Polysaccharide nanofilm and preparation method thereof

A nano-membrane and polysaccharide technology, which is applied in the manufacture of rayon, textiles and paper, and conjugated synthetic polymer artificial filaments. It can solve the problems of poor fresh-keeping effect of nano-membranes, reduced antibacterial and anti-oxidative effects, and poor film-forming properties. problems, to achieve the effect of improving antibacterial, anti-corrosion, fresh-keeping and anti-oxidation effects, promoting comprehensive development and utilization, and delaying oxidative decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

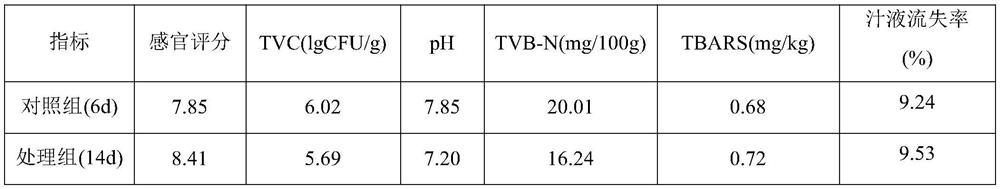

Examples

preparation example Construction

[0045] The invention provides a polysaccharide nano-membrane based on plant essential oils combined with organic acids and a preparation method thereof, wherein the preparation method comprises:

[0046] Preparation of plant essential oil / cyclodextrin inclusion compound: mix plant essential oil with cyclodextrin aqueous solution, and precipitate crystals to obtain plant essential oil / cyclodextrin inclusion compound;

[0047] Preparation of the first spinning solution: mixing the chitosan acetic acid aqueous solution and the polysaccharide to form a first mixture, mixing the first mixture with the spinning solution to obtain the first spinning solution;

[0048] Preparation of the second spinning solution: mixing an organic acid as a functional additive raw material with the first spinning solution to obtain a second spinning solution;

[0049] Preparation of nano-membrane: the second spinning solution is mixed with plant essential oil / cyclodextrin inclusion compound, and the n...

Embodiment 1

[0066] A polysaccharide nanofilm

[0067] Add 19g of cyclodextrin to 1kg of double-distilled water at 45°C to prepare cyclodextrin aqueous solution; take 1kg of cyclodextrin aqueous solution and 0.05kg of plant essential oil and mix (the mixing method adopts constant temperature stirring, and the temperature of stirring is 40 ℃, the time of stirring is 2h), crystals are precipitated at a temperature of 2 ℃, after the crystals are precipitated, suction filtration is obtained, and the filter residue is freeze-dried to obtain the plant essential oil / cyclodextrin inclusion complex; polyvinyl alcohol and Water was mixed under a water bath at 75°C at a volume ratio of 1:10 to obtain a spinning solution; chitosan was mixed with 2% acetic acid aqueous solution at a volume ratio of 1:40, and stirred electrically until dissolved (the chitosan The mass concentration of acetic acid aqueous solution is 2.5%), obtains chitosan acetic acid aqueous solution; Said chitosan acetic acid aqueous ...

Embodiment 2

[0069] A polysaccharide nanofilm

[0070] Add 19g of cyclodextrin to 1kg of double-distilled water at 50°C to prepare cyclodextrin aqueous solution; take 1kg of cyclodextrin aqueous solution and 0.1kg of plant essential oil and mix (the mixing method adopts constant temperature stirring, and the temperature of stirring is 50 ℃, the time of stirring is 2.5h), crystals are precipitated at a temperature of 4 ℃, after the crystals are precipitated, they are suction filtered, and the filter residue is freeze-dried to obtain the plant essential oil / cyclodextrin inclusion complex; the polyvinyl alcohol Mix with water at a volume ratio of 1:12 under a water bath at 80°C to obtain a spinning solution; mix chitosan with 2% acetic acid aqueous solution at a volume ratio of 1:60, and stir until dissolved (the chitosan The mass concentration of sugar acetic acid aqueous solution is 1.7%), obtains chitosan acetic acid aqueous solution, the chitosan acetic acid aqueous solution and the polys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com