Genetically engineered bacterium for increasing butanedione content and acetoin content in yoghourt and application thereof

A technology of genetically engineered bacteria and diacetyl, applied in genetic engineering, bacteria used in food preparation, applications, etc., can solve problems such as low yield and difficulty in satisfying the flavor of yogurt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

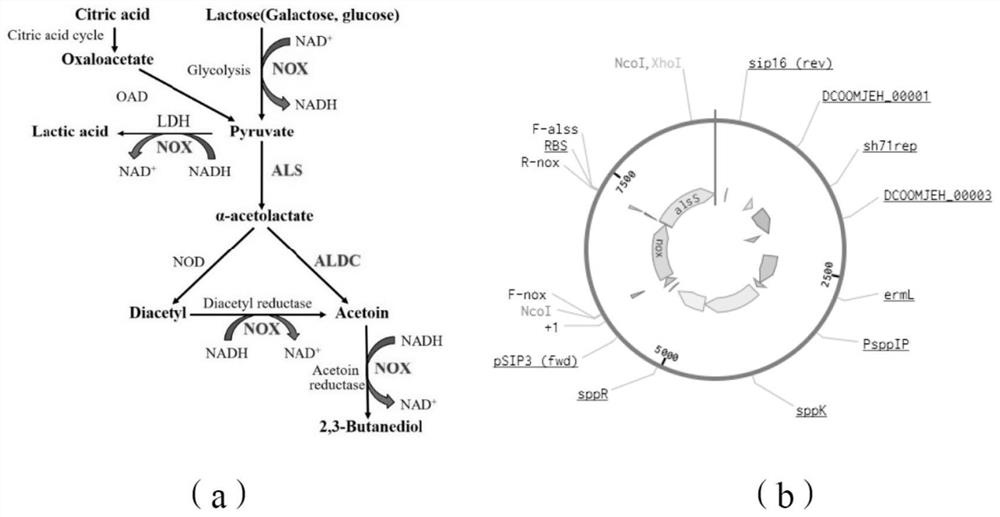

[0020] Construction of engineering bacteria producing diacetyl and acetoin:

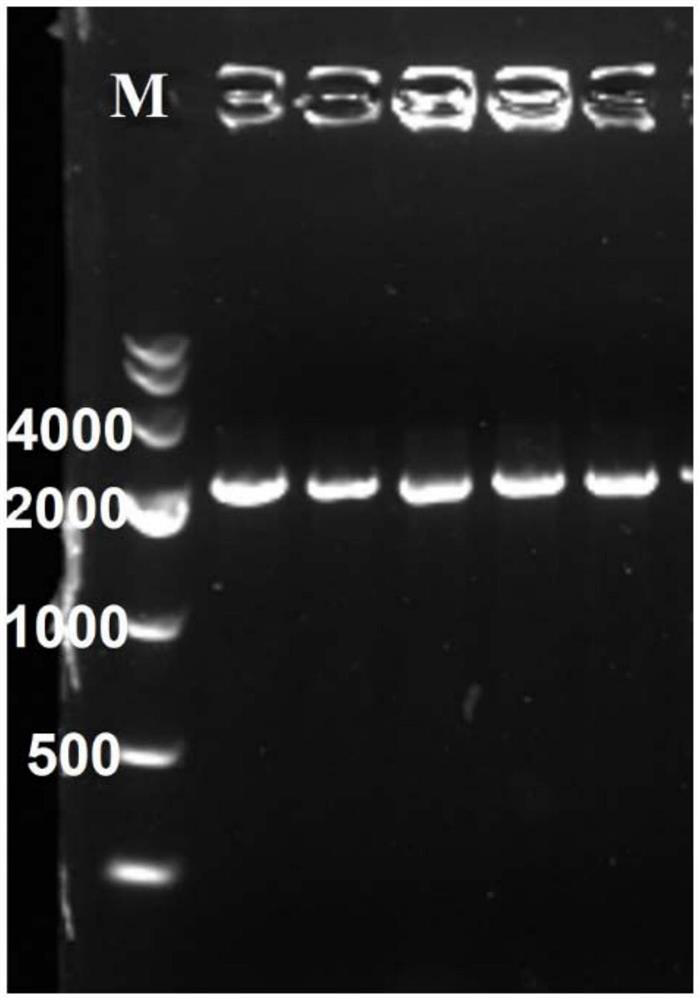

[0021] 1. Construction of expression vector pSIP409-nox-alsS

[0022] According to the nox gene sequence of Streptococcus mutans and the alsS gene sequence in the whole genome of Lactobacillus casei TCS, in order to co-express the nox and alsS genes in a single vector, a ribosome binding site was added to the 5' end of the alsS gene, using Premier 5.0 and Vector NTI software designed primers nox-F, nox-R and alsS-F, alsS-R, and used the one-step cloning kit to connect the nox and alsS fragments to the vector pSIP409. The NcoI restriction site was introduced at the 5' end of the primer nox-F, and the XhoI restriction site was introduced at the 5' end of the primer alsS-R. After the PCR product was purified, it was ligated with the expression vector pSIP409, which was double-digested with the same restriction site, transformed into E.coli DH5α competent cells (VazymeBiotech Co., Ltd., Nanjing, China),...

Embodiment 2

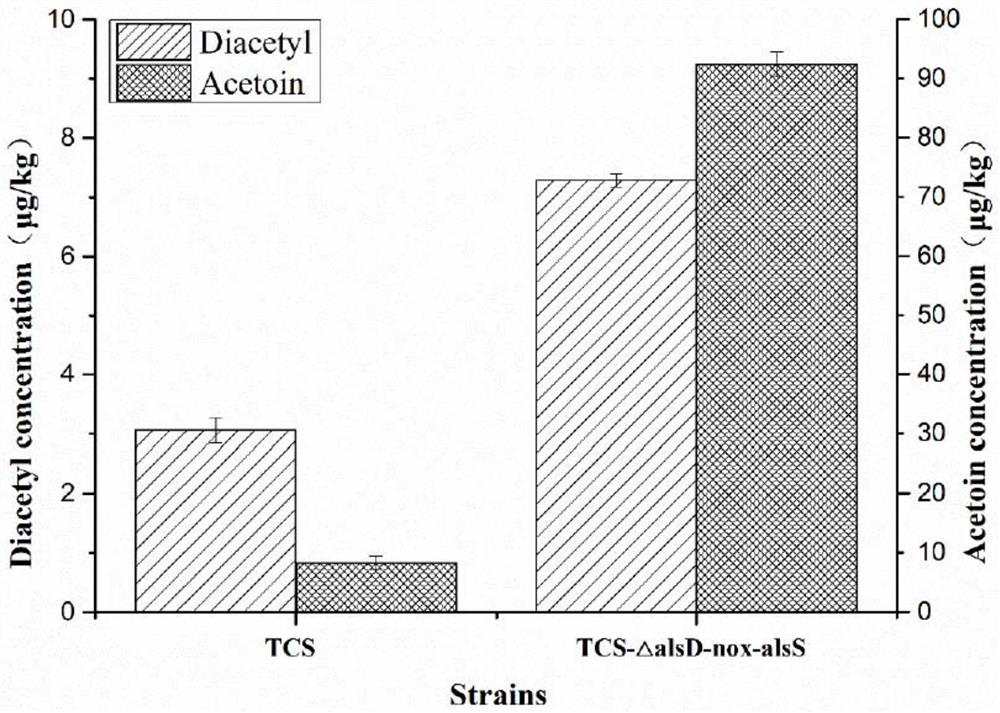

[0031] Yogurt fermented by wild-type strain TCS and engineered strain TCS-ΔalsD-nox-alsS:

[0032] Inoculate the to-be-used TCS and TCS-ΔalsD-nox-alsS strains in MRS broth respectively, culture them conventionally at 37°C for 12-16 hours, collect the bacteria by centrifugation at 6000×g for 10 minutes at room temperature, wash them twice with sterile water, and use An equal volume of sterile water was resuspended, and the suspension was used as a starter culture. Use 12% (w / v) skimmed milk powder to prepare yogurt, sterilize at 95°C for 10 minutes, wait until the sterilized skim milk is cooled to about 40°C, and inoculate the bacteria suspension obtained above at a ratio of 4% (v / v). Bacteria skim milk, and IP-673 with a final concentration of 25ng / mL was added to the inducible recombinant bacterium TCS-ΔalsD-nox-alsS for induction. After that, it was left to ferment at 37° C. until the pH was about 4.6, and then placed in a refrigerator at 4° C. for 12-24 hours after ripenin...

Embodiment 3

[0034] Enzyme Activity Determination of Engineering Bacteria:

[0035] The enzyme activities of the wild strain TCS and the engineered strain TCS-ΔalsD-nox-alsS were determined, and the enzyme activities of NADH oxidase and α-acetolactate synthase were determined respectively.

[0036](1) Determination of NADH oxidase activity: NOX activity was determined using NADH oxidase activity detection kit (Solarbio Science & Technology, Beijing, China). The enzyme activity unit (U) is defined as every 10,000 bacteria in the reaction system, and the A600 change of 0.01 per minute in the reaction system is defined as an enzyme activity unit.

[0037] (2) Assay of α-acetolactate synthase activity: ALS activity was determined according to the method described by Holtzclaw (Holtzclaw and Chapman 1975) with some modifications. In 1mM thiamine pyrophosphate, 5mM MgCl 2 , 0.1mM flavin adenine dinucleotide, 100mM sodium pyruvate and 300μL crude enzyme solution. The reaction was carried out a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com