Self-suction oil-water separating device

An oil-water separation device, self-priming technology, applied in the direction of liquid separation, separation method, semi-permeable membrane separation, etc., can solve the problems of low separation rate, unfriendly environment, high operating cost, etc., to achieve improved separation rate and low operating cost , good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

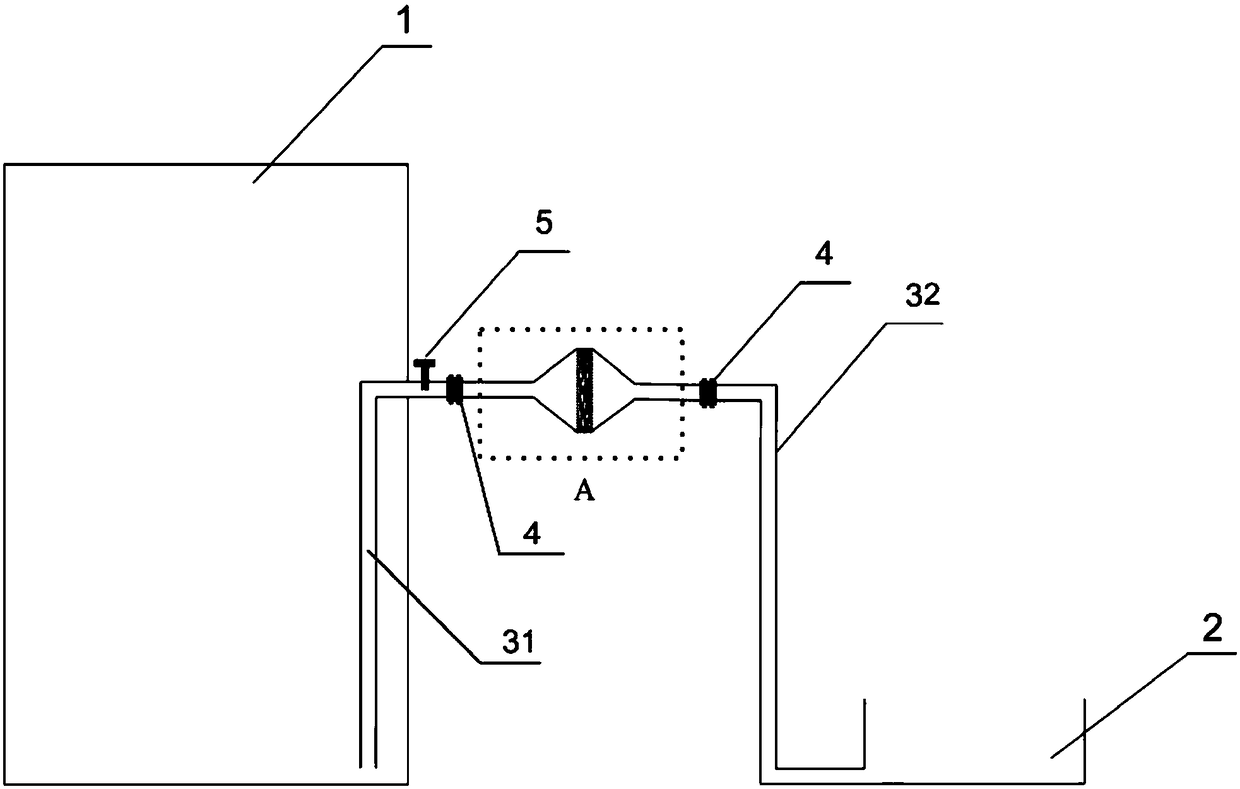

[0037] In this embodiment, the specific construction steps of the self-priming oil-water separation device are as follows:

[0038] (1) Carry out anodic oxidation under voltage 40V with diameter 20mm, thick 3mm, the foamed titanium of filter precision 30 μ m, anodic oxidation time is 3h, and electrolytic solution is the mixed solution of the ethylene glycol that contains 0.2wt% ammonium fluoride and water ( The mass fraction of water is 20%), then dried and annealed at 450° C. for 3 h.

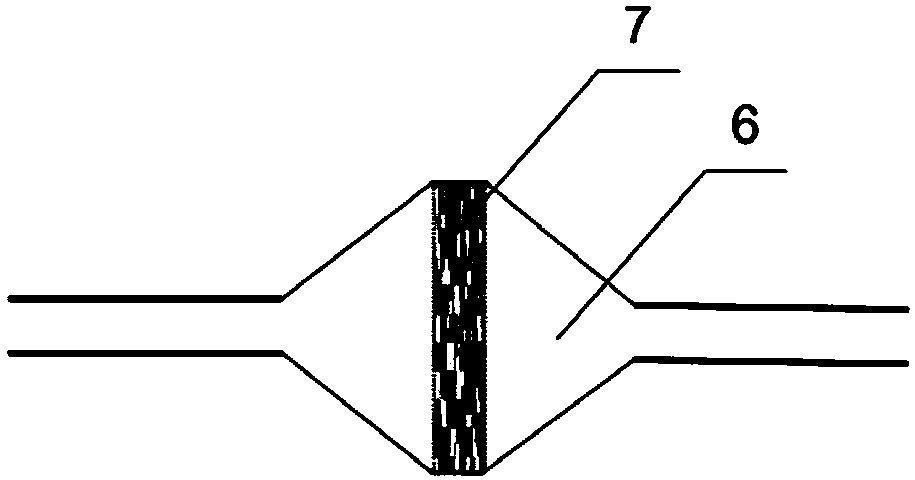

[0039](2) Embed the anodized titanium foam into the bottom of the quartz conical funnel, seal and fix it with silicone glue, apply silicone glue on the connection, buckle another identical conical funnel, and Wait for the glue to solidify to form a spindle-shaped filter chamber with a separation membrane embedded in it.

[0040] (3) An inverted L-shaped quartz tube with an outer diameter of 7 mm and an inner diameter of 3 mm is introduced into the side wall opening of a quartz liquid storage ...

Embodiment 2

[0049] The difference from Example 1 is:

[0050] 1. The metal foam used in step (1) is aluminum foam, the electrolytic solution for anodic oxidation is 2.7wt% oxalic acid solution, and the anodic oxidation time is 15 minutes. Anodized aluminum foam surface microstructure see figure 2 (b).

[0051] 2. Use the same steps as in Example 1 to build an oil-water separation device.

[0052] Through the self-priming oil-water separation device, the separation efficiency of the oil-in-water emulsion of n-hexane can reach more than 99.5%.

Embodiment 3

[0054] The difference from Example 1 is:

[0055] 1. The titanium foam filtration precision parameter used in step (1) is 10 μm.

[0056] 2. Use the same steps as in Example 1 to build an oil-water separation device.

[0057] Through the self-priming oil-water separation device, the separation efficiency of n-hexane oil-in-water emulsion can reach more than 99.95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com