Capsaicin microcapsule insecticide and preparation method thereof

A technology of microcapsules and capsaicin, applied in pesticides, botanical equipment and methods, biocides, etc., can solve the problems of single core material, no direct effect of wall material, single effect, etc. The effect of reducing the number of applications and reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

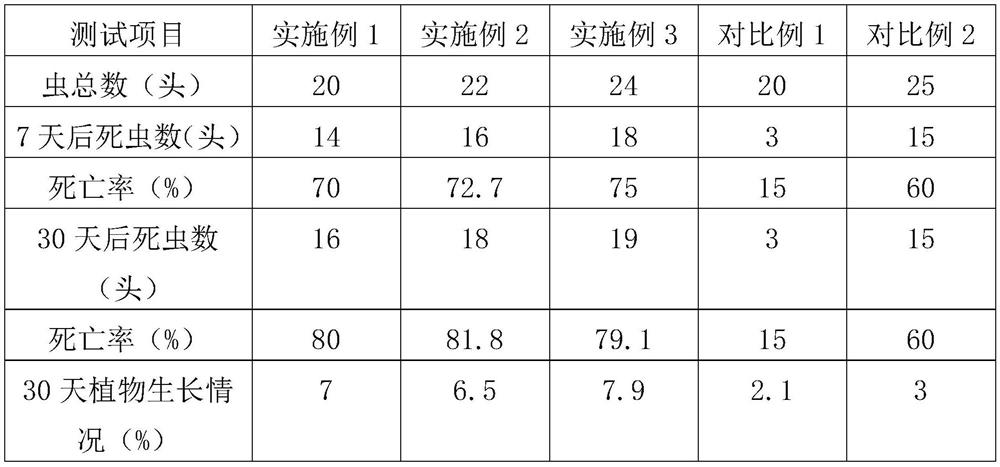

Examples

Embodiment 1

[0031] S11: using supercritical fluid extraction to extract capsaicin in pepper;

[0032] The supercritical fluid extraction technology has been disclosed. The supercritical fluid extraction method has some characteristics of rectification and liquid-liquid extraction. It uses low-temperature CO 2 As an extraction agent, it can effectively prevent the oxidation and dissipation of heat-sensitive substances; in addition, it can extract high-boiling point, low-volatility, and pyrolyzable substances below their boiling point temperature; moreover, the whole process of supercritical fluid extraction does not use Organic solvents, so there is no residual solvent in the extract, and it also prevents the poisoning of the human body and the pollution of the environment during the extraction process.

[0033] S12: 14g gelatin is dissolved in 2800mL distilled water to form a gelatin solution, 2g CMC is dissolved in 400mL distilled water to form a CMC solution, and the gelatin solution an...

Embodiment 2

[0043] S21: Extracting capsaicin from peppers by supercritical fluid extraction;

[0044] S22: 20g gelatin is dissolved in 2000mL distilled water to form a gelatin solution, 2g CMC is dissolved in 200mL distilled water to form a CMC solution, and the gelatin solution and the CMC solution are mixed to form a mixed solution;

[0045] S23: Add 22 g of extracted capsaicin to the mixed solution and complete the emulsification reaction at a speed of 10000 r / min in a tissue grinder to form a first emulsion, and the reaction time of the reaction is 2.5 minutes;

[0046] S24: adjusting the pH of the first emulsion to 4.7 with 10% acetic acid solution and reacting for 40 minutes at 45° C. with a stirring speed of 400 r / min to form a second emulsion.

[0047] S25: under the conditions of step S24, adding 1.54 g of urea to the second emulsion to form a third emulsion;

[0048] S26: Cool the third emulsion to 15°C in an ice-water bath, use 10% sodium hydroxide solution to adjust the pH to...

Embodiment 3

[0051]S31: Extracting capsaicin from peppers by supercritical fluid extraction;

[0052] S32: 22g gelatin is dissolved in 1100mL distilled water to form a gelatin solution, 2g CMC is dissolved in 100mL distilled water to form a CMC solution, and the gelatin solution and the CMC solution are mixed to form a mixed solution;

[0053] S33: Add 32 g of extracted capsaicin to the mixed solution and complete the emulsification reaction at a speed of 8000 r / min in a tissue grinder to form a first emulsion;

[0054] S34: adjusting the pH of the first emulsion to 5 with 10% acetic acid solution and reacting for 40 minutes at 50° C. with a stirring speed of 500 r / min to form a second emulsion.

[0055] S35: under the conditions of step S34, add 2.4 g of oxamide to the second emulsion to form a third emulsion;

[0056] S36: Cool the third emulsion in an ice-water bath to 14°C, use 10% sodium hydroxide solution to adjust the pH to neutral, then add transglutaminase, whose mass percentage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com