High-lipid digestibility concentrated emulsion containing low-concentration vegetable phospholipids

A plant phospholipid and concentrated milk technology, applied in dairy products, milk preparations, applications, etc., can solve problems such as long gastric emptying time and slow lipid enzymatic hydrolysis rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0133] The concentrated emulsion prepared by the present invention has the following advantages:

[0134] 1. Using innovative non-high temperature emulsion concentration technology, the concentration process will not have obvious impact on the nutrition, color and flavor of the emulsion.

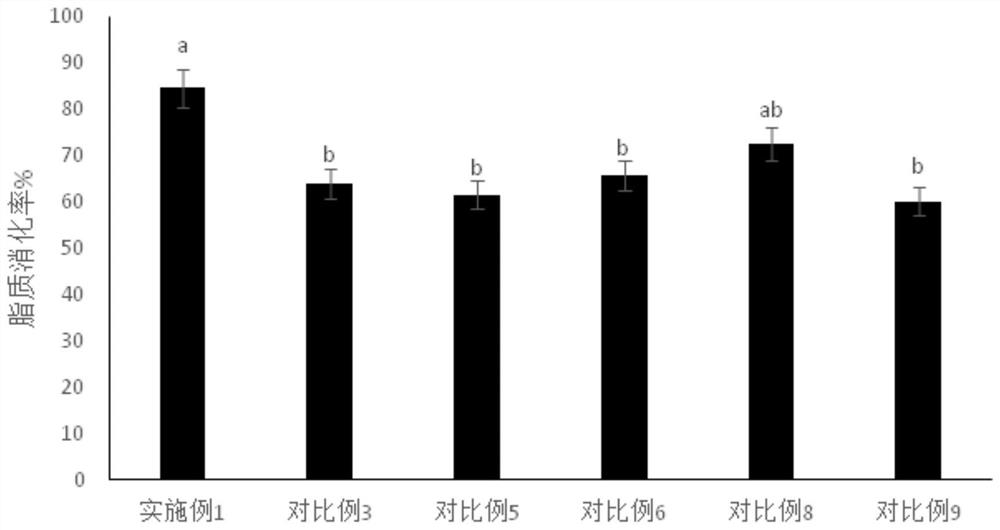

[0135] 2. After special phospholipid, fat ratio and type formula design, the lipid digestion rate of the reconstituted emulsion is higher than that of traditional infant formula milk powder.

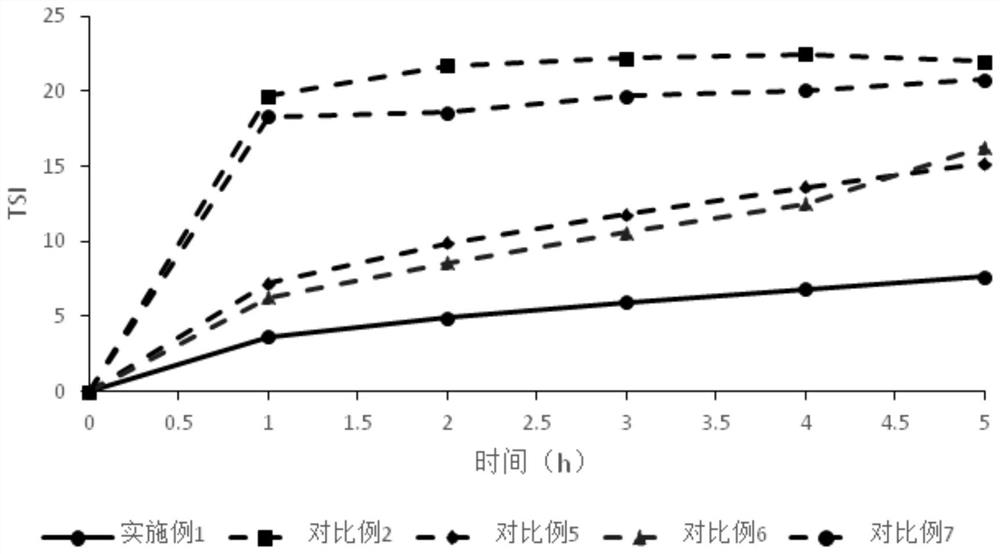

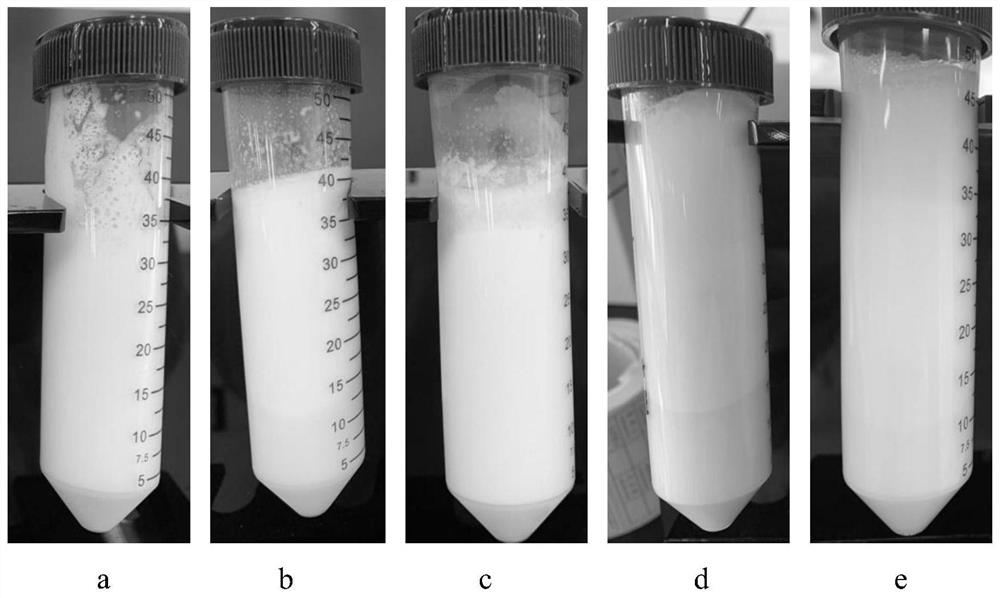

[0136] 3. The concentrated milk of the present invention is stable during the shelf life, and is less prone to problems such as flocculation, stratification, and precipitation during storage.

Embodiment 1

[0151] The formulations of the water and oil phases are shown in Table 1. Emulsion concentrates and infant formula were prepared using the following methods:

[0152] Step (1): Mix coconut oil, rice oil, OPO-55, soybean oil, monoglyceride and algal oil, and stir in a water bath at 60° C. to form an oil phase.

[0153] Step (2): mix sunflower phospholipid and water, and stir in a water bath at 60° C. for 30 minutes to form a phospholipid dispersion.

[0154] Step (3): mixing skimmed milk powder, whey protein concentrate powder, milk sphingomyelin, lactose, locust bean gum and the phospholipid dispersion of step (2), stirring for 1 hour to form an aqueous phase.

[0155] Step (4): the oil phase and the water phase are mixed, and sheared at 3000 rpm for 3 minutes to form a primary emulsion.

[0156] Step (5): Homogenize the primary emulsion at 80 bar for 3 times to obtain an emulsion.

[0157] Step (6): The emulsion is kept in a water bath at 65° C. for 30 minutes for pasteuri...

Embodiment 2

[0161] The formulations of the water and oil phases are shown in Table 1. Emulsion concentrates and infant formula were prepared using the following methods:

[0162] Step (1): mixed coconut oil, rice oil, OPO-55, soybean oil, monoglyceride and algae oil, stirred in a water bath at 60° C. to form an oil phase.

[0163] Step (2): mix sunflower phospholipid and water, and stir in a water bath at 60° C. for 30 minutes to form a phospholipid dispersion.

[0164] Step (3): mixing skimmed milk powder, whey protein concentrate powder, milk sphingomyelin, lactose, locust bean gum and the phospholipid dispersion of step (2), stirring for 1 hour to form an aqueous phase.

[0165] Step (4): the oil phase and the water phase are mixed, and sheared at 3000 rpm for 3 minutes to form a primary emulsion.

[0166] Step (5): Homogenize the primary emulsion at 80 bar for 3 times to obtain an emulsion.

[0167] Step (6): The emulsion is kept in a water bath at 65° C. for 30 minutes for pasteur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com