Preparation method of photocatalytic composite porous membrane

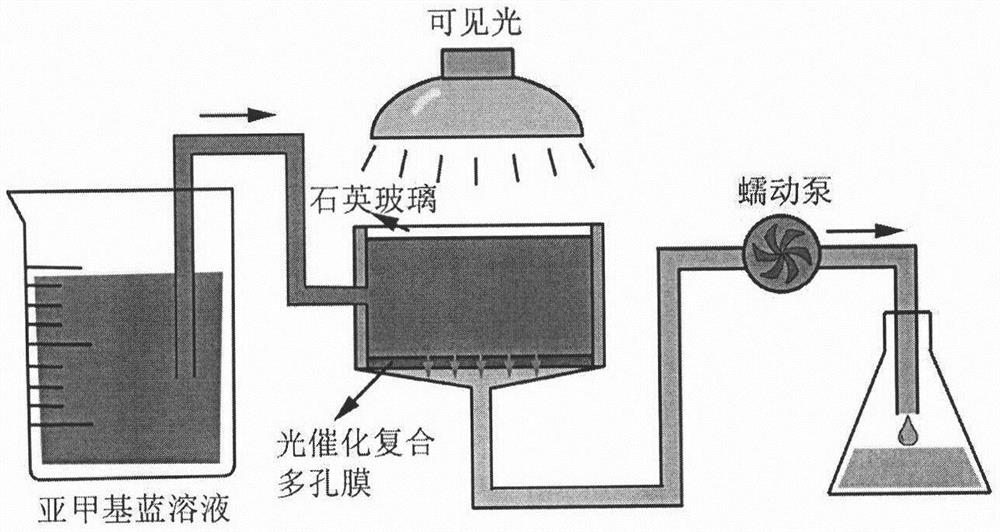

A porous membrane and photocatalytic technology, applied in the field of membrane materials, can solve problems such as limited effect, membrane pollution, and inability to degrade pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023]A preparation method of a photocatalytic composite porous membrane, comprising the following steps:

[0024] 1) Preparation of polyethersulfone porous base membrane: Mix 13wt.% polyethersulfone, 10wt.% polyvinylpyrrolidone and 77wt.% dimethylacetamide, heat to 75°C in a water bath and continue to stir for 6h, then scrape and coat. The film is cured in a deionized water coagulation bath, and the porous film I is obtained after drying at room temperature;

[0025] 2) The porous membrane I obtained in step 1) is immersed in 0.1M cadmium chloride solution, deionized water, 0.1M ammonium sulfide solution, deionized water successively, and a dipping cycle is completed, which is called cycle A. A was repeated 10 times to synthesize cadmium sulfide on the surface of porous film I to obtain porous film II;

[0026] 3) The porous membrane II obtained in step 2) was immersed in a 0.1M ferric nitrate solution for 2 minutes, and then immersed in a 0.1M pyrrole solution for 2 minutes...

Embodiment 2

[0029] 1) Preparation of polyethersulfone porous base film: Mix 15wt.% polyethersulfone, 10wt.% polyvinylpyrrolidone and 75wt.% dimethylacetamide, heat to 75°C in a water bath and continue stirring for 6h, scrape and coat The film is cured in a deionized water coagulation bath, and the porous film I is obtained after drying at room temperature;

[0030] 2) The porous membrane I obtained in step 1) is immersed in 0.1M cadmium chloride solution, deionized water, 0.1M ammonium sulfide solution, deionized water successively, and a dipping cycle is completed, which is called cycle A. A was repeated 10 times to synthesize cadmium sulfide on the surface of porous film I to obtain porous film II;

[0031] 3) The porous membrane II obtained in step 2) was immersed in a 0.1M ferric nitrate solution for 2 minutes, and then immersed in a 0.1M pyrrole solution for 2 minutes to synthesize polypyrrole to obtain a photocatalytic composite porous membrane.

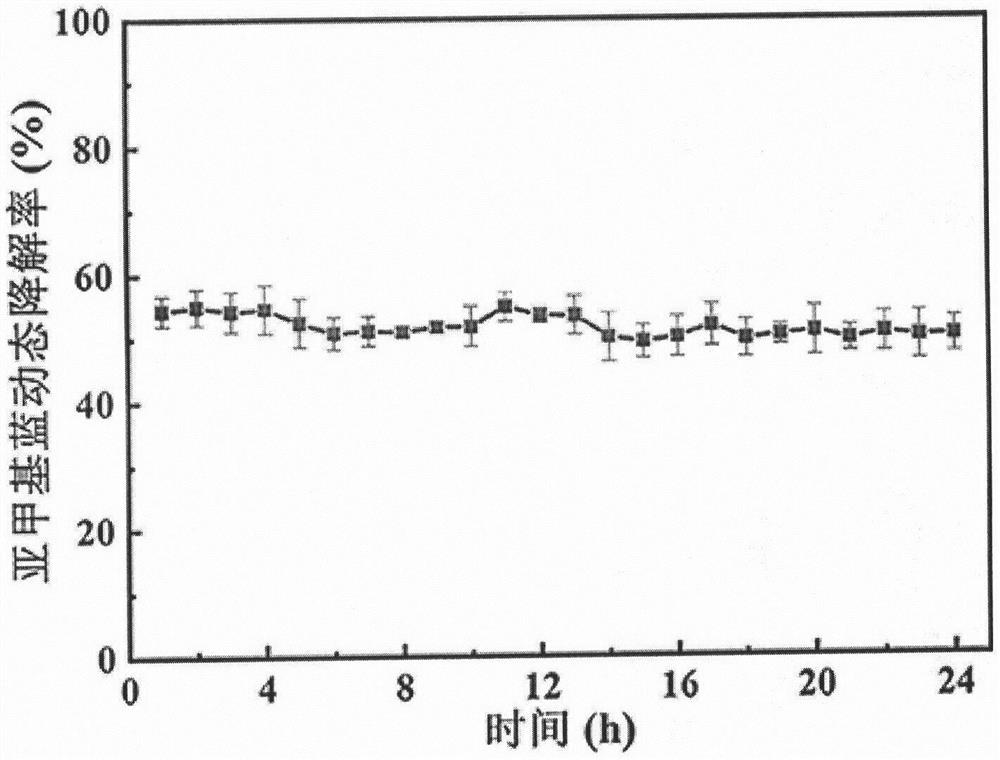

[0032] In this example, the produc...

Embodiment 3

[0034] 1) Preparation of polyethersulfone porous base membrane: Mix 13wt.% polyethersulfone, 10wt.% polyvinylpyrrolidone and 77wt.% dimethylacetamide, heat to 75°C in a water bath and continue to stir for 6h, then scrape and coat. The film is cured in a deionized water coagulation bath, and the porous film I is obtained after drying at room temperature;

[0035] 2) the porous membrane I obtained in step 1) is successively dipped in 0.1M cadmium nitrate solution, deionized water, 0.1M ammonium sulfide solution, deionized water to complete a dipping cycle, called cycle A, and cycle A is Repeat 10 times to synthesize cadmium sulfide on the surface of porous membrane I to obtain porous membrane II;

[0036] 3) The porous membrane II obtained in step 2) was immersed in a 0.1M ferric nitrate solution for 2 minutes, and then immersed in a 0.1M pyrrole solution for 2 minutes to synthesize polypyrrole to obtain a photocatalytic composite porous membrane.

[0037] In this example, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com