Ultra-thick graphite heat-conducting film as well as preparation method and application thereof

A graphite heat-conducting film, ultra-thick technology, applied in chemical instruments and methods, electrical equipment structural parts, cooling/ventilation/heating transformation, etc., can solve the problem of affecting the performance of graphite film and downstream applications, difficult gas discharge, powder drop, etc. Problems, to avoid product delamination, high compressive strength, high thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

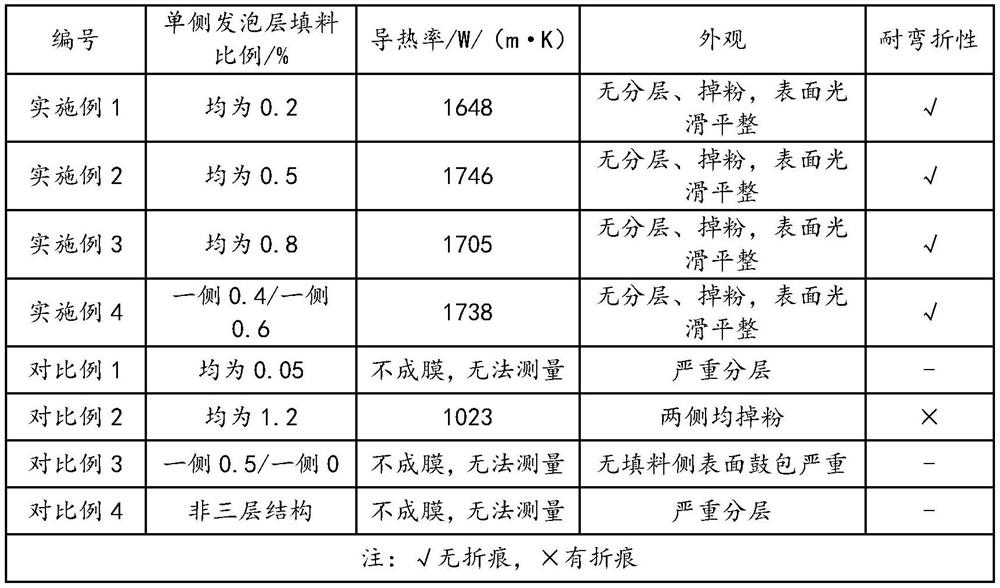

Examples

Embodiment 1

[0046] (1) Synthesis of core layer resin: 200.2g of 4,4'-diaminodiphenyl ether and 218g of pyromellitic dianhydride were successively added to 1.67kg of N,N-dimethylformamide, and the polycondensation reaction was carried out for 2 hours to obtain Core resin;

[0047] (2) Synthesis of foam layer resin: Add 200.2g of 4,4'-diaminodiphenyl ether and 218g of pyromellitic dianhydride to 1.67kg of N,N-dimethylformamide in sequence, and conduct polycondensation reaction for 2 hours. Then add 0.84 g of calcium hydrogen phosphate (particle size 500 nm) dispersed by ultrasonic waves, and conduct polycondensation reaction for 2 hours to obtain foamed layer resin;

[0048] (3) After vacuum defoaming, add chemical imidization reagents to the core layer and foam layer resin respectively, specifically add 204.2g of acetic anhydride and 25.8g of isoquinoline, and send them to the three-layer co-extrusion die head Extrusion-type film production, the middle is imidized resin for the core layer...

Embodiment 2

[0051] (1) Synthesis of core layer resin: 200.2 g of 4,4'-diaminodiphenyl ether and 218 g of pyromellitic dianhydride were sequentially added to 1.67 kg of N,N-dimethylformamide, and the polycondensation reaction was carried out for 2 hours;

[0052] (2) Synthetic foam layer resin: on the basis of the core layer resin formula, add 2.1 g of calcium hydrogen phosphate (particle size 500nm) dispersed through ultrasonic, and polycondense for 2 hours;

[0053] (3) After vacuum degassing, add chemical imidization reagents to the core layer and the foam layer resin respectively, specifically add 204.2g of acetic anhydride and 25.8g of isoquinoline, then core layer imidization resin and The imidized resin of the foaming layer is sent to the three-layer co-extrusion die for extrusion film making, the middle is the imidized resin of the core layer, and the imidized resin of the foaming layer is used on both sides, and the polyimide produced by extrusion is The thickness of the amine fil...

Embodiment 3

[0056] (1) Synthesis of core layer resin: 200.2 g of 4,4'-diaminodiphenyl ether and 218 g of pyromellitic dianhydride were sequentially added to 1.67 kg of N,N-dimethylformamide, and the polycondensation reaction was carried out for 2 hours;

[0057] (2) Synthetic foam layer resin: on the basis of the core layer resin formula, add 3.35 g of calcium hydrogen phosphate (particle size 500nm) dispersed through ultrasonic, and polycondense for 2 hours;

[0058] (3) After vacuum degassing, add chemical imidization reagents to the core layer and the foam layer resin respectively, specifically add 204.2g of acetic anhydride and 25.8g of isoquinoline, then core layer imidization resin and The imidized resin of the foaming layer is sent to the three-layer co-extrusion die for extrusion film making, the middle is the imidized resin of the core layer, and the imidized resin of the foaming layer is used on both sides, and the polyimide produced by extrusion is The thickness of the amine fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com