Preparation method of machine-made sand concrete regulator

A conditioner and concrete technology, which is applied in the field of concrete admixtures, can solve the problems that stone powder and fine particles cannot be fully saturated with water, concrete collapse performance is deteriorated, and mixing is insufficient, so as to shorten production time, overcome adsorption and consumption, The effect of improving reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

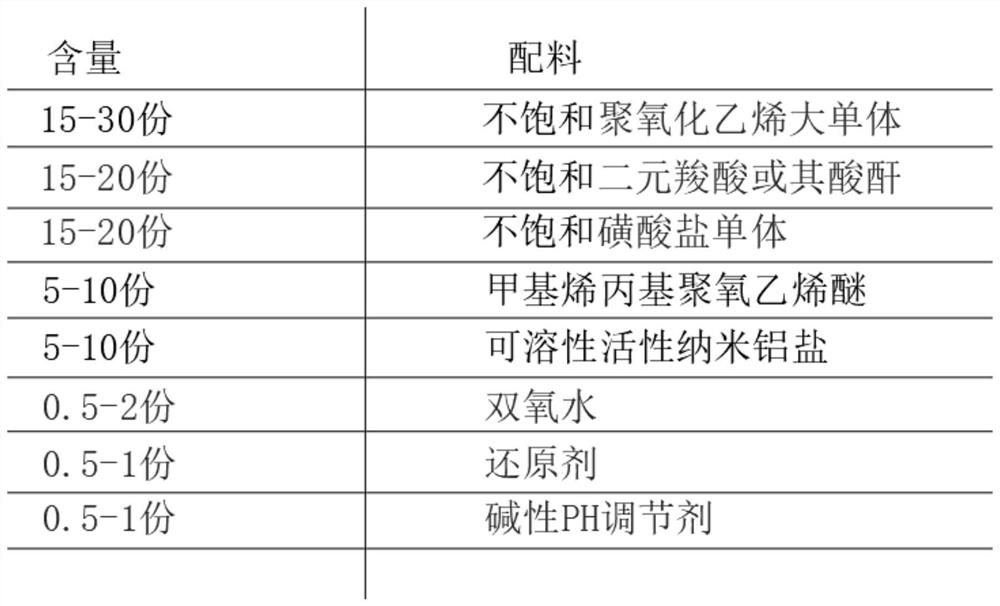

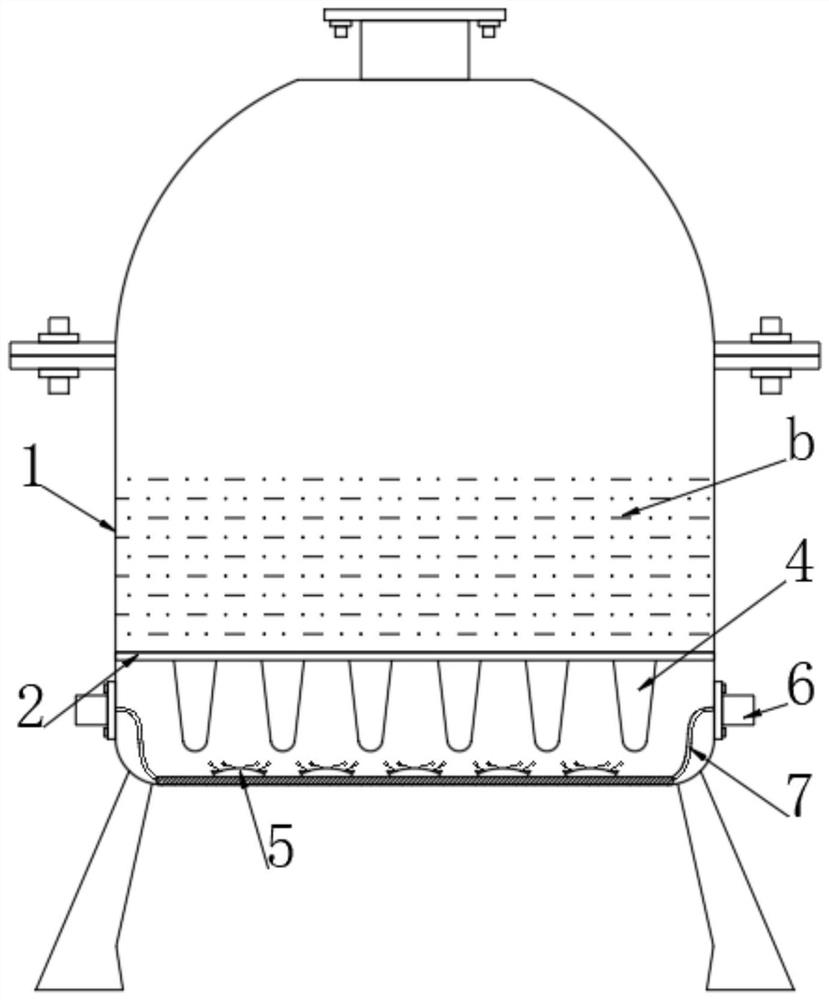

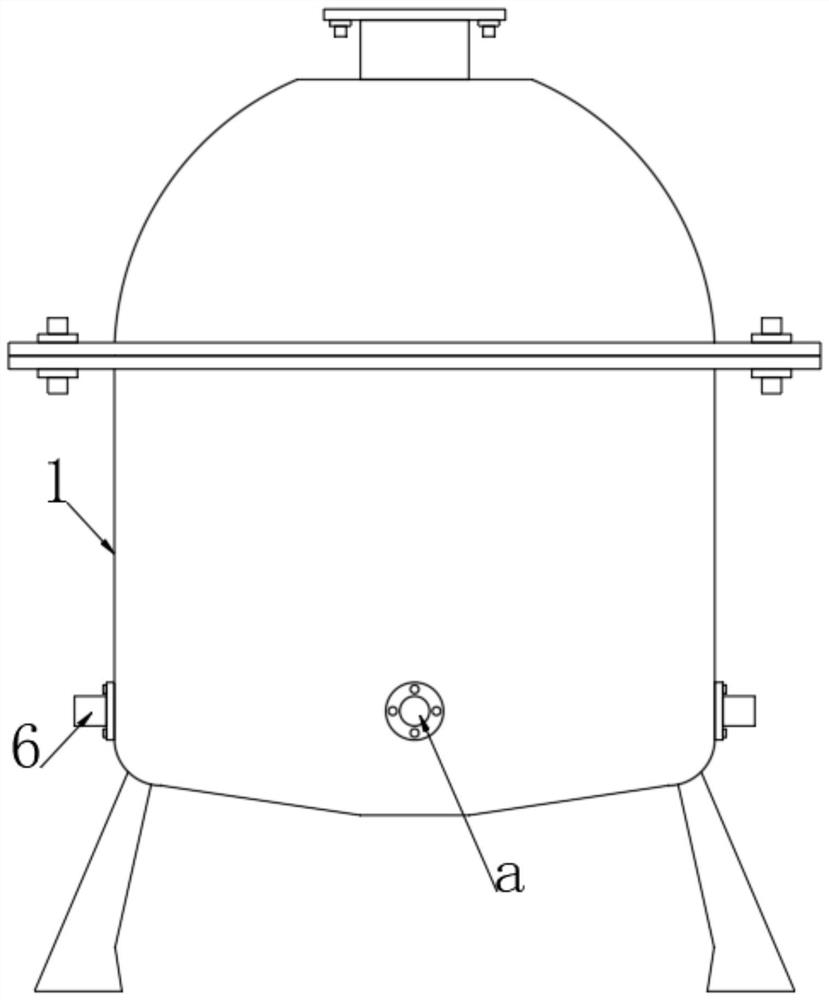

[0043] see figure 1 , a method for preparing a machine-made sand concrete conditioner, the concrete conditioner includes the following ingredients in parts by mass: 15-30 parts of unsaturated polyethylene oxide macromonomer, 15-20 parts of unsaturated dicarboxylic acid or its anhydride, 15-20 parts of unsaturated sulfonate monomer, 5-10 parts of methallyl polyoxyethylene ether, 5-10 parts of soluble active nano-aluminum salt, 0.5-2 parts of hydrogen peroxide, 0.5-1 part of reducing agent, 0.5 -1 part of alkaline pH regulator, preferably with a mass concentration of sodium hydroxide solution below 50%;

[0044] Its preparation method comprises the following steps:

[0045] S1. Add methallyl polyoxyethylene ether, unsaturated polyethylene oxide macromonomer, unsaturated dicarboxylic acid or its anhydride, and unsaturated sulfonate monomer into the reaction vessel, add water to mix, and heat Stir to accelerate dissolution;

[0046] S2. Cool down after dissolving, add hydrogen ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap