Organic modified montmorillonite composite material and application thereof

A technology of composite materials and montmorillonite, which is applied in the field of organically modified montmorillonite composite materials, can solve the problems of secondary pollution and low heavy metal adsorption efficiency, achieve low equipment requirements, simple and easy preparation process, and improve adsorption effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

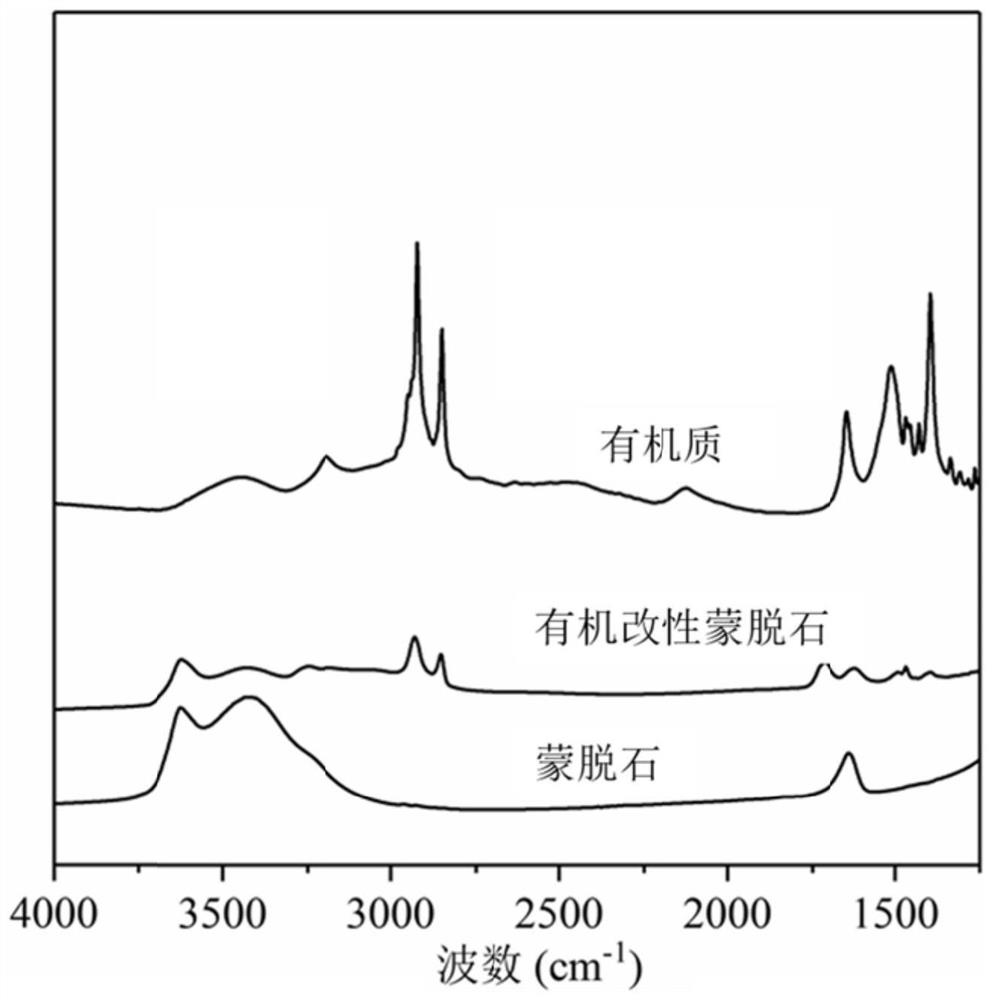

[0057] In this example, the steps for preparing the organically modified montmorillonite composite material are as follows:

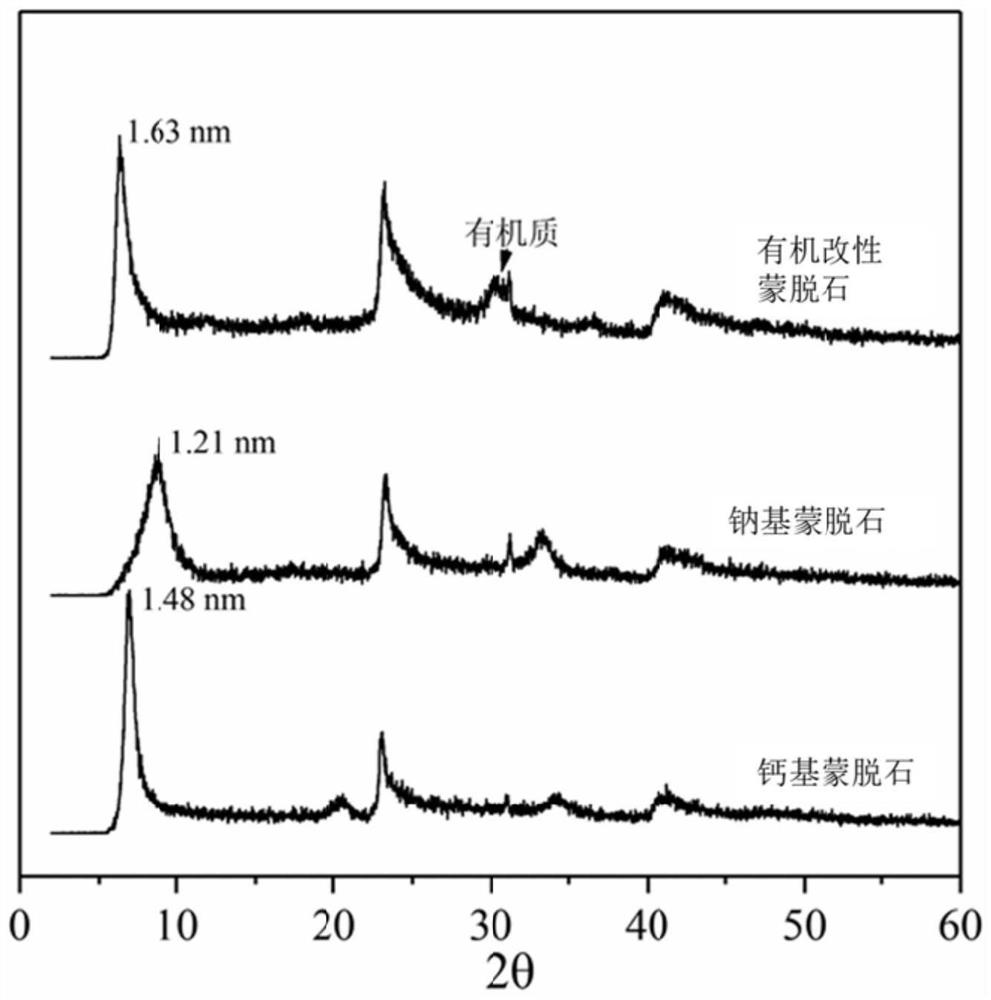

[0058] (1) Take the montmorillonite raw material, the montmorillonite raw material is calcium-based montmorillonite, pulverize, pass through a 200-mesh sieve, settle and purify to obtain montmorillonite powder.

[0059] (2) Get the montmorillonite powder that 10g step (1) obtains, add 200mL concentration and be in the sodium chloride solution of 0.5mol / L, stir on the magnetic stirrer, the rotating speed is 550rpm, and the temperature is constant at 80 ℃; After 24h, put The montmorillonite is separated from the solution, and fresh sodium chloride solution is added again, and the exchange is repeated twice; the solution after the cation exchange is centrifuged, and the solid residue is washed with deionized water, and detected with silver nitrate solution until there is no chloride ion , to obtain sodium-based montmorillonite, which was stored after freez...

Embodiment 2

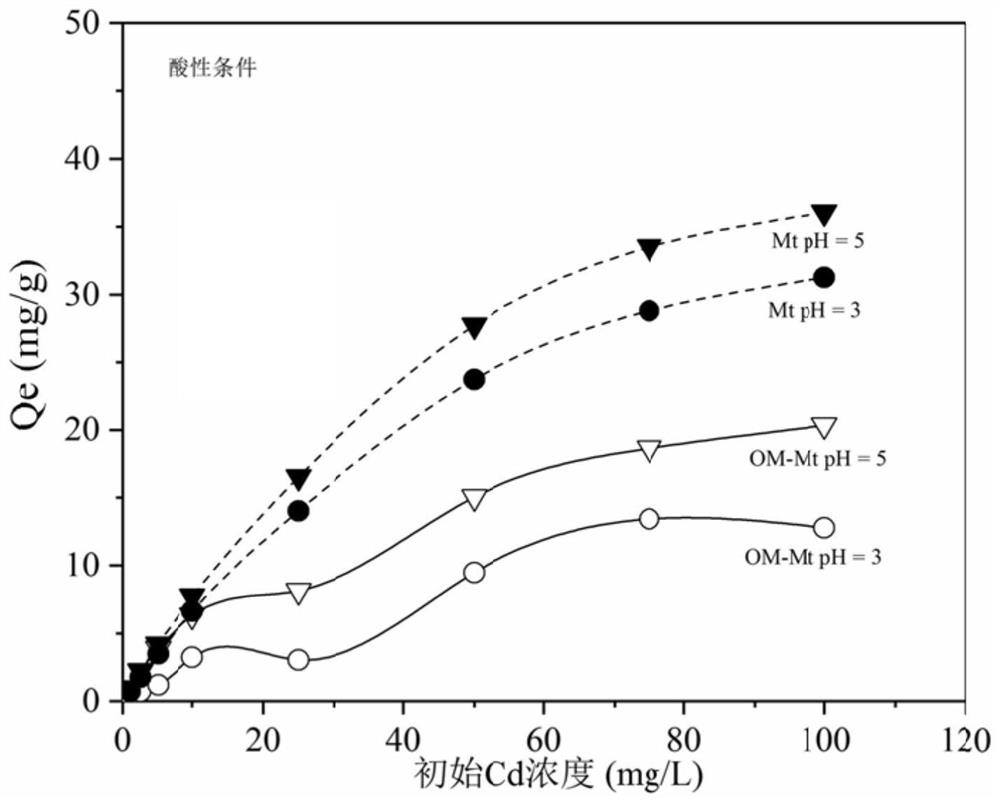

[0067] In this case, the organically modified montmorillonite composite material adsorbs cationic heavy metal cadmium, and the steps are as follows:

[0068] (1) With cadmium nitrate (Cd(NO 3 ) 2 ) is Cd 2+ source, prepare 50.0mL of Cd 2+ Solution, the concentration is set to 1mg / L, 5mg / L, 10mg / L, 25mg / L, 50mg / L, 75mg / L, 100mg / L, and the pH value of the solution is adjusted to 3.0 and 5.0.

[0069] (2) Weigh 50 mg of the organically modified montmorillonite composite material prepared in Example 1, add it to the prepared solution, and centrifuge after fully shaking and reacting for 24 hours. The supernatant is filtered with a 0.22 micron water filter head, and the filtrate is Preserve and test the Cd concentration using an inductively coupled plasma emission spectrometer; the measured pH value is 3.0, the saturated adsorption capacity of the organically modified montmorillonite composite material to Cd is 13.99 mg / g, and the pH value is 5.0. The saturated adsorption capaci...

Embodiment 3

[0074] In this case, the organically modified montmorillonite composite material adsorbs cationic heavy metal cadmium, and the steps are as follows:

[0075] (1) With cadmium nitrate (Cd(NO 3 ) 2 ) is Cd 2+ source, prepare 50.0mL of Cd 2+ solution, the concentration is set to 1mg / L, 5mg / L, 10mg / L, 25mg / L, 50mg / L, 75mg / L, 100mg / L, and the pH value of the solution is adjusted to 7.0.

[0076] (2) Weigh 50 mg of the organically modified montmorillonite composite material prepared in Example 1, add it to the prepared solution, and centrifuge after fully shaking and reacting for 24 hours. The supernatant is filtered with a 0.22 micron water filter head, and the filtrate is Save and test the Cd concentration by inductively coupled plasma optical emission spectrometer; the measured pH value is 7.0, the saturated adsorption capacity of organically modified montmorillonite composite material for Cd is 21.17mg / g.

[0077] The schematic diagram of the adsorption capacity of organically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com