Preparation method of super-hydrophobic filter paper for oil-water separation

An oil-water separation and super-hydrophobic technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of cumbersome preparation, high production cost, complicated process, etc., and achieve the effect of simple process and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Mix the attapulgite clay and the pulp evenly under high-speed stirring to obtain a mixed slurry, filter the mixed slurry, flatten it and dry it to obtain a filter paper containing attapulgite clay. The content of attapulgite clay in the filter paper is 1%.

[0025] (2) Pour methyltrimethoxysilane into an open container and put it together with the filter paper prepared in step (1) into a closed oven with a condensing device. The oven was heated to 50°C for hydrophobic modification for 4 hours, and the organic vapor generated during the modification process was recovered by a condensing device, and finally the oven was opened to obtain superhydrophobic filter paper.

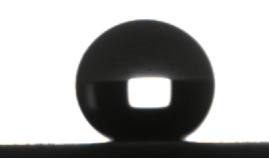

[0026] The prepared superhydrophobic filter paper has a water contact angle of 152° and can repeat oil-water separation for 550 times.

Embodiment 2

[0028] (1) Mix the attapulgite clay and the pulp evenly under high-speed stirring to obtain a mixed slurry, filter the mixed slurry, flatten it and dry it to obtain a filter paper containing attapulgite clay. The content of attapulgite clay in the filter paper is 2%.

[0029] (2) Pour methyltriethoxysilane into an open container and put it together with the filter paper prepared in step (1) into a closed oven with a condensing device. The oven was heated to 60°C for hydrophobic modification for 3 hours, and the organic vapor generated during the modification process was recovered by a condensing device, and finally the oven was opened to obtain superhydrophobic filter paper.

[0030] The prepared superhydrophobic filter paper has a contact angle of 158° to water, and can repeat oil-water separation 600 times.

Embodiment 3

[0032] (1) Mix the attapulgite clay and the pulp evenly under high-speed stirring to obtain a mixed slurry, filter the mixed slurry, flatten it and dry it to obtain a filter paper containing attapulgite clay. The content of attapulgite clay in the filter paper is 5%.

[0033] (2) Pour vinyltriethoxysilane into an open container and put it together with the filter paper prepared in step (1) into a closed oven with a condensing device. The oven was heated to 100°C for hydrophobic modification for 0.5h, and the organic vapor generated during the modification process was recovered by a condensing device, and finally the oven was opened to obtain superhydrophobic filter paper.

[0034] The prepared superhydrophobic filter paper has a contact angle of 168° to water, and can repeat oil-water separation for 1000 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com