Lithium-sulfur battery modified diaphragm and preparation method thereof

A lithium-sulfur battery and separator technology, applied in the field of new energy materials and devices, can solve the problems of insignificant inhibition of the shuttle effect, limited polysulfide adsorption capacity, and reduced ionic conductivity of the separator, and achieve ionic conductivity and internal battery. The effect of low resistance, reducing the presence of polysulfides, and inhibiting shuttle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

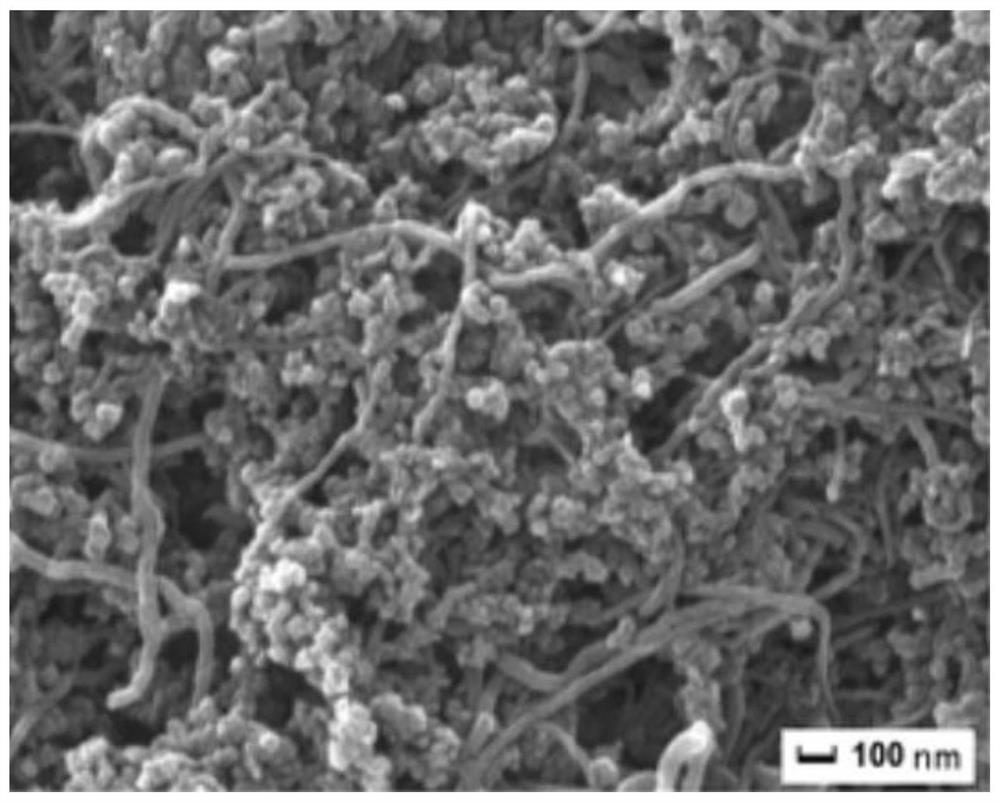

[0039] A modified diaphragm for lithium-sulfur battery, with 8 μm thick polyethylene porous membrane as substrate, the side of the diaphragm substrate opposite to the positive electrode side (when making the battery) is covered with a conductive coating, and the thickness of the conductive coating is 3 μm. The conductive coating includes a conductive framework and triphenylphosphine, MoO loaded in the conductive framework 2 , the conductive skeleton has a microporous structure. The raw materials of the conductive framework include Ketjen black, single-walled carbon nanotubes, vapor-grown carbon fibers, layered Ti 3 C 2 , of which Ketjen black, single-walled carbon nanotubes, vapor-grown carbon fibers, layered Ti 3 C 2 The mass ratio is 0.5:3:7:3.

[0040] The preparation method of the lithium-sulfur battery modified diaphragm of the present embodiment comprises the following steps:

[0041] (1) Under anaerobic conditions, according to the mass ratio, 2.5 parts of tripheny...

Embodiment 2

[0047] A modified diaphragm for a lithium-sulfur battery, which uses an 8 μm thick polypropylene porous membrane as a diaphragm substrate, and a conductive coating is coated on the side of the diaphragm substrate facing the positive side, and the thickness of the conductive coating is 4 μm. The conductive coating includes a conductive skeleton and triphenylphosphine, CeO 2 、VO 2 , the conductive skeleton has a microporous structure. The raw materials of the conductive framework include Ketjen black, super P, single-wall carbon nanotubes, and graphene, and the mass ratio of Ketjen black, super P, single-wall carbon nanotubes, and graphene is 2:1:8:1.4.

[0048] The preparation method of the lithium-sulfur battery modified diaphragm of the present embodiment comprises the following steps:

[0049] (1) Under anaerobic conditions, according to the mass ratio, 4 parts of triphenylphosphine, 2 parts of Ketjen black, 1 part of super P, 8 parts of single-walled carbon nanotubes, 1.4...

Embodiment 3

[0055] A modified separator for a lithium-sulfur battery, with a 10 μm thick polypropylene porous membrane as a separator base, and a conductive coating on the side of the separator base facing the positive side, the thickness of which is 6 μm. The conductive coating includes a conductive framework and triphenylphosphine, MoS loaded in the conductive framework 2 , the conductive skeleton has a microporous structure. The raw materials of the conductive framework include super P, multi-walled carbon nanotubes, graphene, layered Ti 3 C 2 , of which super P, multi-walled carbon nanotubes, graphene, layered Ti 3 C 2 The mass ratio is 3:0.5:1:4.

[0056] The preparation method of the lithium-sulfur battery modified diaphragm of the present embodiment comprises the following steps:

[0057] (1) Under anaerobic conditions, according to the mass ratio, 1 part of triphenylphosphine, 3 parts of super P, 0.5 parts of multi-walled carbon nanotubes, 1 part of graphene, and 4 parts of l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com