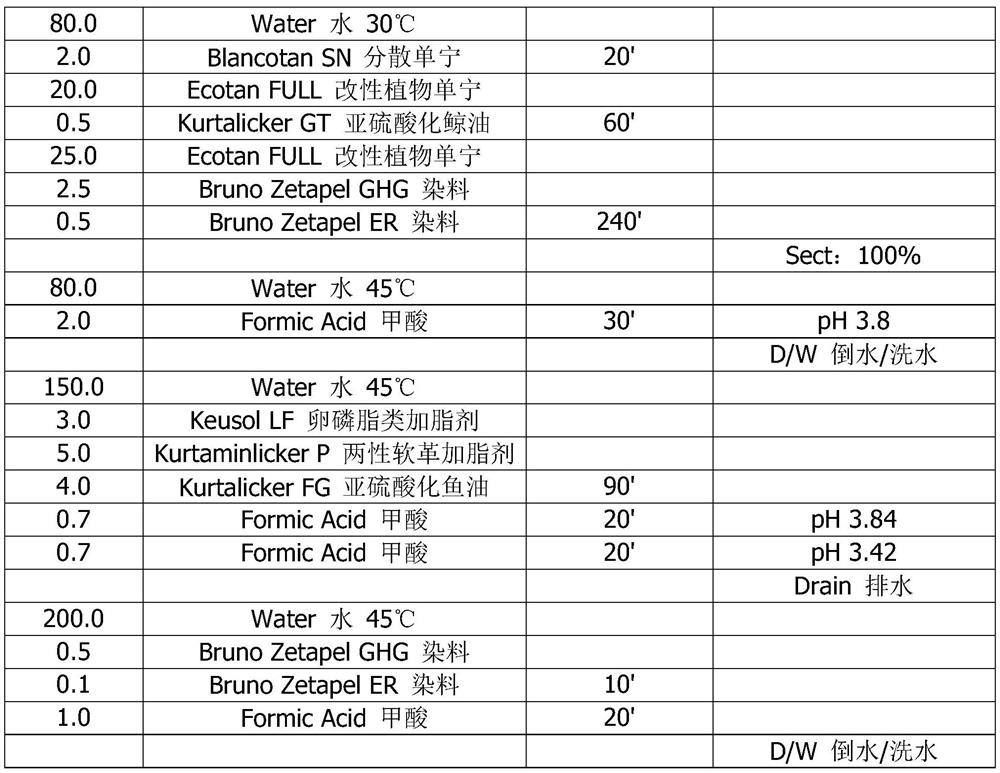

[0049] (3) Add the pick-up 10 wt% of the pickled skin 10 wt% obtained from the pickled skin obtained by the step (2) to pre-tanning; then squeezing, returning water, neutralization, Take the tannin 40 wt% of the tannyl and 15% of the fat-lipid to carry out retanning filled to obtain a skin an...

Embodiment 3

[0052] This embodiment provides a new Ecotan leather tanning process, the process comprising the steps of:

[0053] (1) Grinding the solid wood, forming wood chips, adding hot water to extract, using 80-100 mesh sieve filtration, resulting in the filtrate to concentrate to a tannin content of 65%, then purified, then use 80-100 mesh screen filtration The filtrate is sprayed and dried to give the brown crystal to form the tanning formulation for leather use.

[0054] (2) 150% cold water of the sore amount of cold water was added to the skin for 24 hours, and then the pneumatic grafting agent was added to the gray skin, and the gray skin was formed, then the gray skin was added. 3% of the gray skin weight for 20 minutes; the pH of the solution was adjusted with an acid adjusted for 4 hours, and the acid was obtained.

[0055] (3) Take the cold water and 10% of the salt into the drum into the drum for 15 minutes, mix well and uniformly forming saline, adding the like weight of the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com