Elastic sheath-core fiber and preparation method thereof

A technology of elastic leather and fiber, which is applied in fiber processing, textiles, papermaking, yarn, etc., can solve the problems of single structure, limit the practical application of stretchable conductive fibers, poor performance stability, etc., and achieve improved roughness and regular spiral structure High degree and controllability, the effect of increasing richness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

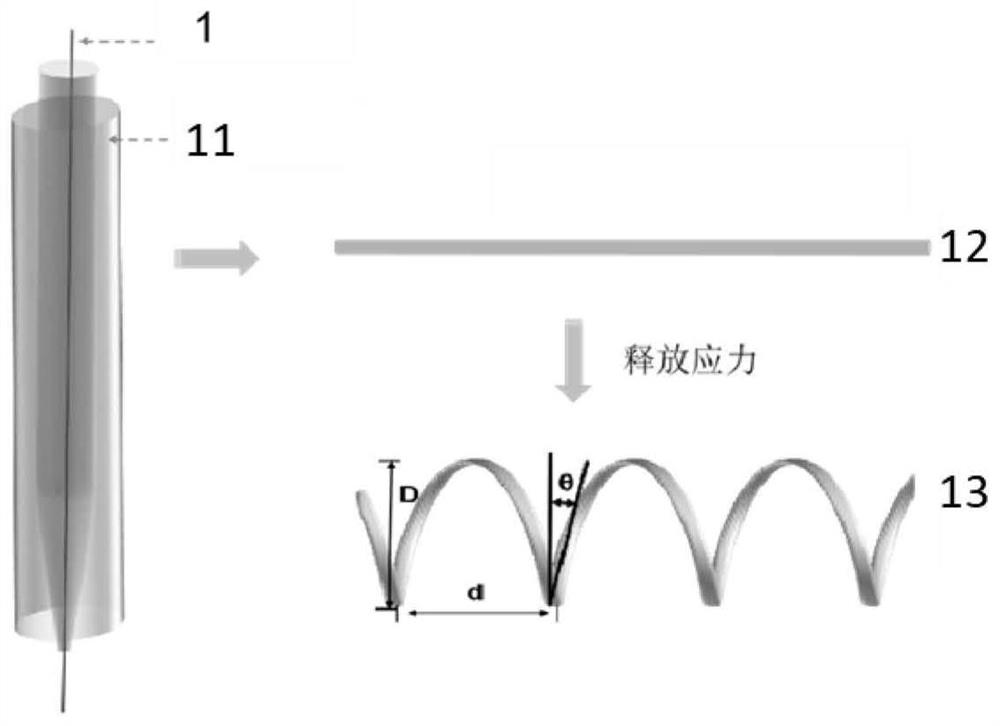

[0056] The preparation method of elastic sheath-core fiber provided by the invention comprises the following steps:

[0057] S1. Pre-drawing the core filament 1 according to the preset drawing ratio;

[0058] S2. Prepare cortex solution 11;

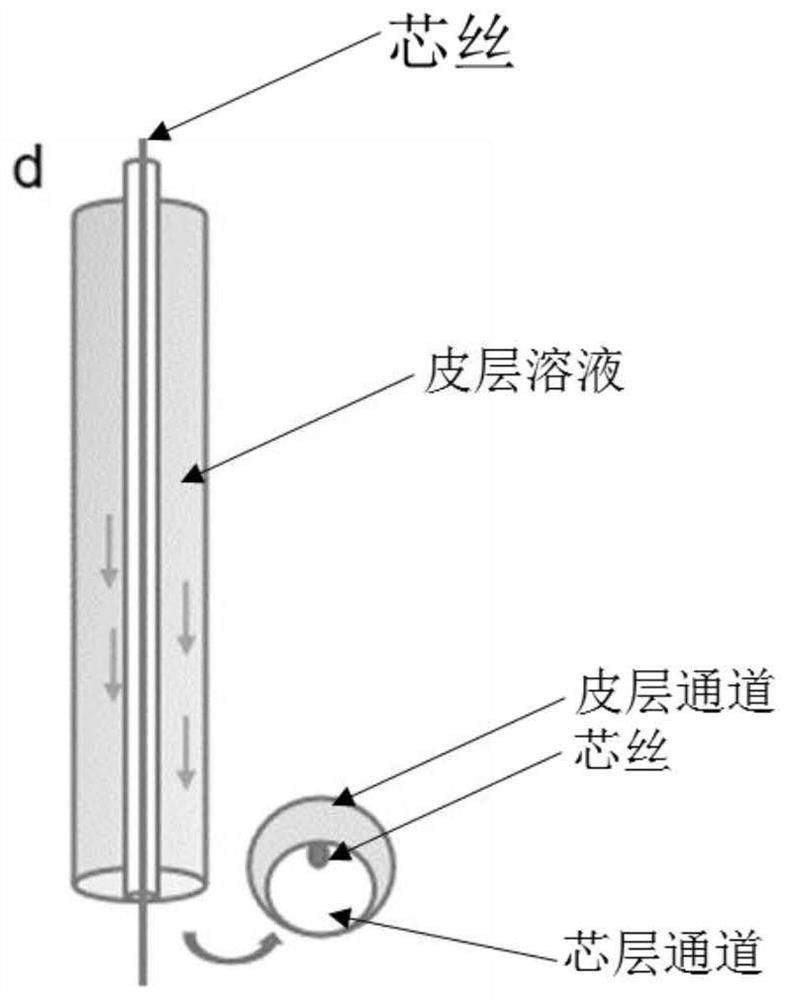

[0059] S3. Coating the skin layer solution 11 on the surface of the pre-stretched core filament 1 to form a film through the microfluidic coating coating technology in solid-liquid form, and then release the pre-stretch of the core filament 1 stress, to obtain elastic sheath-core fibers.

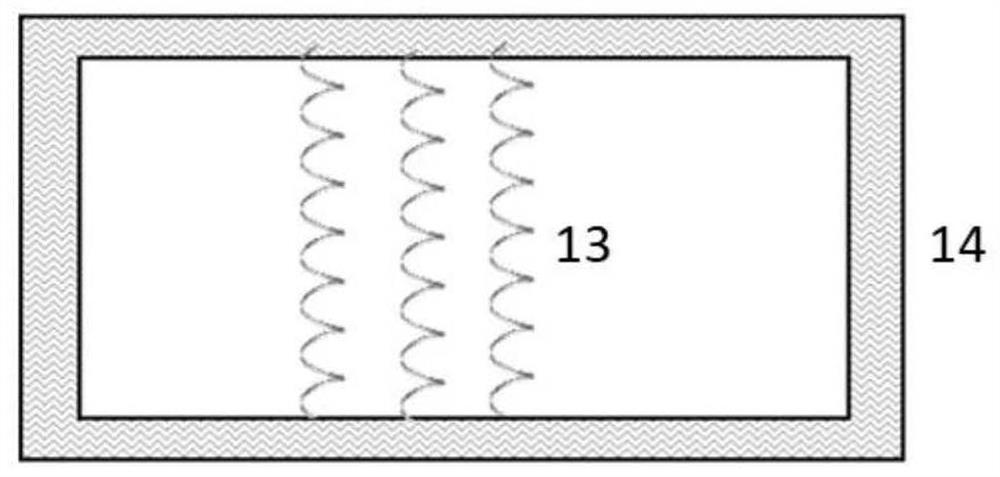

[0060] By adopting the above technical scheme, the present invention uses a polymer with certain film-forming properties as the skin layer material, and pre-stretched elastic filaments as the core layer material, controls the spinning process, and prepares a kind of elastic fiber that is different from the conventional single linear elastic fiber. The different novel three-dimensional helical elastic skin-core composite fibers13. The elastic sheath-c...

Embodiment 1

[0082] A preparation method of elastic sheath-core fiber, comprising the following steps:

[0083] (1) Prepare the cortex solution: configure ethyl acetate and toluene into a mixed solvent with a mixing ratio of 3:1, and set aside. Weigh an appropriate amount of SBS masterbatch and slowly add it to the mixed solvent, stir magnetically at room temperature for 12 hours until the SBS particles are completely dissolved, and prepare a 15% SBS solution with a clear and transparent texture.

[0084] (2) The core material is 140D PU filament, and the pre-drawing is 300%.

[0085] (3) Utilize microfluidic coating technology, through microfluidic chip channel design, use SBS solution as the skin layer, wrap on the surface of the pre-drawn core layer PU filament, at the chip outlet, wrap on the surface of the PU filament The SBS solution quickly solidified into a film, and then the pre-drawing stress was released, and the PU fiber retracted naturally, and the SBS / PU skin-core composite ...

Embodiment 2

[0096] A preparation method of an elastic sheath-core fiber. Compared with the examples, the difference lies in that the mass fraction of SBS is 25%, and the pre-drawing of PU is 200%. Others are substantially the same as in Embodiment 1, and will not be repeated here.

[0097] see Figure 11 As shown, it can be seen that the SBS 25 / PU 200 Micropores were hardly observed on the surface of the composite elastic fiber. This may be due to the decrease of the solvent content in the SBS solution of the cortex, the volume of the solvent-rich phase decreased relative to the total volume, and finally a small amount of micropores were formed on the fiber surface.

[0098] Although the energy loss of the composite elastic fiber prepared under this condition is small, the residual strain is relatively large.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com