Negative electrode material, electrochemical device, and electronic apparatus

A negative electrode material, electrochemical technology, applied in the field of electrochemistry, can solve unsatisfactory problems, achieve high mechanical stability, improve electrical conductivity, and low expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

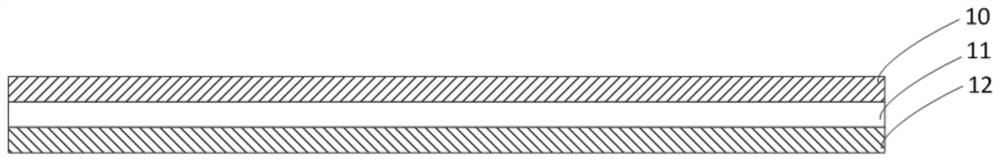

[0039] In some embodiments of the present application, a method for preparing an electrochemical device is also proposed, including the following steps:

[0040] Negative material preparation:

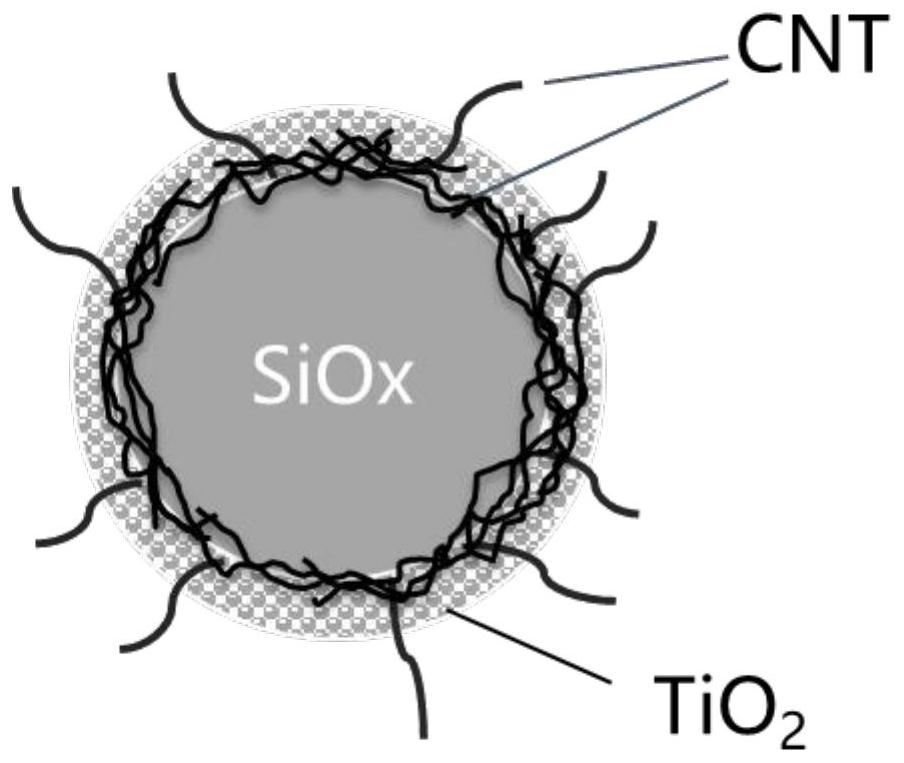

[0041] Step 1: Add silicon-based powder and carbon nanotube slurry in a certain proportion to MSK-SFM-10 vacuum stirrer and stir for 180 minutes at a revolution speed of 10r / min to 40r / min to obtain slurry.

[0042] Step 2: Transfer the slurry obtained in step 1 to the centrifugal turntable nozzle of the spray drying granulator, and spray dry according to the centrifugal speed of 5000r / min to obtain powder, wherein the inlet temperature of the spray drying granulator is 260°C, and the outlet temperature is 105°C.

[0043] Step 3: The powder obtained in step 2 is sieved, and the sieve is selected from 1000 mesh to 8000 mesh.

[0044] Step 4: Add the sieved powder obtained in step 3 to the ethanol solution, then add the titanium dioxide precursor (such as isopropyl titanate, tetrabutyl...

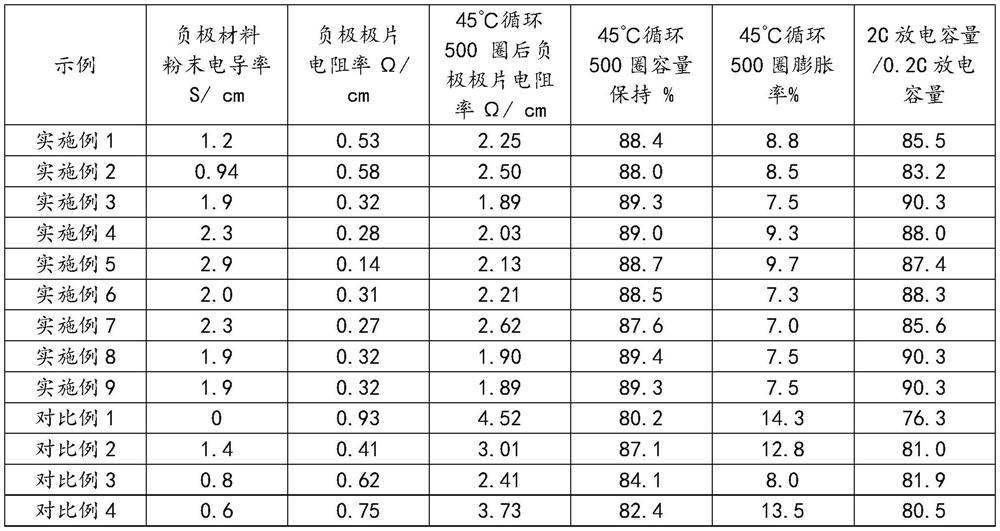

Embodiment 1

[0057] Li-ion battery preparation:

[0058] Step (1): Add 500g SiOx (0.5<x<1.6) and 500g carbon nanotube (CNT) slurry (1% solid content) into the MSK-SFM-10 vacuum stirrer, stir for 180min, revolution speed 10r / min to 40r / min.

[0059] Step (2): Transfer the slurry in step (1) to the centrifugal turntable nozzle of the spray drying granulator, and the centrifugal speed is 5000r / min to form tiny droplets. The inlet temperature of the spray drying granulator is 260°C, the outlet temperature is 105°C, and the powder is collected by cooling.

[0060] Step (3): The powder in step (2) is sieved, and the sieve is selected from 1000 mesh to 8000 mesh to obtain a powder with a Dv50 of 5.0 μm

[0061] Step (4): Add 500g of the powder sieved in step (3) to 1000mL ethanol solution, then add 30g of isopropyl titanate to it, rotate at 800r / min, stir and disperse for 30min, add 10ml of deionized water and stir After 30 minutes, filter and wash with alcohol solution to obtain powder.

[...

Embodiment 2

[0068] The only difference between embodiment 2 and embodiment 1 is that the mass of CNT in step (1) is 250g, and the rest are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dv50 | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap