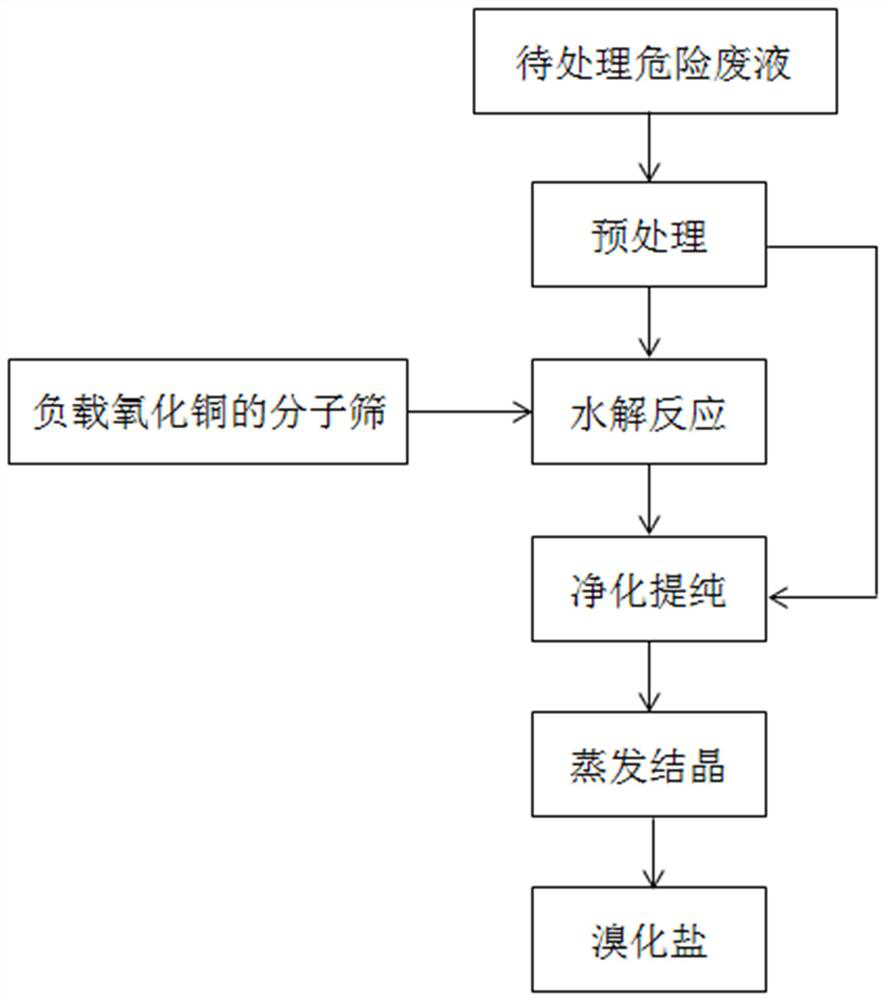

A method for recovering bromine in hazardous waste liquid containing brominated aromatics

A brominated aromatic hydrocarbon and dangerous technology, applied in the field of recovering bromine, can solve the problems of reducing the service life of the incinerator, corrosion of the incinerator, and high treatment costs, and achieve the effects of good economic benefits, improved recovery efficiency, and high product purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

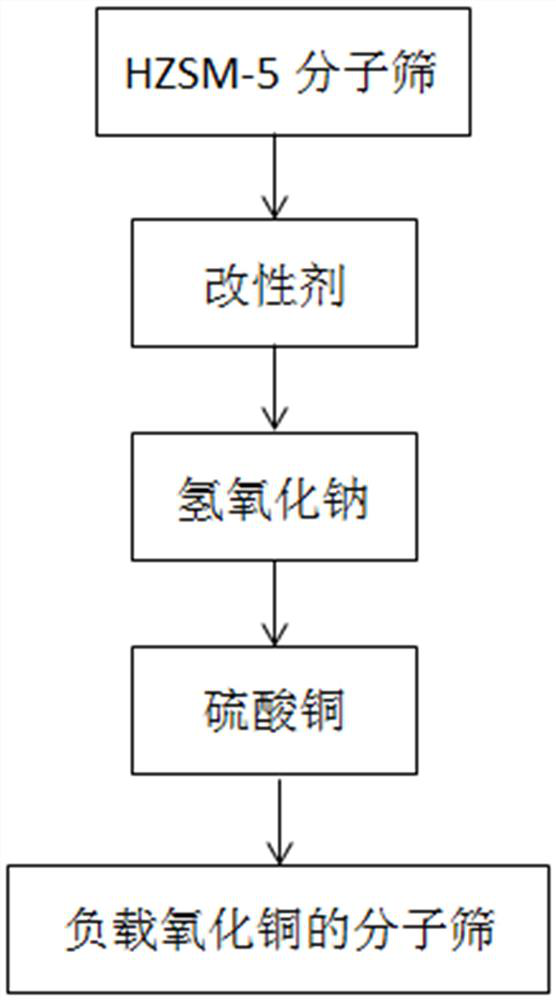

[0048] The application provides a method for preparing a molecular sieve loaded with copper oxide, which specifically includes the following steps:

[0049] a. Modification of the HZSM-5 molecular sieve: modify the HZSM-5 molecular sieve with a modifier, and dry at high temperature to obtain the molecular sieve A.

[0050] Wherein, the modifying agent is a mixed solution composed of sodium fluoride, trifluoroacetic acid and sulfuric acid. Among them, the weight ratio of sodium fluoride to HZSM-5 molecular sieve is (4-6):1. The weight ratio of sulfuric acid to HZSM-5 molecular sieve is (1.5-2.5):1. The weight ratio of trifluoroacetic acid to HZSM-5 molecular sieve is (1.4-2.8):1. Further, the molar concentration of sulfuric acid is 9.2-13.8mol / L. The temperature of the modification treatment is 90-110° C., and the modification time is 4-6 hours.

[0051] The temperature of high-temperature drying is 120-140°C, and the drying time is 6-9h.

[0052] b. Treating the molecular...

preparation example 1-6

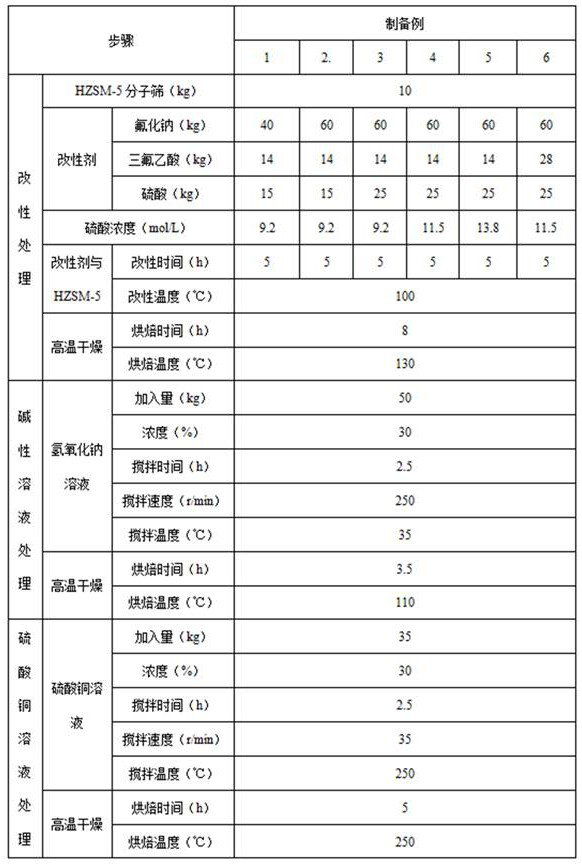

[0069] Preparation Examples 1-6 respectively provide a method for preparing molecular sieves loaded with copper oxide. The difference between Preparation Examples 1-6 lies in the different parameters in the preparation methods, as shown in Table 1 for details.

[0070] The preparation method of the above-mentioned molecular sieve loaded with copper oxide specifically comprises the following steps:

[0071] a. Modification of the HZSM-5 molecular sieve: modify the HZSM-5 molecular sieve with a modifier, and dry at high temperature to obtain the molecular sieve A. Wherein, the modifying agent is a mixed solution composed of sodium fluoride, trifluoroacetic acid and sulfuric acid, and the respective addition amounts are shown in Table 1.

[0072] b. Mix the sodium hydroxide solution with the molecular sieve A and fully stir, process the molecular sieve A obtained in step a, and roast at high temperature until dry to obtain the molecular sieve B.

[0073] c. Treating the molecul...

preparation example 7-14

[0077] Preparation Examples 7-14 respectively provide a method for preparing molecular sieves loaded with copper oxide. The difference between Preparation Examples 7-14 and Preparation Example 1 lies in the different parameters in the step of "modification of HZSM-5 molecular sieve", as shown in Table 2 for details.

[0078] Table 2 Parameters in the step of "modification of HZSM-5 molecular sieve" in preparation examples 7-14

[0079]

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com