Spinel-structure-based high-entropy ceramic material as well as preparation method and application thereof

A spinel structure, ceramic material technology, applied in structural parts, electrical components, battery electrodes, etc., can solve problems such as sparse reports and unclear scientific issues, and achieve cogeneration, high energy conversion efficiency, and battery performance. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A method for preparing the above-described high-entropy ceramic material based on spinel structure, comprising the following steps:

[0036] S1. Press MnCo x (Ca y Cr y Fe y Ni y Zn y )O 4 The stoichiometric ratio of the chemical reaction is used to prepare the metal salt solution, and then the complexing agent is added according to the preset molar ratio, the pH value is adjusted to 7-8, and the water is gradually evaporated by heating to obtain the precursor;

[0037] Specifically will (CH 3 COO) 2 Mn, Co(NO 3 ) 3 , CaCO 3 (Add a certain amount of nitric acid to dissolve), Cr(NO 3 ) 3 , Fe(NO 3 ) 3 , Ni(NO 3 ) 2 , Zn(NO 3 ) 2 by MnCo 1.8 (Ca 0.04 Cr 0.04 Fe 0.04 Ni 0.04 Zn 0.04 )O 4 The stoichiometric ratio was dissolved in deionized water, and citric acid and ethylenediaminetetraacetic acid were added as complexing agents according to 1.5 times and 1 times the molar weight of metal ions, and ammonia water was added to adjust the pH value to 7...

Embodiment 1-5

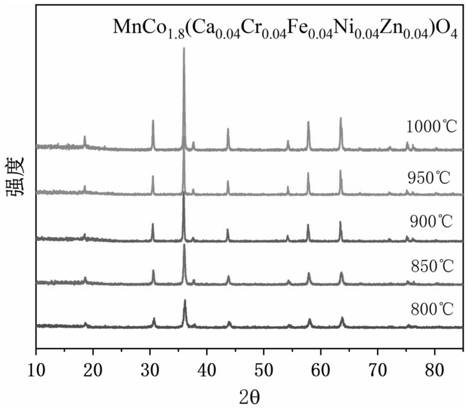

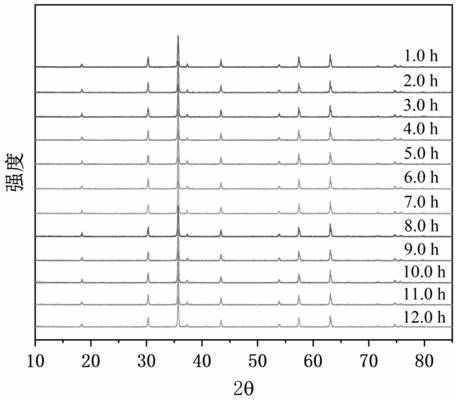

[0042] The chemical formula of the high-entropy ceramic material based on the spinel structure provided by Examples 1-5 is MnCo 1.8 (Ca 0.04 Cr 0.04 Fe 0.04 Ni 0.04 Zn 0.04 )O 4 , prepared by:

[0043] Will (CH 3 COO) 2 Mn, Co(NO 3 ) 3 , CaCO 3 , Cr(NO 3 ) 3 , Fe(NO 3 ) 3 , Ni(NO 3 ) 2 , Zn(NO 3 ) 2 by MnCo 1.8 (Ca 0.04 Cr 0.04 Fe 0.04 Ni 0.04 Zn 0.04 )O 4 The stoichiometric ratio is added to the deionized aqueous solution in sequence; then, citric acid is added according to 1.5 times the molar weight of metal ions, ethylenediaminetetraacetic acid is added in an amount of 1 times the molar weight of metal ions, ammonia water is added, and the pH value is adjusted to 7-8 , keep the aqueous solution clear. Heat it on a magnetic stirrer to evaporate the moisture, continue to heat after evaporation to make it gel and gradually generate a precursor; then respectively at 800°C (Example 1), 850°C (Example 2), 900°C ℃ (embodiment 3), 950 ℃ (embodiment 4), 10...

Embodiment 6

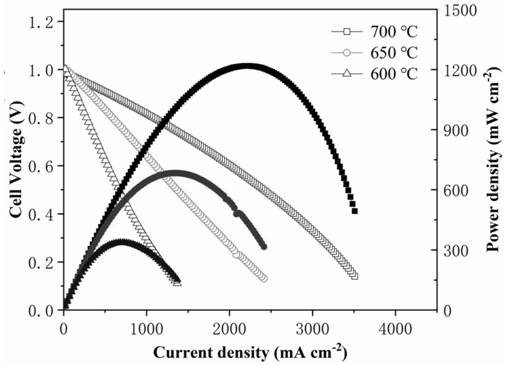

[0047] The novel high entropy ceramic material of the present embodiment, its concrete chemical composition is MnCo 1.8 (Ca 0.04 Cr 0.04 Fe 0.04 Ni 0.04 Zn 0.04 )O 4 , using it as the cathode, NiO-BCZY as the anode support, and BCZY as the electrolyte to form a full battery for electrochemical performance testing. Its assembly method is carried out according to the following steps:

[0048] (1) Fe(NO 3 ) 3 , (CH 3 COO) 2 Mn, Co(NO 3 ) 3 , CaCO 3 , Ni(NO 3 ) 2 , Cr(NO 3 ) 3 , Zn(NO 3 ) 2 by MnCo 1.8 (Ca 0.04 Cr 0.04 Fe 0.04 Ni 0.04 Zn 0.04 )O 4The stoichiometric ratio is mixed evenly, and citric acid and ethylenediaminetetraacetic acid are respectively added as complexing agents according to 1.5 times and 1 times the molar weight of metal ions, and then ammonia water is added to adjust the pH=7-8. After the solution was stirred for 5 h, it was heated on a magnetic stirrer and evaporated to dryness. After evaporation to dryness, it was heated continuous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com