Quick-drying high-strength thin spraying material and preparation method thereof

A fast-drying, high-strength technology, applied in the field of thin spray materials, can solve the problems of low compressive and flexural strength of spray materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

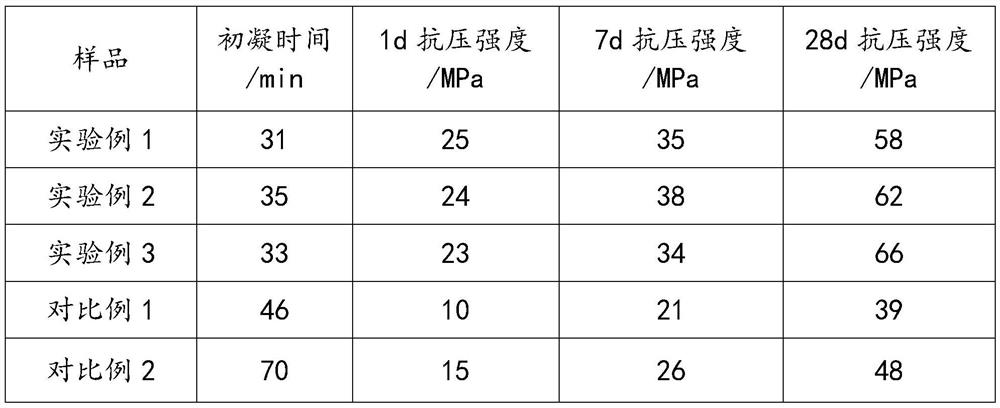

Examples

Embodiment 1

[0039] This embodiment is a quick-drying high-strength thin-spray material, which is specifically prepared by the following steps:

[0040] S1: Add sand, professional cement and stabilizer to the mixing equipment, and stir for 5 minutes;

[0041] S2: Add special formula admixture and micropowder, keep the rotation speed at 30 rpm, stir for 8 minutes, add accelerator, increase the rotation speed to 45 rpm, and stir for 2 minutes to obtain spare materials;

[0042] S3: Use a spray pump to spray the spare material on the desired position, the spray thickness is 15mm, and the use is 30kg per square meter. After curing, the fast-drying high-strength thin spray material is obtained;

[0043] Wherein foaming agent is obtained by following preparation steps:

[0044] S31: Add diethanolamine into the three-necked flask, add the solvent N,N-dimethylacetamide, blow in nitrogen gas, turn on the magnetic stirrer, add succinic anhydride into the solvent N,N-dimethylacetamide, and Dissolve c...

Embodiment 2

[0053] This embodiment is a quick-drying high-strength thin-spray material, which is specifically prepared by the following steps:

[0054] S1: Add sand, professional cement and stabilizer to the mixing equipment, and stir for 8 minutes;

[0055] S2: Add special formula admixture and micropowder, keep the rotation speed at 30 rpm, stir for 8 minutes, add accelerator, increase the rotation speed to 45 rpm, and stir for 2 minutes to obtain spare materials;

[0056] S3: Use a spray pump to spray the spare material on the required position, the spray thickness is 20mm, and the use is 42kg per square meter. After curing, the fast-drying high-strength thin spray material is obtained;

[0057] Wherein foaming agent is obtained by following preparation steps:

[0058] S31: Add diethanolamine into the three-necked flask, add the solvent N,N-dimethylacetamide, blow in nitrogen gas, turn on the magnetic stirrer, add succinic anhydride into the solvent N,N-dimethylacetamide, and Dissolv...

Embodiment 3

[0067] This embodiment is a quick-drying high-strength thin-spray material, which is specifically prepared by the following steps:

[0068] S1: Add sand, professional cement and stabilizer to the mixing equipment, and stir for 10 minutes;

[0069] S2: Add special formula admixture and micropowder, keep the rotation speed at 30 rpm, stir for 8 minutes, add accelerator, increase the rotation speed to 45 rpm, and stir for 2 minutes to obtain spare materials;

[0070] S3: Use a spray pump to spray the spare material on the required position, the spray thickness is 20mm, and the use is 42kg per square meter. After curing, the fast-drying high-strength thin spray material is obtained;

[0071] Wherein foaming agent is obtained by following preparation steps:

[0072] S31: Add diethanolamine into the three-necked flask, add the solvent N,N-dimethylacetamide, blow in nitrogen gas, turn on the magnetic stirrer, add succinic anhydride into the solvent N,N-dimethylacetamide, and Dissol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com