Ultrathin CaIn2S4 nanosheet photocatalytic material and preparation method thereof

A photocatalytic material, cain2s4 technology, applied in the field of ultra-thin CaIn2S4 nanosheet photocatalytic materials and their preparation, can solve problems such as excellent sterilization performance, achieve the effects of simple process, improved photocatalytic sterilization efficiency, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

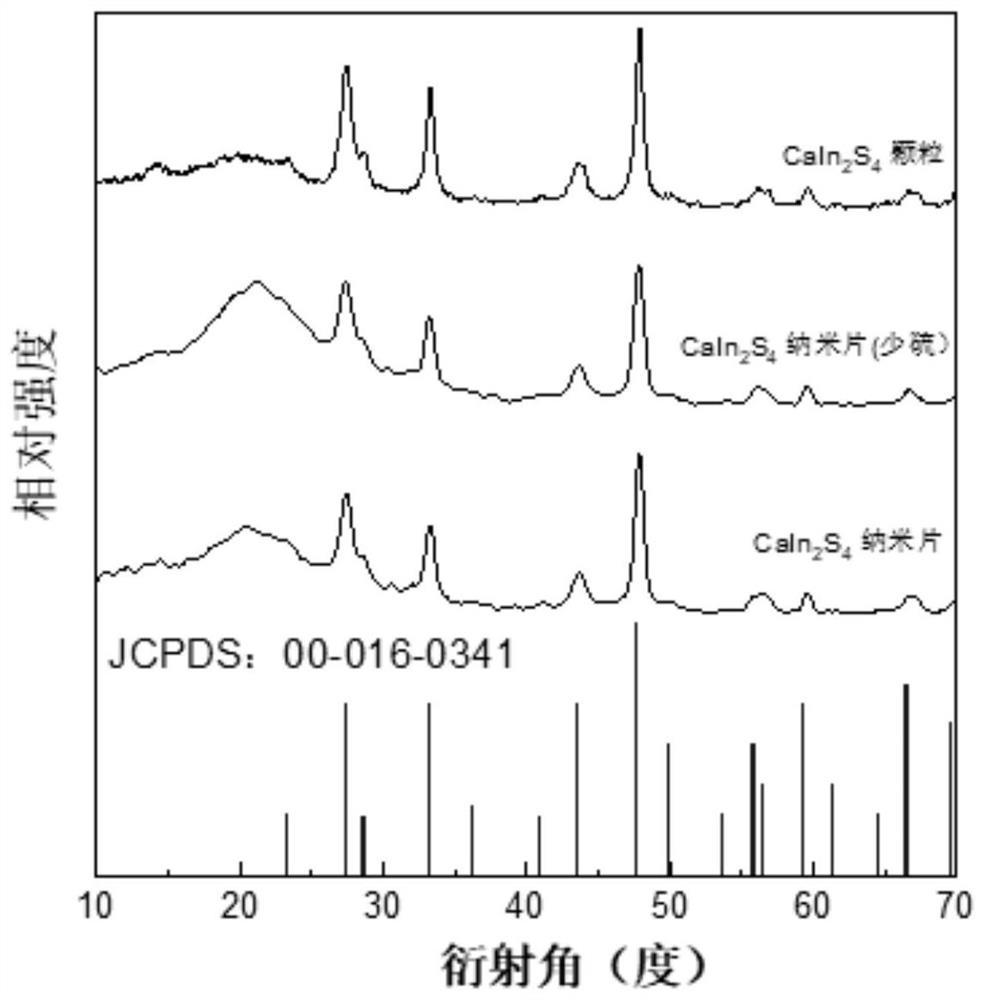

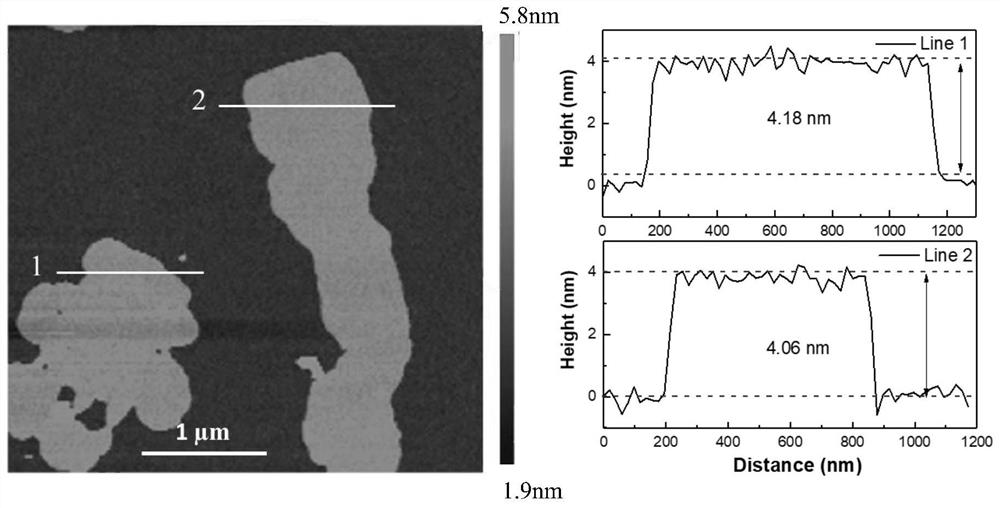

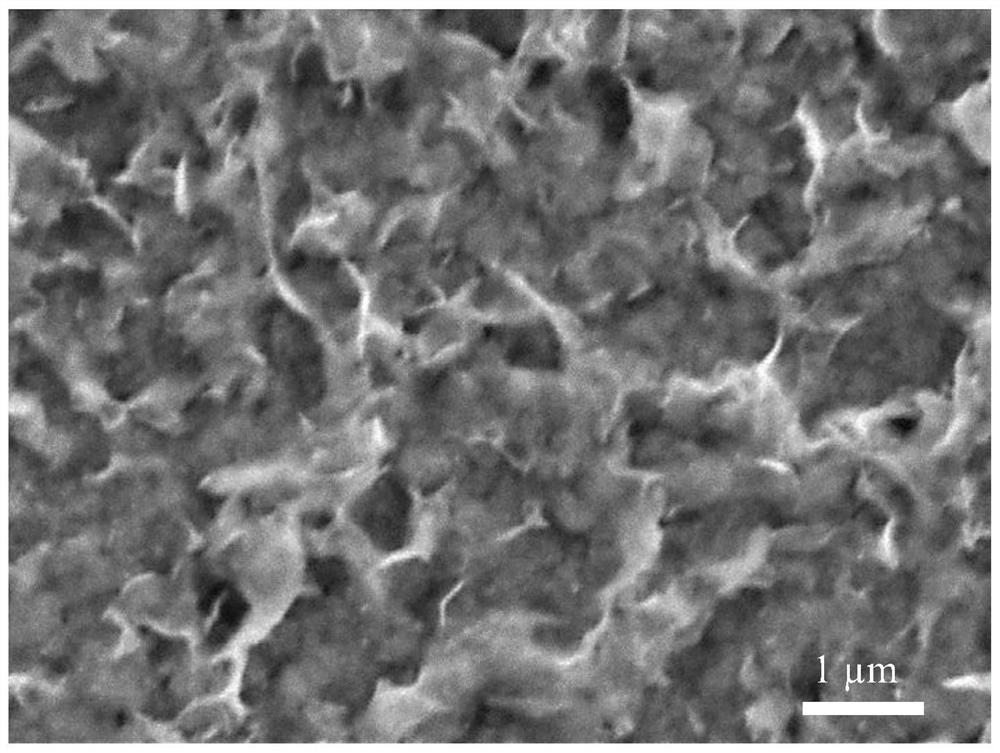

[0036] Embodiment 1 Ultra-thin CaIn of the present invention 2 S 4 Preparation of Nanosheets (1)

[0037] Dissolve 0.2643g of calcium acetate monohydrate and 0.6635g of anhydrous indium chloride in a round bottom flask filled with 250mL of deionized water, stir at room temperature for 30min, then add 0.6010g of thioacetamide and stir until dissolved, then place the round Put the bottom flask into an oil bath and heat up to 95°C, and stir vigorously for 5 hours. The resulting suspension was centrifuged at a speed of 9000r.p.m. for 3min, the precipitate was collected and washed twice with deionized water, dispersed again in 200mL of deionized water, ultrasonically stripped at 40KHz, 250W for 30min, and then centrifuged at a speed of 6000r.p.m. for 5min, and taken The supernatant was used as a sample.

Embodiment 2

[0038] Embodiment 2 Ultra-thin CaIn of the present invention 2 S 4 Preparation of Nanosheets (2)

[0039] Dissolve 0.2643g of calcium acetate monohydrate and 0.6635g of anhydrous indium chloride in a round bottom flask filled with 250mL of deionized water, stir at room temperature for 30min, then add 0.7892g of thioacetamide and stir until dissolved, then place the round Put the bottom flask into an oil bath and heat up to 95°C, and stir vigorously for 5 hours. The resulting suspension was centrifuged at a speed of 9000r.p.m. for 3min, the precipitate was collected and washed twice with deionized water, dispersed again in 200mL of deionized water, ultrasonically stripped at 40KHz, 250W for 30min, and then centrifuged at a speed of 6000r.p.m. for 5min, and taken The supernatant was used as a sample.

Embodiment 3

[0040] Embodiment 3 Ultra-thin CaIn of the present invention 2 S 4 Preparation of Nanosheets (3)

[0041]Dissolve 0.2643g of calcium acetate monohydrate and 0.6635g of anhydrous indium chloride in a round bottom flask filled with 250mL of deionized water, stir at room temperature for 30min, then add 0.6010g of thioacetamide and stir until dissolved, then place the round Put the bottom flask into an oil bath and heat up to 95°C, and stir vigorously for 5 hours. The resulting suspension was centrifuged at a speed of 9000r.p.m. for 3min, the precipitate was collected and washed twice with deionized water, dispersed in 200mL of deionized water again, ultrasonically stripped at 40KHz and 300W for 30min, and then centrifuged at a speed of 6000r.p.m. for 5min, and the The supernatant was used as a sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com