Gradient porous bioactive ceramic coating material and preparation method thereof

A technology of bioactive ceramics and gradient porosity, which is applied in coating, metal material coating technology, tissue regeneration, etc., can solve the problems of further improvement and low similarity, and achieve the promotion of osseointegration and good biological performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

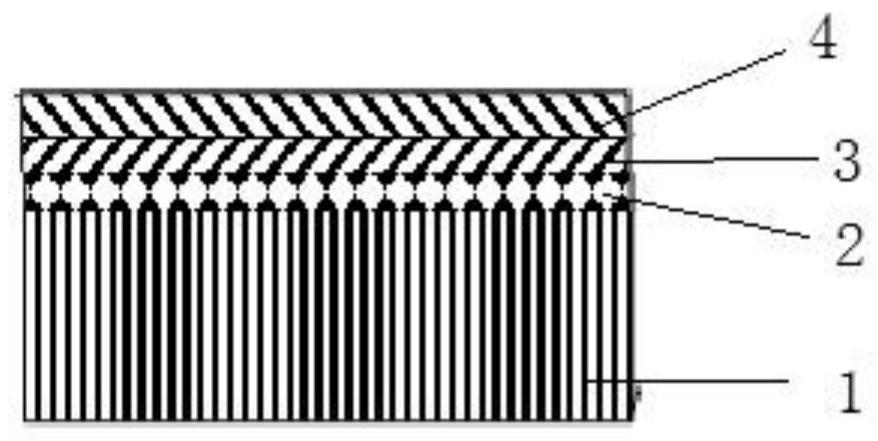

[0049] A gradient porous bioactive ceramic coating material according to an embodiment of the present invention, its structural schematic diagram is as follows figure 1 As shown, it includes a titanium base 1 and a gradient porous bioactive ceramic coating on the surface of the titanium base 1 . The gradient porous bioactive ceramic coating includes an Ag barrier layer 2 , a hydroxyapatite / Ag composite transition layer 3 , and a hydroxyapatite bioceramic layer 4 in sequence from the inside to the outside. Wherein, the mass fraction of Ag in the hydroxyapatite / Ag composite transition layer 3 is 25%, and the mass fraction of HA (hydroxyapatite) is 75%; the thickness of the Ag barrier layer 2 is about 200 μm-240 μm, and the The thickness of the stone / Ag composite transition layer 3 is about 180 μm-200 μm. The hydroxyapatite bioceramic layer 4 has a porous structure, the average pore diameter of the hydroxyapatite bioceramic layer 4 is about 7.22±1.88 μm, and the thickness of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com