Indium phosphide single crystal growth device and method

A growth device and a growth method technology, applied in the field of indium phosphide single crystal growth devices, can solve the problems of repeated maintenance, long use time of stable temperature field, and high difficulty in temperature field control, so as to avoid vibration, reduce production cost, Ease of maintenance and calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

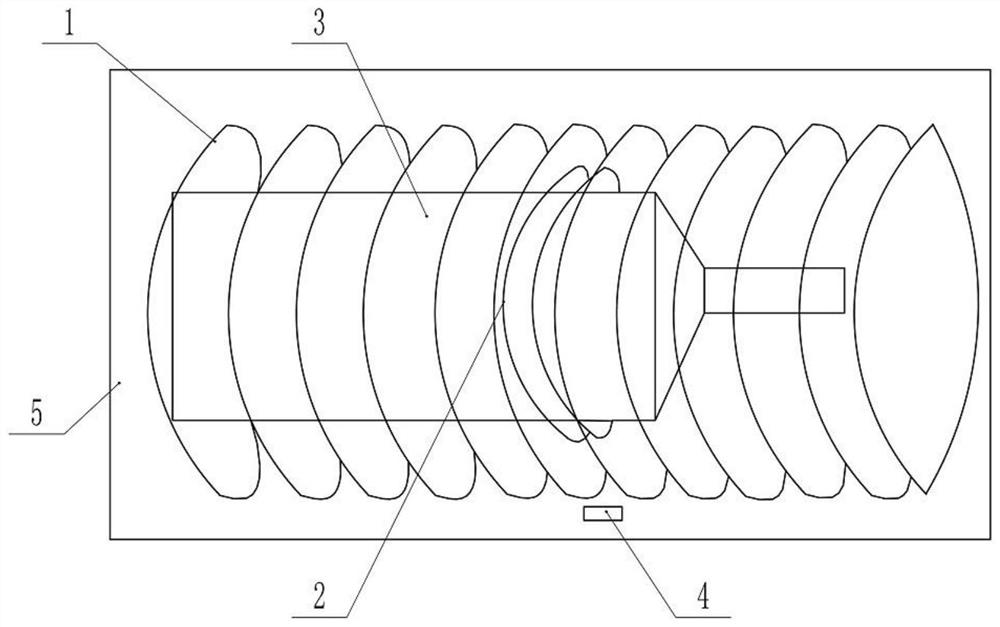

[0038] Such as Figures 1 to 2 As shown, an indium phosphide single crystal growth device includes a fixed heater 1, a movable heater 2, a crystal growth container 3 and an electromagnetic stirring device 4, the fixed heater 1 provides the background temperature for crystal growth, and the movable heater 2 and the electromagnetic stirring device 4 can move outside the crystal growth container 3. Specifically, the mobile heater 2 and the electromagnetic stirring device 4 are connected to three high-temperature-resistant screw rods, and the screw rods are driven by a motor, thereby realizing the mobile heater 2 and the electromagnetic stirring device 4. The movement of the stirring device 4; the electromagnetic stirring device 4 is used to generate a circulation in the melt of indium phosphide, so that the grown single crystal is more uniform.

[0039]In one embodiment, the fixed heater 1 , the movable heater 2 , the crystal growth container 3 and the electromagnetic stirring de...

Embodiment 2

[0043] Another aspect of the present invention also provides a method for growing an indium phosphide single crystal, the specific steps are as follows:

[0044] S1. Put the seed crystal into the seed crystal area of the crystal growth container 3;

[0045] S2. Put the indium phosphide polycrystalline material and auxiliary materials into the crystal growth container 3 (the filling height is generally no more than three-quarters of the diameter of the crystal growth container 3), and the auxiliary materials are covering agents and phosphorus supplements;

[0046] S3. Put the crystal growth container 3 in S2 into the horizontal furnace 5, and fill the horizontal furnace 5 with electronic grade argon;

[0047] S4, moving the mobile heater 2 so that it is on the same vertical plane as the seed crystal area;

[0048] S5. Turn on the fixed heater 1 and the mobile heater 2 at the same time, set the target temperature to 750°C, and heat up to the target temperature at a heating ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com