Method for recycling scrapped low-pressure membrane based on interface wettability regulation, and polyamide nanofiltration membrane prepared by method

An interface wetting, low-pressure membrane technology, applied in the field of membrane separation, can solve the problems of low absorption efficiency of amine monomers, hinder the regeneration and upgrading of scrapped membranes, etc., and achieve the effect of promoting resource recycling, easy implementation, and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

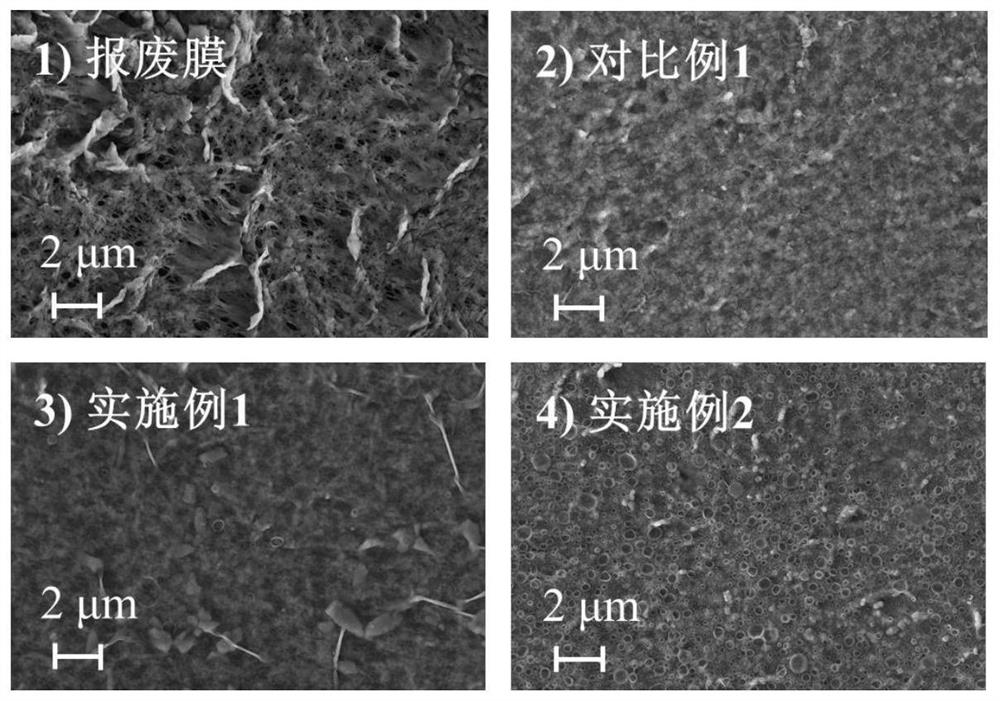

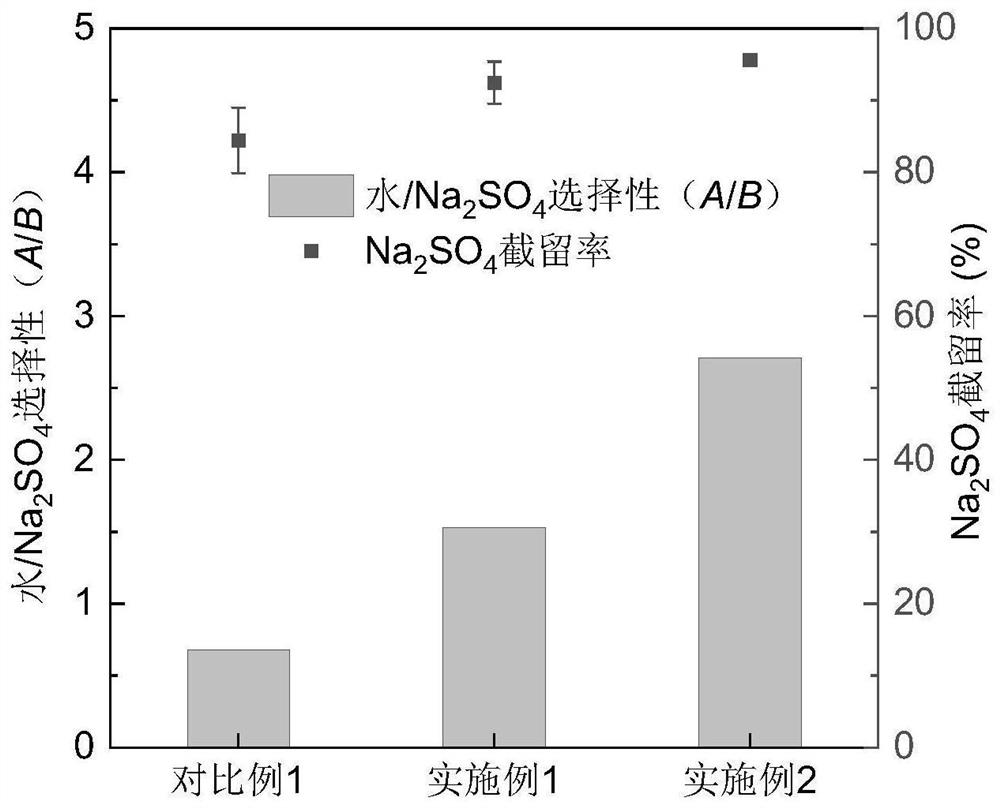

[0035] Based on interfacial moisture regulation upgrade regenerative scrap PVDF microfiltration membrane preparation nanofiltration membrane: 10 min hydrofiltration membrane is first carried out, remove large block layers attached to the surface, and dry the surface with suction paper. The microstructure was treated with a microfiltration membrane in aqueous solution containing 0.2 wt / V% piperazine and 0.25 cmc dodecyl benzene sulfonate, and excess droplets were removed by the rubber roller, and then 0.16 wt / v % Of the phenamphthal chloride-n-hexane solution treatment of microfiltration membrane 30s, pour the solution, dry 1 min, and place the diaphragm at 60 ° C heat treatment for 5 min.

[0036] through figure 1 The scanned electron microscope shown can be observed, and the surface of the scrap microfilter forms a continuous uniform dense polyamide trap layer.

Embodiment 2

[0038]Based on interfacial moisture regulation upgrade regenerative scrap PVDF microfiltration membrane preparation nanofiltration membrane: 10 min hydrofiltration membrane is first carried out, remove large block layers attached to the surface, and dry the surface with suction paper. The microfiltration membrane was treated in aqueous solution containing 0.2 wt / v% piperazine and 1.0 cmc dodecyl benzene sulfonate, and excess droplets were removed by rubber rollers, and then 0.16 wt / v was used. % Of the phenamphthal chloride-n-hexane solution treatment of microfiltration membrane 30s, pour the solution, dry 1 min, and place the diaphragm at 60 ° C heat treatment for 5 min.

[0039] through figure 1 The scanned electron microscope shown can be observed, and the surface of the scrap microfilter forms a continuous uniform dense polyamide trap layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com