Tellurium-cadmium-mercury liquid phase epitaxial growth source substrate and preparation method thereof and tellurium-cadmium-mercury liquid phase epitaxial growth method

A liquid phase epitaxy and epitaxy growth technology, which is used in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of uneven temperature field, and the thermal conductivity of transmission substrate materials cannot meet the temperature control conduction well. Achieve the effect of improving temperature field control ability, ensuring uniform heat conduction processing ability, and low half-peak width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

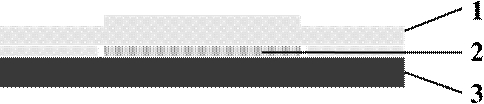

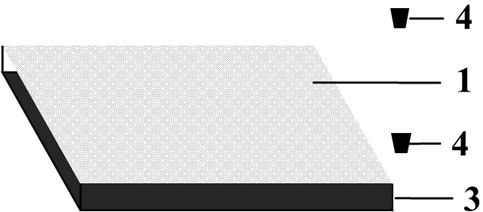

[0036] A substrate of a mercury cadmium telluride liquid phase epitaxial growth source, comprising a cadmium zinc telluride substrate and a multilayer complex coating, the multilayer complex coating is loaded on the top of the cadmium zinc telluride substrate body, and the multilayer complex The coating is alternately deposited on the top of the CdZnTe substrate body by spray electrodeposition, the multilayer complex coating is a copper / nickel complex coating, and the molar ratio of copper to nickel is 2:8, and the substrate body is The cadmium zinc telluride substrate has a size of 2 cm×3 cm, and the resistivity of the cadmium zinc telluride substrate is 108˜148 Ω·m.

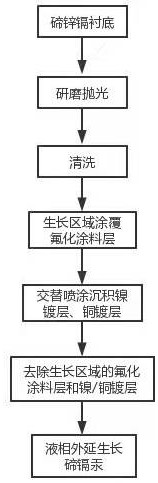

[0037] The substrate of the above-mentioned mercury cadmium telluride liquid phase epitaxial growth source, the specific process flow chart is as follows figure 1 Shown, its preparation method comprises:

[0038] (1) Prepare the CdZnTe substrate. The specific processing method includes: grinding and polishing ...

Embodiment 2

[0047] In one embodiment, the present invention also provides a CdZnTe liquid phase epitaxial growth source substrate, comprising a CdZnTe substrate and a multilayer complex coating, and the multilayer complex coating is supported on a CdZnTe substrate Bottom top, described multilayer complex coating is alternately deposited on the cadmium zinc telluride substrate top by spray electrodeposition, and described multilayer complex coating is copper / nickel complex coating, and the mol ratio of copper and nickel is 4: 6.

[0048] The substrate of the above-mentioned mercury cadmium telluride liquid phase epitaxial growth source, its preparation method comprises:

[0049] (1) Prepare the CdZnTe substrate. The specific processing methods include: grinding and polishing the 111 crystal phase surface of the CdZnTe substrate with 1% bromomethanol, then rinsing with isopropanol solution and blowing dry with a nitrogen gun. A certain oxygen pressure is set outside, and the copper and nic...

Embodiment 3

[0058] In one embodiment, the present invention also provides a substrate material for a CdZnTe liquid-phase epitaxial growth source, comprising a CdZnTe substrate and a multilayer complex coating, the multilayer complex coating loaded on ZnTe On the top of the cadmium substrate, the multilayer complex coating is alternately deposited on the top of the cadmium zinc telluride substrate by spray electrodeposition, the multilayer complex coating is a copper / nickel complex coating, and the molar ratio of copper to nickel is 7:5.

[0059] The substrate of the above-mentioned mercury cadmium telluride liquid phase epitaxial growth source, its preparation method comprises:

[0060] (1) Prepare the CdZnTe substrate. The specific processing methods include: grinding and polishing the 111 crystal phase surface of the CdZnTe substrate with 1% bromomethanol, then rinsing with isopropanol solution and blowing dry with a nitrogen gun. A certain oxygen pressure is set outside, and the coppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com