Continuous casting crystallizer casting powder as well as preparation method and application thereof

A continuous casting crystallizer and mold slag technology, which is applied in the field of metallurgy to achieve the effects of reducing heat dissipation, reducing the thermal stress of the slab, and uniform growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

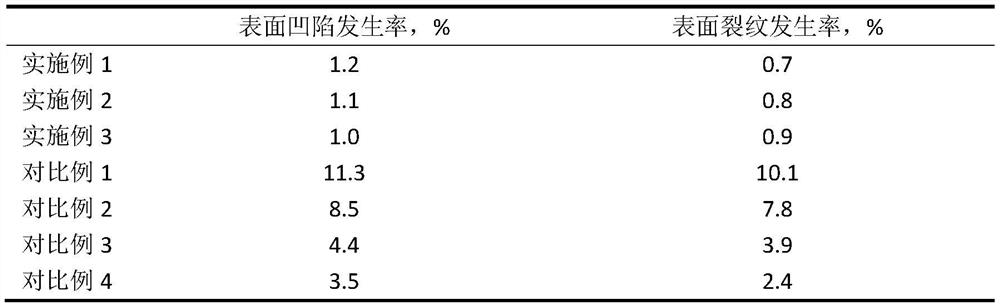

Examples

Embodiment 1

[0033] This embodiment provides a continuous casting mold powder, which is composed of the following chemical components in mass percentage: SiO 2 : 40%, CaO: 38%, MgO: 1.5%, Al 2 o 3 : 6%, Na 2 O: 5%, F: 5%, C: 3%, and the rest are unavoidable impurities;

[0034] The binary basicity of the mold flux CaO / SiO 2 It is 0.95, the melting point is 1120°C, and the viscosity at 1300°C is 2.5Pa·s.

[0035] The preparation method of described mold powder comprises the following steps:

[0036]S1: Weigh calcium silicate refining slag, calcium aluminate refining slag, limestone, bauxite, sodium fluoride, magnesia, quartz sand, fluorite, and graphite according to the above formula ratio, and put them into the mixer to fully Mixing, the mixing time is 10min, the rotating speed of the mixer is 40r / min, and the mixed dry material is obtained, and then starch binder with a mass of 2% of the mixed dry material is added, stirred and mixed, and the mixed raw material is obtained;

[0037]...

Embodiment 2

[0040] This embodiment provides a continuous casting mold powder, which is composed of the following chemical components in mass percentage: SiO 2 : 35%, CaO: 35%, MgO: 2.2%, Al 2 o 3 : 5%, Na 2 O: 8%, F: 8%, C: 5%, and the rest are unavoidable impurities;

[0041] The binary basicity of the mold flux CaO / SiO 2 1.00, the melting point is 1140°C, and the viscosity at 1300°C is 2.0 Pa·s.

[0042] The preparation method of described mold powder comprises the following steps:

[0043] S1: Weigh calcium silicate refining slag, calcium aluminate refining slag, limestone, bauxite, sodium fluoride, magnesia, quartz sand, fluorite, graphite according to the above formula ratio, and then put them into the mixer Fully mix, the mixing time is 12min, and the speed of the mixer is 32 rpm to obtain a mixed dry material, then add a dextrin binder with a mass of 2.5% of the mixed dry material, stir and mix, and obtain a mixed raw material;

[0044] S2: add water to the mixed raw material...

Embodiment 3

[0047] This embodiment provides a continuous casting mold powder, which is composed of the following chemical components in mass percentage: SiO 2 : 38%, CaO: 40%, MgO: 1.8%, Al 2 o 3 : 4%, Na 2 O: 6%, F: 6%, C: 4%, and the rest are unavoidable impurities;

[0048] The binary basicity of the mold flux CaO / SiO 2 It is 1.05, the melting point is 1160°C, and the viscosity at 1300°C is 1.5Pa·s.

[0049] The preparation method of described mold powder comprises the following steps:

[0050] S1: Weigh calcium silicate refining slag, calcium aluminate refining slag, limestone, bauxite, sodium fluoride, magnesia, quartz sand, fluorite, graphite according to the above formula ratio, and then put them into the mixer Fully mix, the mixing time is 15 minutes, and the speed of the mixer is 25 rpm to obtain a mixed dry material, then add a carboxymethyl cellulose binder with a mass of 3.0% of the mixed dry material, stir and mix, and obtain a mixed raw material;

[0051] S2: Add water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com