Production system for engineering auxiliary facility steel structure fixing fasteners and recycling method

A technology for auxiliary facilities and production systems, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of hidden safety accidents, low yield of fasteners, easy to cause internal injuries, etc., to prevent hidden safety accidents, The processing method is scientific and the effect of improving the processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

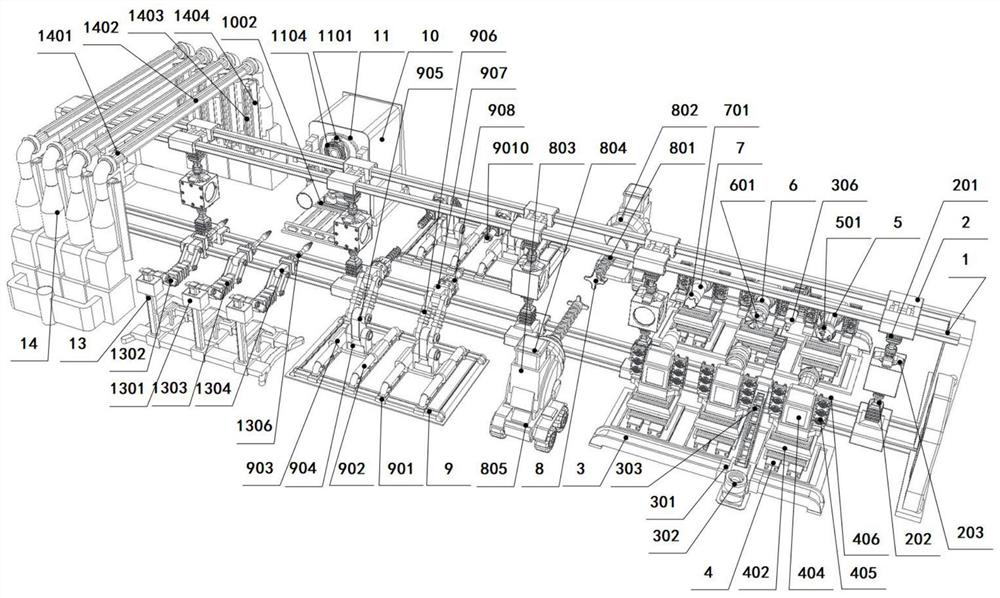

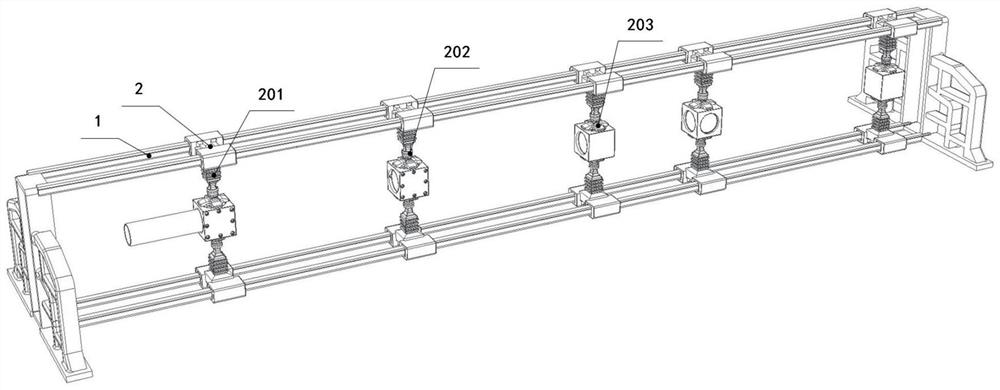

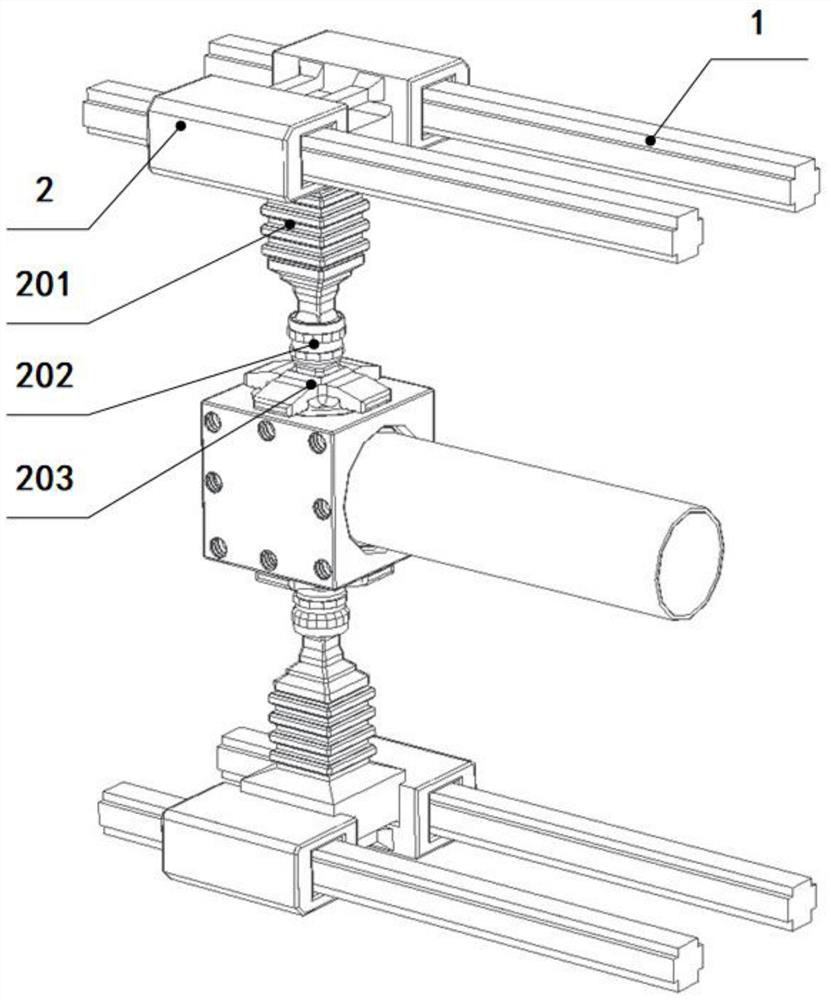

[0048] see Figure 1-11 , the production system of steel structure fixed fasteners for engineering auxiliary facilities, including the mobile system, the slotting system set on both sides below the mobile system, the clamping system, the hole opening system, the assembly system, and the high temperature system set above the mobile system; The slotting system, the clamping system, and the opening system are two and symmetrically arranged on both sides below the moving system. The slotting system includes a liquid spray mechanism and several slotting mechanisms; the assembly system includes an intubation mechanism and several locks. The tightening mechanism is located on both sides of the lower part of the mobile system;

[0049] During work, the moving system is used to fix and move the raw materials to each system for corresponding process operations. The mobile grabbing mechanism can not only clamp and fix the raw materials, but also realize the flipping of the raw materials ...

Embodiment 2

[0060] The present invention also relates to a recycling method for the production system of the steel structure fixing fasteners of the above-mentioned engineering auxiliary facilities. The recycling method specifically includes the following steps:

[0061] (1) The raw material is placed between the grippers 203 of the two symmetrically arranged mobile grabbing mechanisms, grasped and fixed by the grippers 203, and the installation of the raw material is completed;

[0062] (2) Move the raw material to the slotting system through the moving system for slotting. The slotting adopts three components and three sections for slotting. The slotting system slots the four sides of the raw material respectively; there are three different models The drill bit of the same size slots the side of the raw material to obtain a slot of a preset shape;

[0063] Specifically, three different types of drill bits of the slotting mechanism are used to drill and slot in turn. During the slotting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com