FexP/Mn0. 3Cd0.7S composite photocatalyst, and preparation method and application thereof

A catalyst and composite light technology, applied in physical/chemical process catalysts, chemical instruments and methods, hydrogen/syngas production, etc., can solve the problems of poor stability and high toxicity of phosphide, achieve rich content and inhibit photocorrosion phenomenon , The effect of excellent hydrogen production stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of Fe x P / Mn 0.3 Cd 0.7 The preparation method of S composite photocatalyst includes the following steps:

[0046] (1) Put 500mg of Mn 0.3 Cd 0.7 The S catalyst was added to 50mL ethanolamine solvent, stirred uniformly, and then dispersed uniformly by ultrasonic to obtain a suspension;

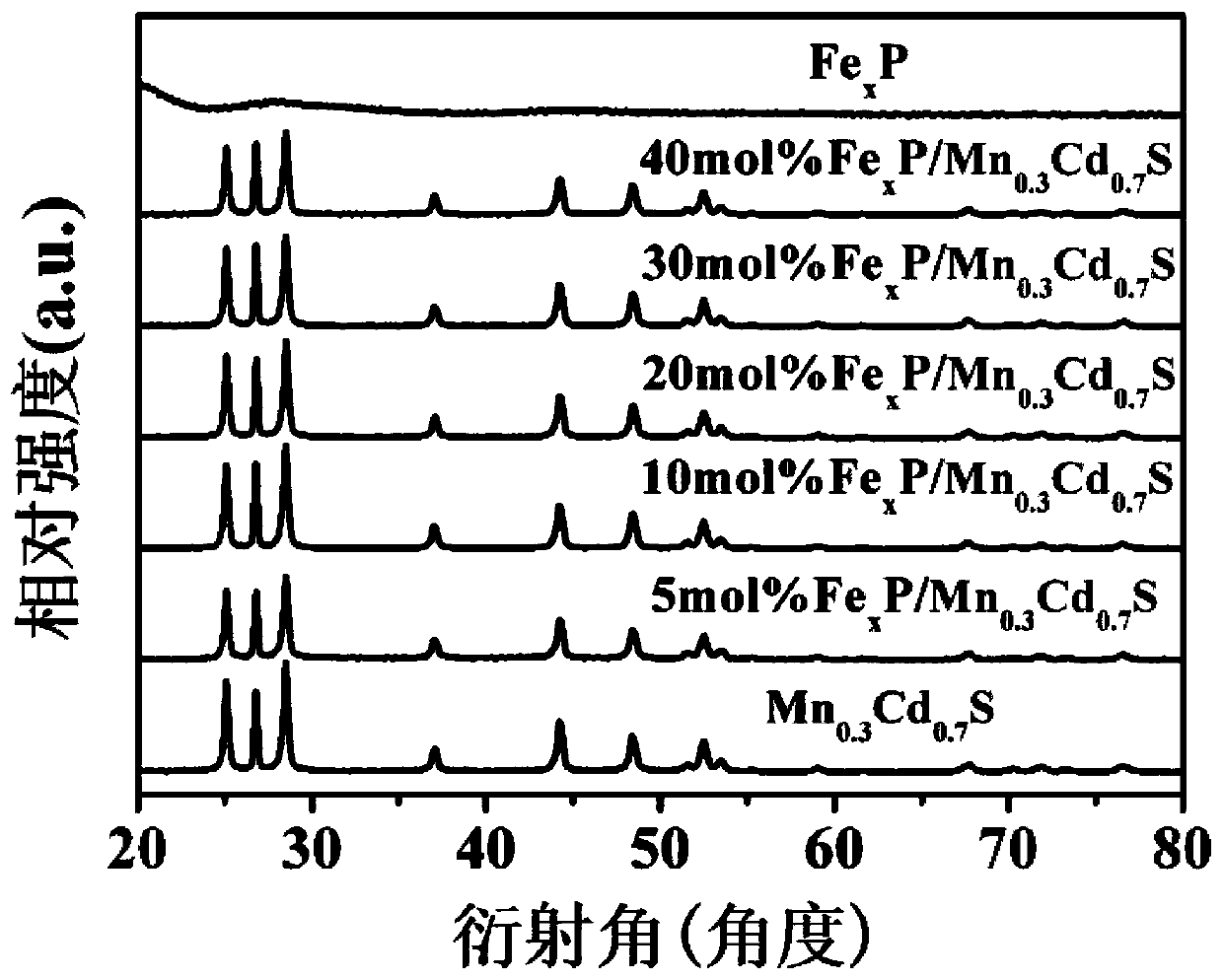

[0047] (2) Put 54mg of FeCl under stirring 3 ·6H 2 O and 25mg of pretreated red phosphorus were added to the suspension described in step (1), stirred uniformly, dispersed uniformly by ultrasound to form a uniformly dispersed suspension; then transferred and sealed in a reactor equipped with a polytetrafluoroethylene liner , Heat up to 180℃ for solvothermal reaction, the time of solvothermal reaction is 12h, cool to room temperature, filter the precipitate, wash and dry to obtain Fe x P and Mn 0.3 Cd 0.7 The molar ratio of S is 5mol% Fe x P / Mn 0.3 Cd 0.7 S composite photocatalyst, labeled as 5mol% Fe x P / Mn 0.3 Cd 0.7 S.

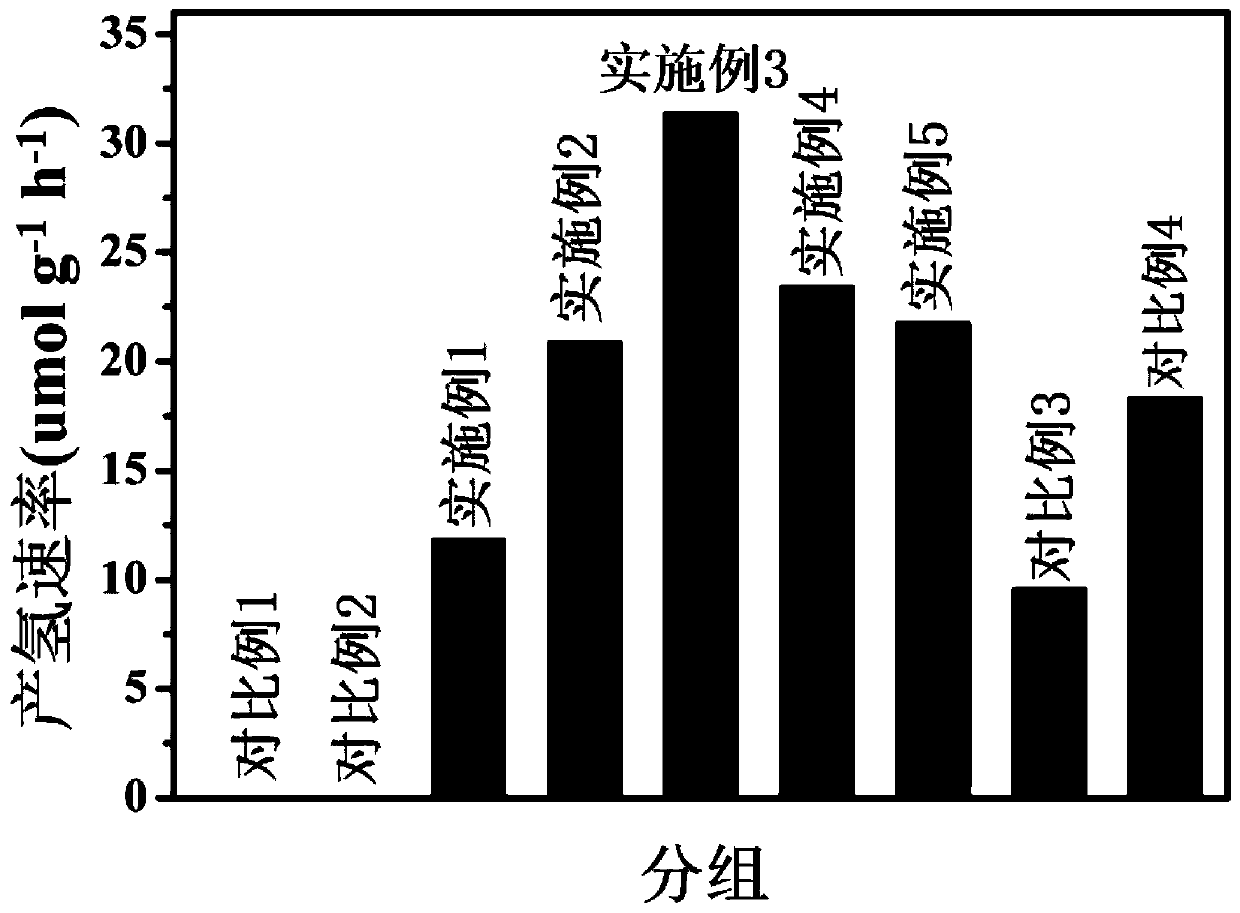

[0048] Performance test: under the irradiation of 300W Xe lamp, ...

Embodiment 2

[0050] A kind of Fe x P / Mn 0.3 Cd 0.7 The preparation method of S composite photocatalyst includes the following steps:

[0051] (1) Put 500mg of Mn 0.3 Cd 0.7 The S catalyst was added to 50mL ethanolamine solvent, stirred uniformly, and then dispersed uniformly by ultrasonic to obtain a suspension;

[0052] (2) Add 107mg of FeCl under stirring 3 ·6H 2 O and 49 mg of the pretreated red phosphorus were added to the suspension described in step (1), stirred uniformly, and dispersed uniformly by ultrasound to form a uniformly dispersed suspension. Then it was transferred and sealed in a reactor equipped with a polytetrafluoroethylene liner. The temperature was raised to 180°C for solvothermal reaction. The solvothermal reaction time was 12h, cooled to room temperature, filtered, washed, and dried to obtain Fe x P and Mn 0.3 Cd 0.7 The molar ratio of S is 10mol% Fe x P / Mn 0.3 Cd 0.7 S composite photocatalyst, labeled as 10mol% Fe x P / Mn 0.3 Cd 0.7 S.

[0053] Performance test: Under the ...

Embodiment 3

[0055] A kind of Fe x P / Mn 0.3 Cd 0.7 The preparation method of S composite photocatalyst includes the following steps:

[0056] (1) Put 500mg of Mn 0.3 Cd 0.7 S catalyst was added to 50mL ethanolamine solvent, stirred uniformly, and then dispersed uniformly by ultrasonic to obtain a suspension;

[0057] (2) Add 213mg of FeCl under stirring 3 ·6H 2 O and 98 mg of pretreated red phosphorus were added to the suspension described in step (1), stirred uniformly, and dispersed uniformly by ultrasonic to form a uniformly dispersed suspension; then transferred and sealed in a reactor equipped with a polytetrafluoroethylene liner , Heat up to 180℃ for solvothermal reaction, the time of solvothermal reaction is 12h, cool to room temperature, filter the precipitate, wash, and dry to obtain Fe x P and Mn 0.3 Cd 0.7 The molar ratio of S is 20mol% Fe x P / Mn 0.3 Cd 0.7 S composite photocatalyst, labeled as 20mol% Fe x P / Mn 0.3 Cd 0.7 S.

[0058] Performance test: under the irradiation of 300W Xe l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com