Preparation method of saturable absorber based on WS2

A saturable absorption, sapphire substrate technology, applied in the field of preparation of practical saturable absorbers based on transition metal sulfides, can solve the problems of uncontrollable distribution of nanosheets, complicated preparation process, high experimental requirements, etc., to achieve improved resistance to laser damage Threshold, reduce overlap area, increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to illustrate the technical solution of the present invention more clearly, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

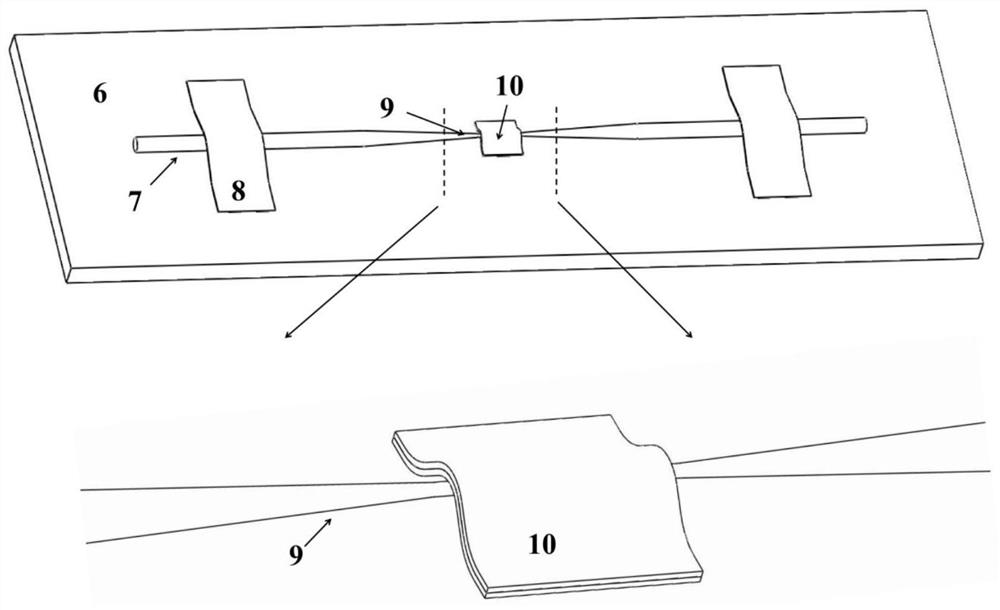

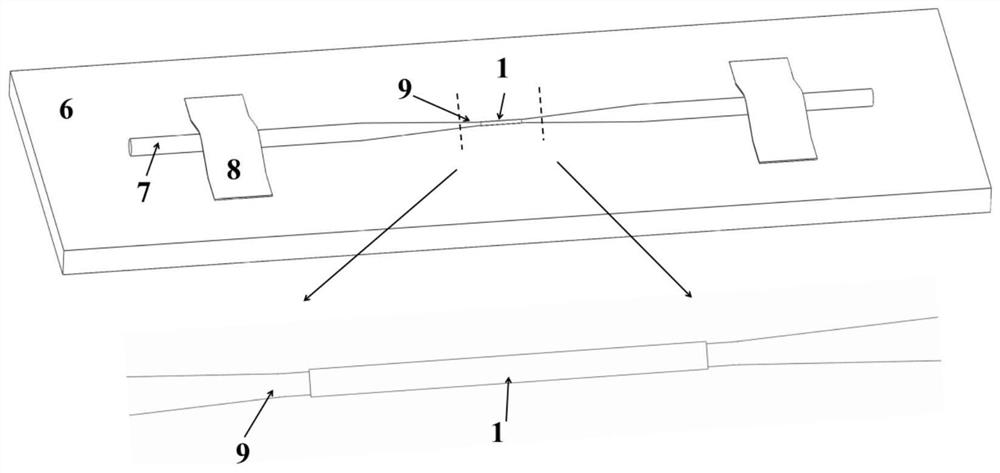

[0042] The WS 2 The steps of the preparation method of the film-wrapped micro-optical fiber saturable absorber are as follows:

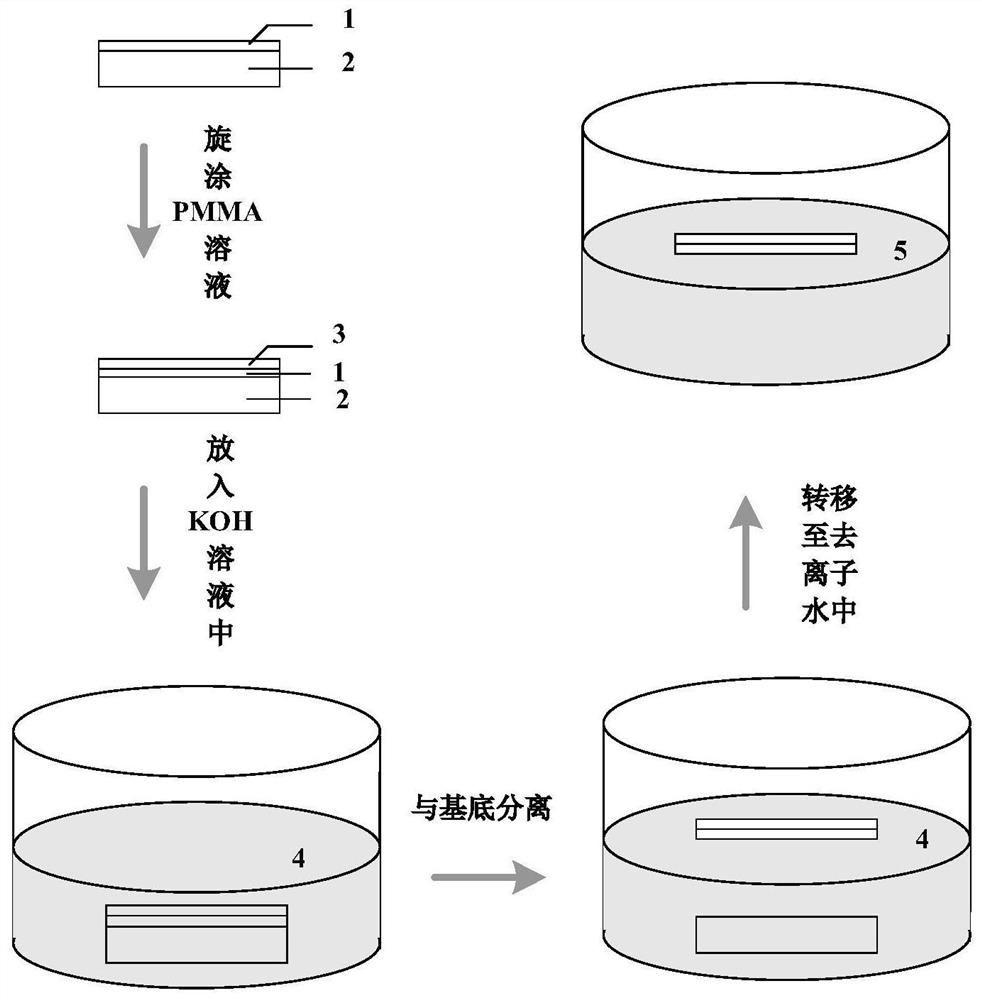

[0043] 1) Preparation of WS 2 / PMMA film

[0044] Such as figure 1 As shown, the sapphire substrate 2 (size 10×0.2mm 2 ) on WS 2 Film Sample 1, at WS 2 Spin-coat a layer of polymethyl methacrylate (PMMA) solution on the surface of the film sample; place it at room temperature for 4 hours to solidify the PMMA into a film, forming a three-layer layered structure of sapphire / WS 2 / PMMA sample, PMMA film 3 as a protective medium to prevent WS 2 Film 1 was damaged during subsequent processing; the sapphire / WS 2 / PMMA sample was placed in potassium hydroxide KOH solution 4, placed at room temperature for 24 hours, and then the sapp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com