Preparation method and application of magnetic adsorbent for efficiently removing elemental mercury and hydrogen sulfide

A magnetic adsorbent and elemental mercury technology, applied in the field of flue gas purification, can solve the problems of no mercury removal technology, restricted application, high price, etc., achieve good collection and recycling conditions, fast mercury adsorption rate, high adsorption rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The present invention, the preparation method of magnetic adsorbent, specifically comprises the following steps:

[0035] The first step is to wash and air-dry the salvaged Enteromorpha, grind it into 100-mesh particles, weigh 10g of Enteromorpha and add it to a sodium alginate solution with an optimal concentration of 0.03mol / L, and stir it magnetically;

[0036] In the second step, after magnetic stirring for 4 hours, drop into 1 L of ferric nitrate solution with a concentration of 0.1 wt%, and then freeze-dry the obtained sample in a vacuum freeze dryer for 24 hours;

[0037] The third step is to put the sample taken out into a fixed bed and set the pyrolysis temperature to 600°C for 0.5h, during which a nitrogen protective gas with a flow rate of 1L / min is introduced;

[0038] In the fourth step, 100ppm of H 2 S gas is passed through the fixed bed for 1 hour, and then 1 L / min nitrogen flow is used for flushing for 0.5 hour to obtain the magnetic adsorbent.

[0039...

Embodiment 2

[0045] The difference from Example 1 is:

[0046] The pyrolysis temperature in the third step is 650°C.

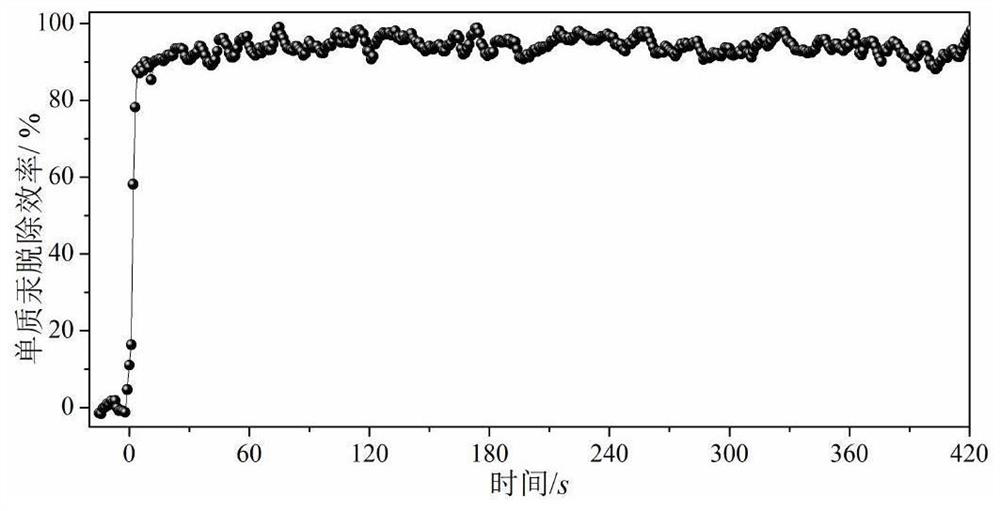

[0047] The magnetic adsorbent prepared in this example was subjected to a mercury removal experiment. The specific steps were the same as in Example 1. After 1 hour of reaction, the removal efficiency of elemental mercury reached 95%, and the obtained sample was magnetic both before and after the reaction.

Embodiment 3

[0049] The difference from Example 1 is:

[0050] The pyrolysis temperature in the third step is 750°C.

[0051] The magnetic adsorbent prepared in this example was subjected to a mercury removal experiment. The specific steps were the same as in Example 1. After 1 hour of reaction, the removal efficiency of elemental mercury reached 93%, and the obtained sample was magnetic both before and after the reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com