Device and method for low-carbon synergistic utilization of extracting gas with high and low concentrations

A low-concentration gas and gas extraction technology, which is applied in the field of low-carbon synergistic utilization of high- and low-concentration gas extraction devices, can solve the problems of high cost and low-concentration gas not being fully utilized, so as to achieve recycling and reduce the greenhouse effect. , the effect of low-cost capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

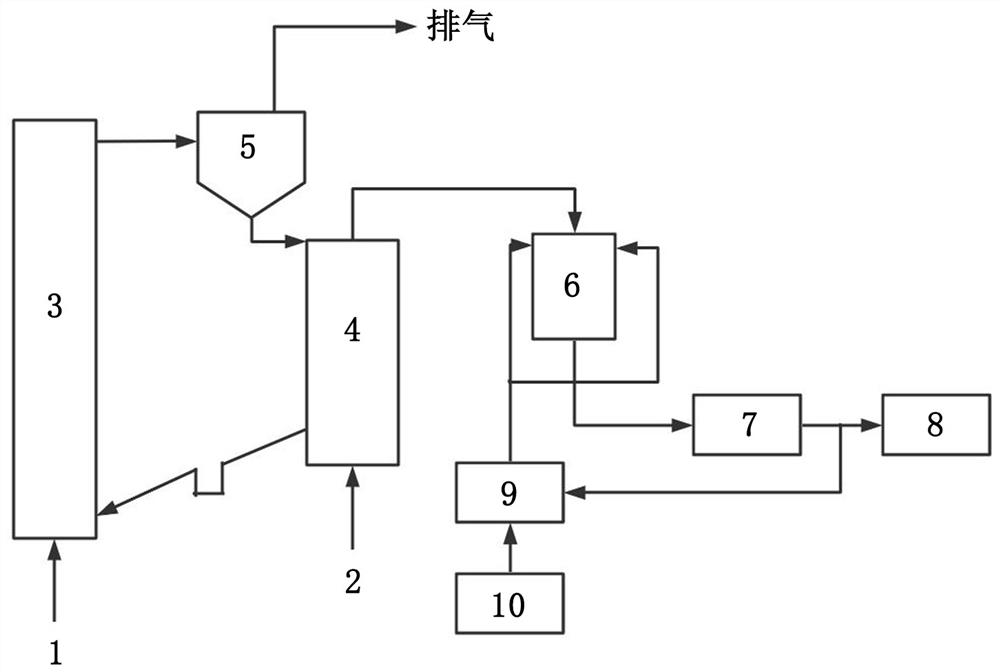

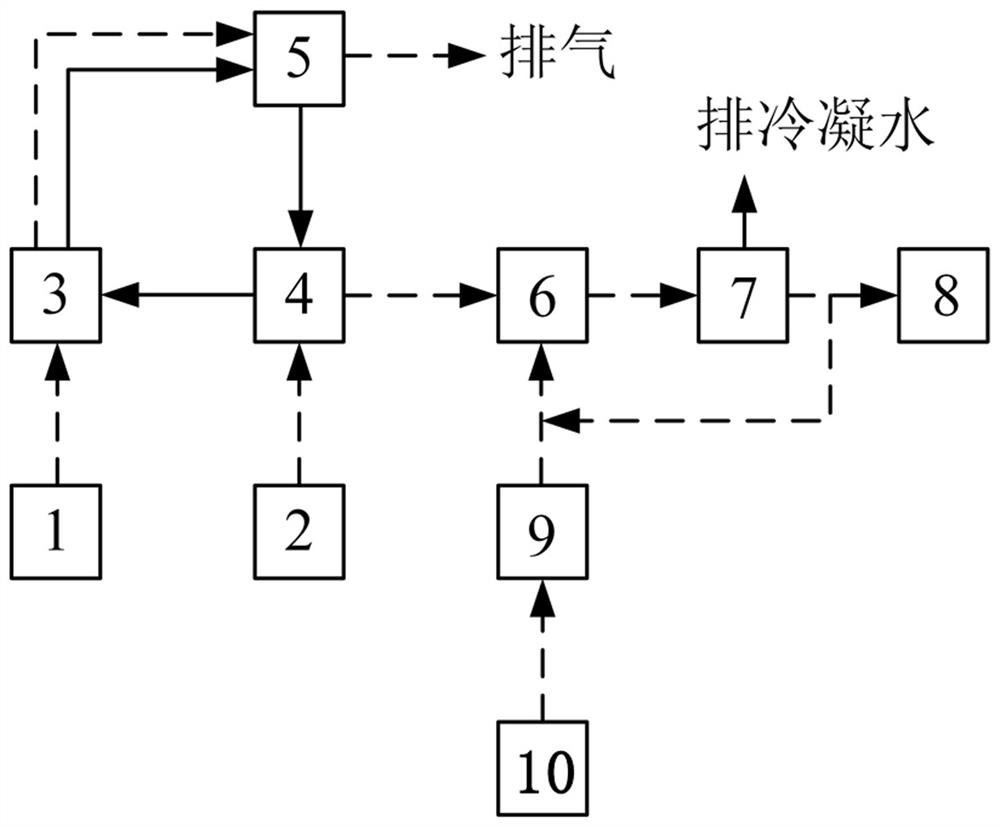

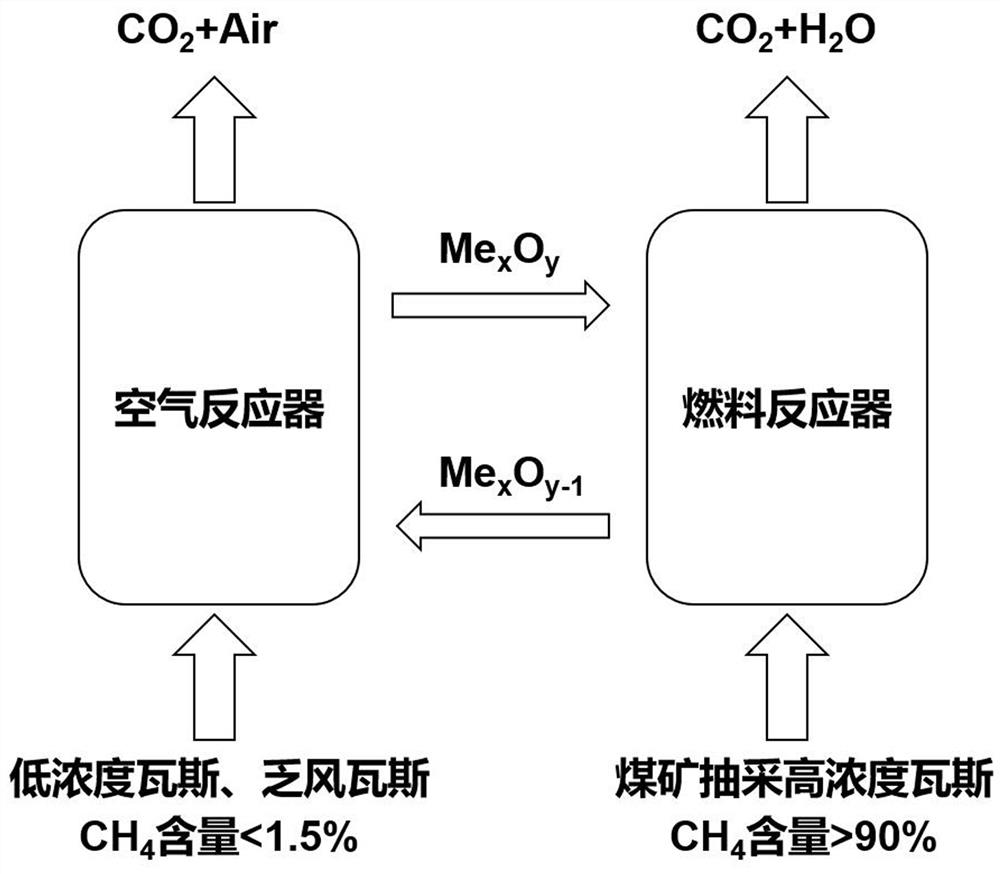

[0046] A device for low-carbon synergistic utilization of high and low concentration gas drainage, see figure 1 and figure 2 , including low-concentration gas 1, high-concentration gas 2, oxygen carrier, air reactor 3, fuel reactor 4, gas-solid separator 5, pure oxygen supplementary combustion device 6, condensing device 7, CO 2 Capture device 8, premixed gas distribution system 9 and air separation unit 10, described fuel reactor 4 comprises the fuel reactor main body that is provided with heating device, the oxygen carrier inlet that is located at the top edge of fuel reactor main body, is located at The gas outlet at the top center of the fuel reactor body, the oxygen carrier outlet at the bottom of the side wall of the fuel reactor body, the high-concentration gas inlet at the bottom of the fuel reactor body, the gas distribution plate at the bottom of the fuel reactor body and The solid feed port located on the side wall of the main body of the fuel reactor and above th...

Embodiment 2

[0049] Same as Example 1, the difference is that the pipeline connecting the air reactor 3 and the gas-solid separator 5, the pipeline connecting the combustion chamber and the pure oxygen supplementary combustion device 6, and the pipeline connected between the pure oxygen supplementary combustion device 6 and the condensing device 7 Both have combustible gas CH 4 、H 2 , CO and O 2 A sensor probe and a temperature-measuring thermocouple, the sensor probe and the temperature-measuring thermocouple are connected to a PLC control system to monitor and control the state and temperature of the gas in the pipeline through the PLC control system.

[0050] The pipeline connecting the air reactor 3 and the fuel reactor 4 is provided with a particle circulation control device and an isolator, and the particle circulation control device and the isolator are used to assist in sending fluidization wind to the side of the air reactor 3 to prevent gas And the particles flow back from the ...

Embodiment 3

[0092] With embodiment 2, the difference is that the preparation method of the oxygen carrier is as follows: the micron Fe 2 o 3 with nanoscale Al 2 o 3 The particles are mixed according to the mass ratio of 1:1 and put into a beaker filled with an equal amount of deionized water. After stirring evenly at a speed of 200r / min, the sample is placed in a drying oven and kept at a constant temperature of 100°C until the water is completely evaporated; Place the dried sample in a muffle furnace, and set the muffle furnace calcination program as follows: at a heating rate of ≤5°C / min, from room temperature to 650°C, and then at a heating rate of ≤2°C / min, from 650°C to 650°C Raise the temperature from ℃ to 1000℃, keep it at 1000℃ for 120min, then cool down from 1000℃ to 650℃ at a cooling rate of ≤2℃ / min, and finally cool down from 650℃ to room temperature at a cooling rate of ≤5℃ / min; use The calcined sample is crushed and sieved by a small crusher, and particles with a particle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com