Gamma-type manganese dioxide composite sulfur positive electrode material, carrier, preparation method and application

A technology of sulfur cathode material and manganese dioxide, which is applied in the field of γ-type manganese dioxide composite sulfur cathode material, carrier and preparation field, can solve the problems of poor conductivity, insufficient reaction of sulfur, low specific capacity of battery, etc., and achieves good rate performance , excellent cycle stability, the effect of improving the discharge specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

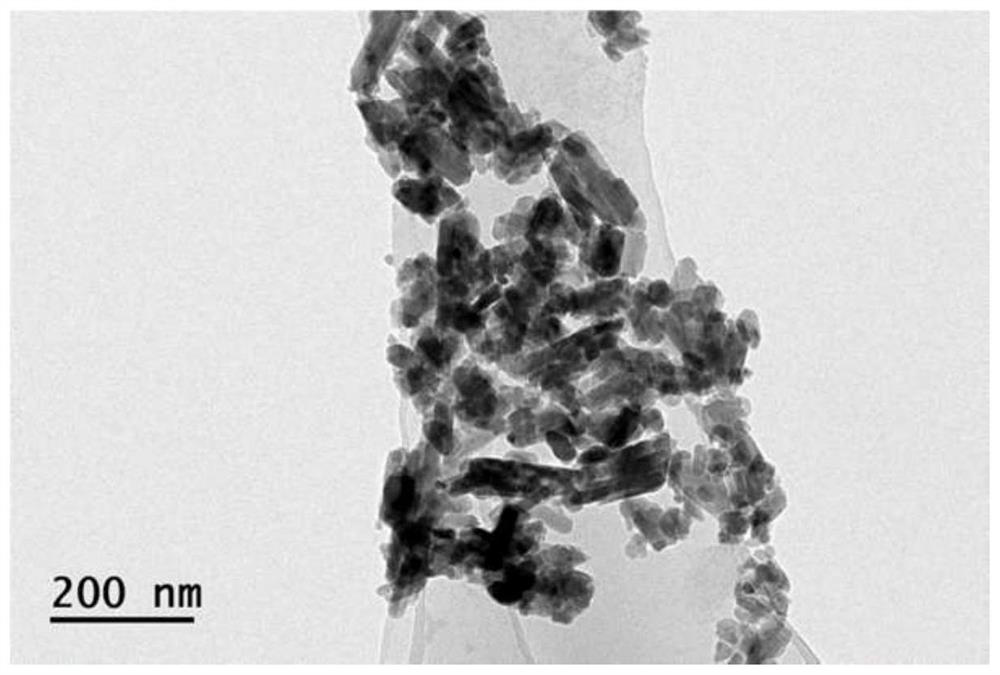

Image

Examples

preparation example Construction

[0033]The third aspect of the present invention provides a method for preparing a γ-type manganese dioxide composite sulfur cathode material, characterized in that the method comprises:

[0034] (1) The carrier and the nano-sulfur powder are mixed for the second time to obtain a second mixture; the second mixture is subjected to second sintering to obtain product A;

[0035] (2) The product A is mixed with a conductive agent and a binder for a third time to obtain a third mixture; the third mixture is slurried with a solvent to obtain a slurry; the slurry is dried to obtain a γ-type manganese dioxide composite sulfur cathode material;

[0036] Wherein, in step (1), the carrier is the carrier provided in the aforementioned first aspect.

[0037] In some embodiments of the present invention, in step (1), the nano-sulfur powder can be obtained commercially, or can be self-produced by conventional methods in the art, for example, adding polysulfide-containing sulfur to sodium thi...

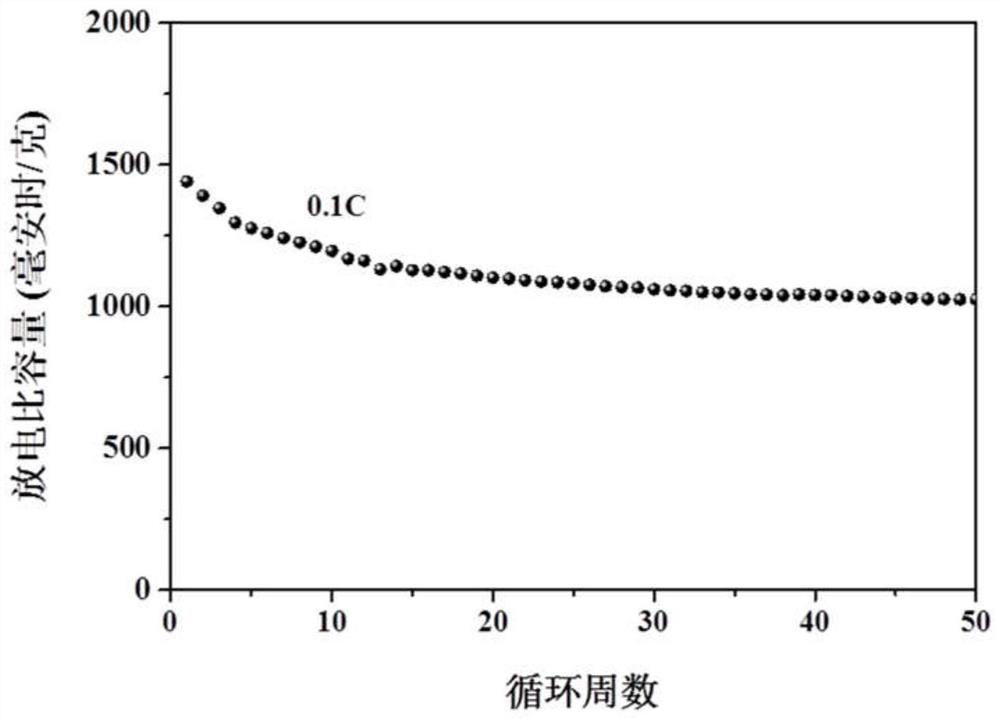

Embodiment 1

[0056] (1) Electrolytic manganese dioxide, lithium nitrate and ammonium molybdate tetrahydrate were ball milled for 2 hours for the first mixing (wherein, the molar ratio of Mn:Li:Mo was 3:1:0.35), and then the obtained first mixture was placed Carry out the first sintering in a tube furnace: raise the temperature to 250°C at a rate of 5°C / min in an argon atmosphere, and keep it for 3 hours; then continue to raise the temperature to 350°C, and keep it for 5 hours; finally lower it to room temperature to obtain the carrier Z1; Among them, the molar ratio of manganese, lithium and molybdenum in Z1 is 3:1:0.35;

[0057] (2) Carrier Z1 and nano-sulfur powder are ball-milled for 2 hours at a mass ratio of 3:7 for the second mixing, and then the second mixture obtained is placed in a polytetrafluoroethylene reactor for sealing under an argon atmosphere, and placed in a vacuum Carry out the second sintering in an oven: the sintering temperature is 155°C, the time is 24h, and after co...

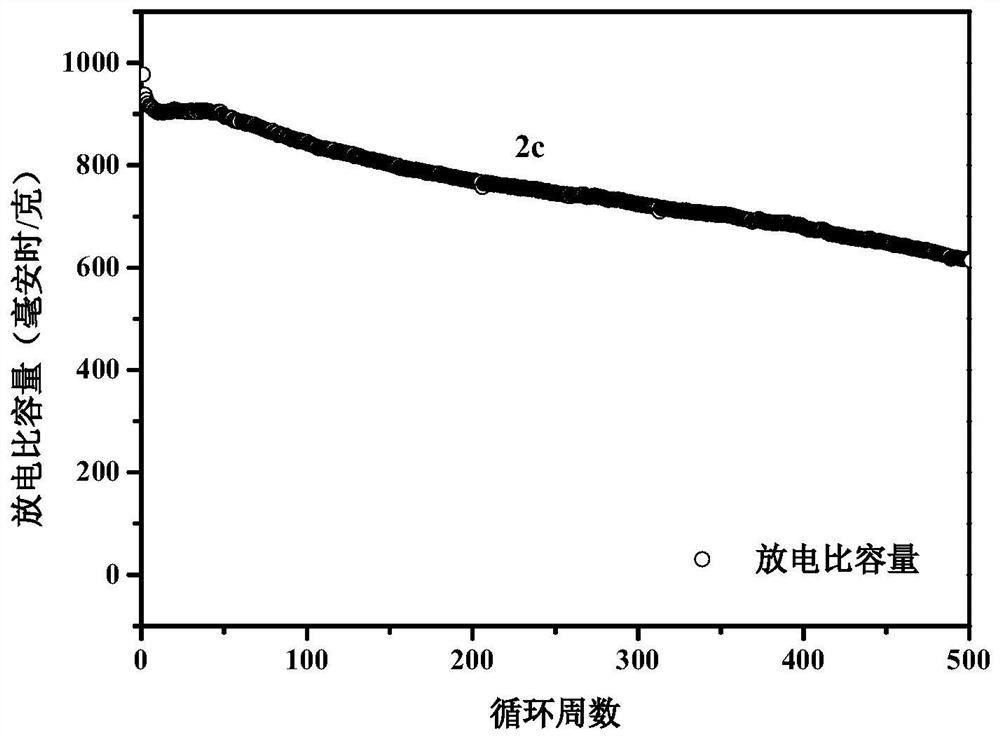

Embodiment 2

[0060] (1) Electrolytic manganese dioxide, lithium nitrate and ammonium molybdate tetrahydrate were ball milled for 2 hours for the first mixing (wherein, the molar ratio of Mn:Li:Mo was 3:1:0.2), and then the obtained first mixture was placed Carry out the first sintering in a tube furnace: raise the temperature to 250°C at a rate of 5°C / min in an argon atmosphere, and keep it for 2 hours; then continue to raise the temperature to 350°C, and keep it for 6 hours; finally lower it to room temperature to obtain the carrier Z2; Among them, the molar ratio of manganese, lithium and molybdenum in Z2 is 3:1:0.2;

[0061] (2) The carrier Z2 and nano-sulfur powder are ball milled for 2 hours at a mass ratio of 3:7 for the second mixing, and then the second mixture obtained is placed in a polytetrafluoroethylene reactor for sealing under an argon atmosphere, and placed in a vacuum Carry out the second sintering in an oven: the sintering temperature is 155°C, the time is 24h, and after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com